A kind of high-strength low-shrinkage nylon material for 3D printing and its preparation method

A 3D printing, high-strength technology, applied in the field of 3D printing materials, can solve the problems of poor printing effect and poor mechanical properties, and achieve the effect of low shrinkage, high mechanical properties, and excellent physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

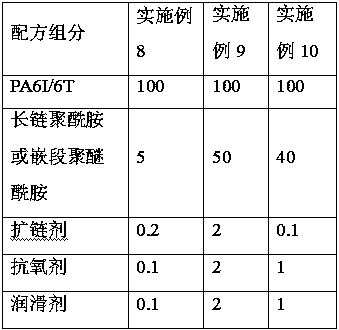

Examples

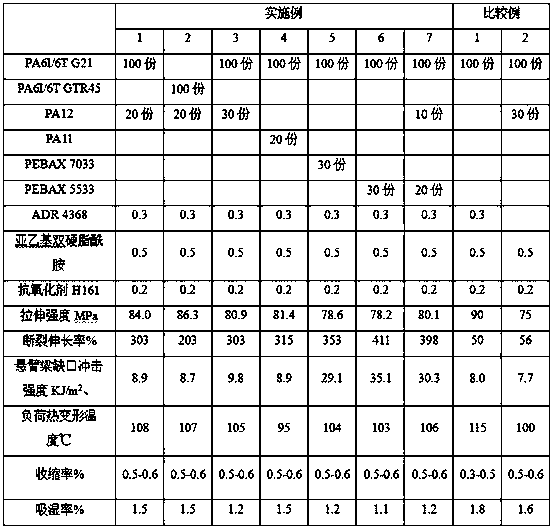

Embodiment 1

[0033] 100 parts of dried PA6I / 6T (specifically, G21 of Swiss EMS company), 20 parts of PA12 (specifically, of Swiss EMS company's L20W20), 0.5 parts of ethylene bisstearamide, 0.3 parts of chain extender / compatible agent (specifically ADR4368 from BASF, Germany), 0.2 parts of antioxidant H161, melt-blended, extruded and granulated at 200-245°C. The nylon modified material obtained above was dried for 4 hours in a dehumidification drying oven, the temperature of the dehumidification drying oven was 90°C, and the dew point temperature was -40°C. Afterwards, the dried resin composition is added to the FDM 3D printing consumable extruder, and the extrusion temperature is 235-245°C. Control the water temperature, extrusion volume and traction rate, and control the diameter of the consumables to be 1.75±0.03mm respectively to obtain high-strength FDM 3D nylon printing consumables. According to the standard test material, the tensile strength is 84.0MPa, the elongation at break is ...

Embodiment 2

[0035]100 parts of dried PA6I / 6T (specifically GTR45 from Swiss EMS), 20 parts of PA12 (specifically L20W20 from Swiss EMS), 0.5 parts of ethylenebisstearamide, 0.3 parts of chain extender / compatible Agent ADR 4368, 0.2 parts of antioxidant H161, melt blending extrusion granulation under the condition of 200-245 ℃. The nylon modified material obtained above was dried for 4 hours in a dehumidification drying oven, the temperature of the dehumidification drying oven was 90°C, and the dew point temperature was -40°C. Afterwards, the dried resin composition is added to the FDM 3D printing consumable extruder, and the extrusion temperature is 235-245°C. Control the water temperature, extrusion volume and traction rate, and control the diameter of the consumables to be 1.75±0.03mm respectively to obtain high-strength FDM 3D nylon printing consumables. According to the standard test material, the tensile strength is 86.3MPa, the elongation at break is 203%, and the notched impact st...

Embodiment 3

[0037] 100 parts of dried PA6I / 6T (specifically, G21 of Swiss EMS company), 30 parts of PA12 (specifically, of Swiss EMS company's L20W20), 0.5 parts of ethylene bisstearamide, 0.3 parts of chain extender / compatible Agent ADR 4368, 0.2 parts of antioxidant H161, melt blending extrusion granulation under the condition of 200-245 ℃. The nylon modified material obtained above was dried for 4 hours in a dehumidification drying oven, the temperature of the dehumidification drying oven was 90°C, and the dew point temperature was -40°C. Afterwards, the dried resin composition is added to the FDM 3D printing consumable extruder, and the extrusion temperature is 235-245°C. Control the water temperature, extrusion volume and traction rate, and control the diameter of the consumables to be 1.75±0.03mm respectively to obtain high-strength FDM 3D nylon printing consumables. According to the standard test material, the tensile strength is 80.9MPa, the elongation at break is 303%, and the n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com