Primer for bonding of addition type silicone rubber and dry type transformer material

A technology of primer and silane coupling agent, which is applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problem of inapplicable bonding between addition-type silicone rubber and dry-type transformers, and achieve enhanced Adhesive effect, effect of promoting hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

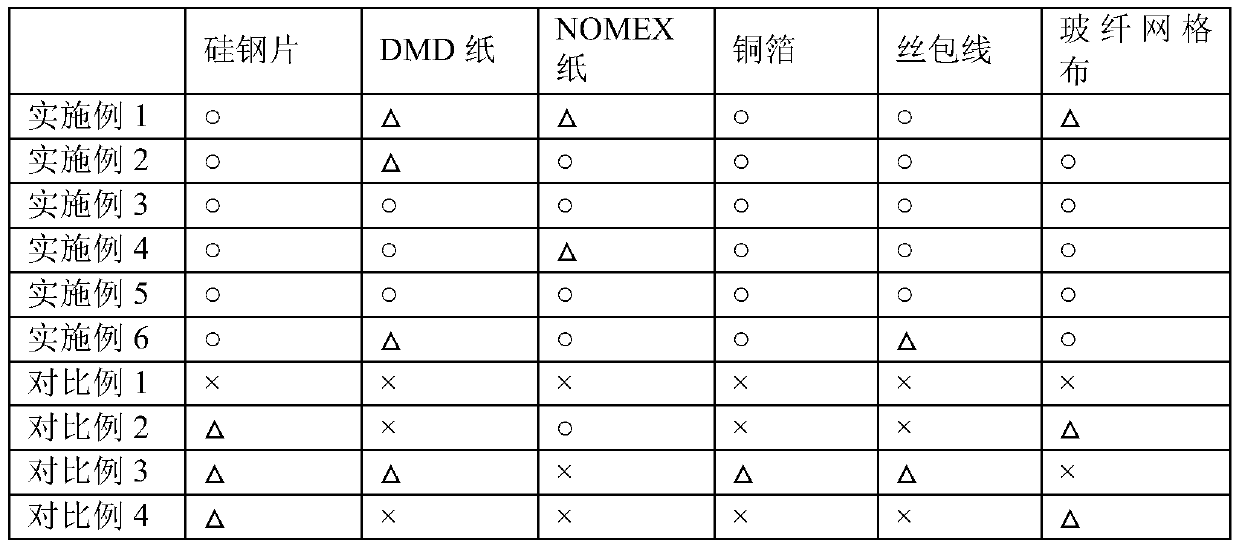

Examples

Embodiment 1

[0049] Mix and stir 8 parts by mass of silicone resin and 100 parts by mass of ethanol at room temperature. After the silicone resin is completely dissolved, add 7 parts by mass of vinyltrimethoxysilane, 3 parts by mass of (3-methacryloyloxypropane base) trimethoxysilane, 5 parts by mass of (3-glycidoxypropyl) trimethoxysilane and 25 parts by mass of ethyl orthosilicate, mix evenly to obtain the primer. Wherein, the silicone resin structure is as follows:

[0050] [(CH 3 ) 3 SiO 1 / 2 ] 5 [H(CH 3 ) 2 SiO 1 / 2 ] 10 [HOSiO 3 / 2 ] 5 [SiO 4 / 2 ] 20

[0051] Apply the primer above to the surface of the dry-type transformer material, let it dry at room temperature for half an hour, then apply and mold silicone rubber (Dow Corning HV1551 / 55P), and cure at 150°C for half an hour. After cooling, tear off the silicone layer by hand to observe its peeling state on the surface of the substrate.

Embodiment 2

[0053] Mix and stir 20 parts by mass of silicone resin and 100 parts by mass of ethanol at room temperature. After the silicone resin is completely dissolved, add 3 parts by mass of vinyltrimethoxysilane, 8 parts by mass of (3-acryloyloxypropyl) Trimethoxysilane, 6 parts by mass of (3-glycidoxypropyl) triethoxysilane, 35 parts by mass of ethyl orthosilicate and 0.5 part by mass of glacial acetic acid were mixed uniformly to obtain the primer.

[0054] Wherein, the silicone resin structure is as follows:

[0055] [(CH 3 ) 3 SiO 1 / 2 ] 3 [H(CH 3 ) 2 SiO 1 / 2 ] 15 [HOSiO 3 / 2 ] 2 [SiO 4 / 2 ] 25

[0056] Apply the primer above to the surface of the dry-type transformer material, let it dry at room temperature for half an hour, then apply and mold silicone rubber (Dow Corning HV1551 / 55P), and cure at 150°C for half an hour. After cooling, tear off the silicone layer by hand to observe its peeling state on the surface of the substrate.

Embodiment 3

[0058] Mix and stir 13 parts by mass of silicone resin and 100 parts by mass of isopropanol at room temperature. After the silicone resin is completely dissolved, add 5 parts by mass of vinyltriethoxysilane, 6 parts by mass of (3-methylpropene Acyloxypropyl) trimethoxysilane, 4 parts by mass of (3-glycidoxypropyl) trimethoxysilane, 30 parts by mass of propyl orthosilicate and glacial acetic acid of 0.2 parts by mass, mix evenly to get Primer.

[0059] Wherein, the silicone resin structure is as follows:

[0060] [H(CH 3 ) 2 SiO 1 / 2 ] 15 [HOSiO 3 / 2 ] 4 [SiO 4 / 2 ] 30

[0061] Apply the primer above to the surface of the dry-type transformer material, let it dry at room temperature for half an hour, then apply and mold silicone rubber (Dow Corning HV1551 / 55P), and cure at 150°C for half an hour. After cooling, tear off the silicone layer by hand to observe its peeling state on the surface of the substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com