Preparation method for nano copper oxide super-hydrophobic coating

A technology of super-hydrophobic coating and nano-copper oxide, which is applied in the field of materials science, can solve the problems of high cost of femtosecond laser equipment, the limitation of the blade size of millennium taro, and the complicated preparation method of special polymers, and achieve low cost and anti-icing High ability and strong water repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

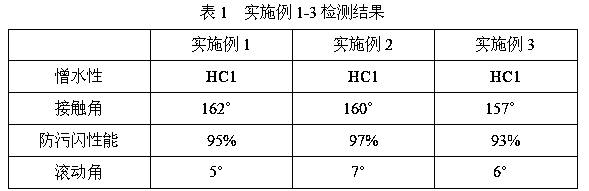

Embodiment 1

[0020] a. Surface modification of copper oxide nanoparticles

[0021] Fully dissolve the copper oxide nanoparticle raw material with a particle size of 50nm in ethanol solution to a mass concentration of 10%, add n-octyl mercaptan to it and mix thoroughly to obtain a suspension. The mass fraction of n-octyl mercaptan in ethanol is 1%; the suspension was reacted for 24 hours under sufficient stirring, then dried, and ground to obtain modified copper oxide nanoparticles;

[0022] b. Preparation of superhydrophobic coatings

[0023] Fully dissolve the modified copper oxide nanoparticles obtained in step a in the isopropanol solution to a mass fraction of 10%, and ultrasonically stir for 10 minutes to obtain solution a; fully dissolve the silicone rubber in the isopropanol solution to a mass fraction of 5% %, ultrasonically stirred for 10 minutes to obtain solution b; before using the coating, mix solutions a and b at a ratio of 1:1 to prepare a superhydrophobic coating.

[0024...

Embodiment 2

[0026] a. Surface modification of copper oxide nanoparticles

[0027] Fully dissolve copper oxide nanoparticles with a particle size of 40nm in an ethanol solution to a mass concentration of 15%, add n-octyl mercaptan to it and mix thoroughly to obtain a suspension, the mass fraction of n-octyl mercaptan in ethanol is 1.5 %; The suspension was reacted for 36 hours under sufficient stirring, then dried, and ground to obtain modified copper oxide nanoparticles;

[0028] b. Preparation of superhydrophobic coatings

[0029] Fully dissolve the modified copper oxide nanoparticles obtained in step a in the isopropanol solution to a mass fraction of 15%, and ultrasonically stir for 15 minutes to obtain solution a; fully dissolve the silicone rubber in the isopropanol solution to a mass fraction of 10% %, ultrasonically stirred for 15 minutes to obtain solution b; before using the coating, mix solutions a and b at a ratio of 1.5:1 to prepare a superhydrophobic coating.

[0030] The s...

Embodiment 3

[0032] a. Surface modification of copper oxide nanoparticles

[0033] Fully dissolve copper oxide nanoparticles with a particle size of 200nm in ethanol solution to a mass concentration of 5%, add n-octyl mercaptan to it and mix thoroughly to obtain a suspension, the mass fraction of n-octyl mercaptan in ethanol is 0.5 %; The suspension was reacted for 12 hours under the situation of sufficient stirring, then dried, and ground to obtain modified copper oxide nanoparticles;

[0034] b. Preparation of superhydrophobic coatings

[0035] Fully dissolve the modified copper oxide nanoparticles obtained in step a in the isopropanol solution to a mass fraction of 5%, and ultrasonically stir for 20 minutes to obtain solution a; fully dissolve the silicone rubber in the isopropanol solution to a mass fraction of 5% %, ultrasonically stirred for 7 minutes to obtain solution b; before using the coating, mix solutions a and b at a ratio of 1:1 to prepare a superhydrophobic coating.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com