Slanted-bottom kettle type solar distiller

A distillation device and solar energy technology, applied in the field of solar energy distillation, can solve problems such as aggravating environmental pollution, causing greenhouse effect, endangering human living environment, etc., and achieve the effects of reliable operation, improved utilization rate, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

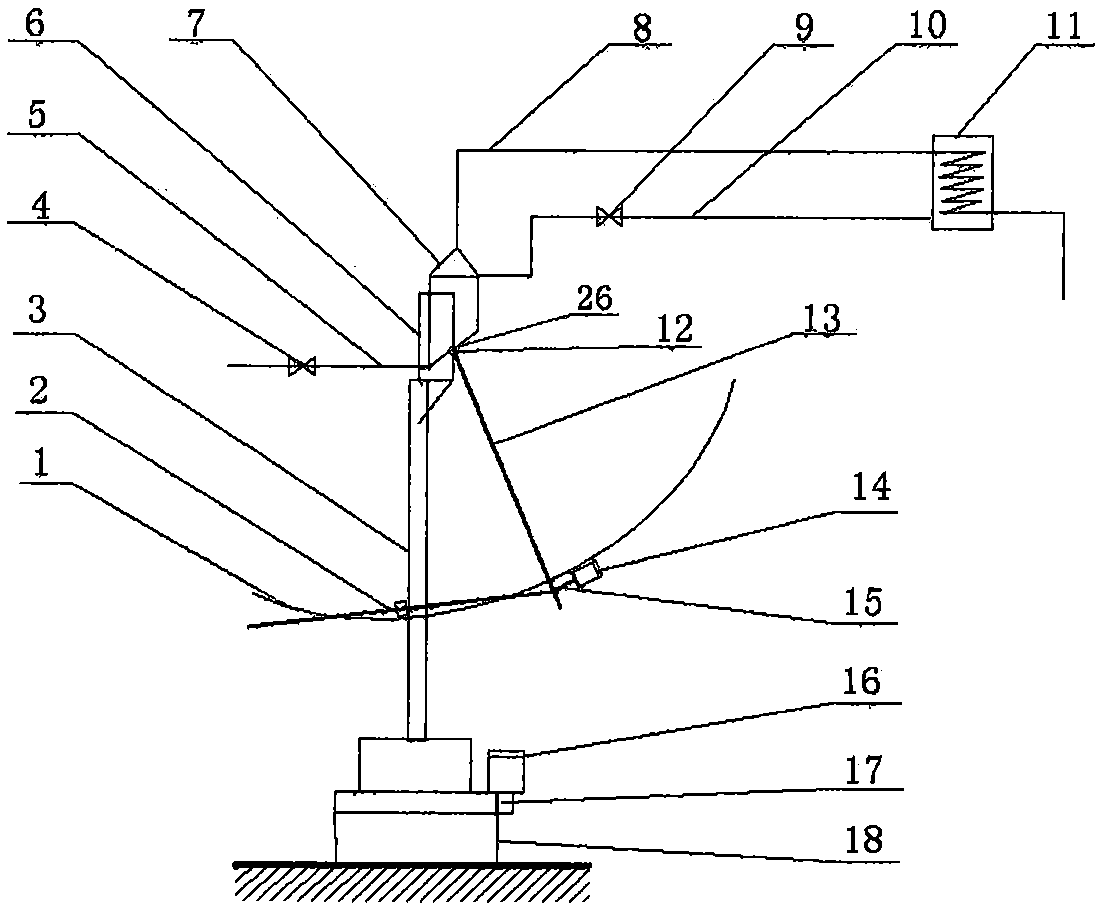

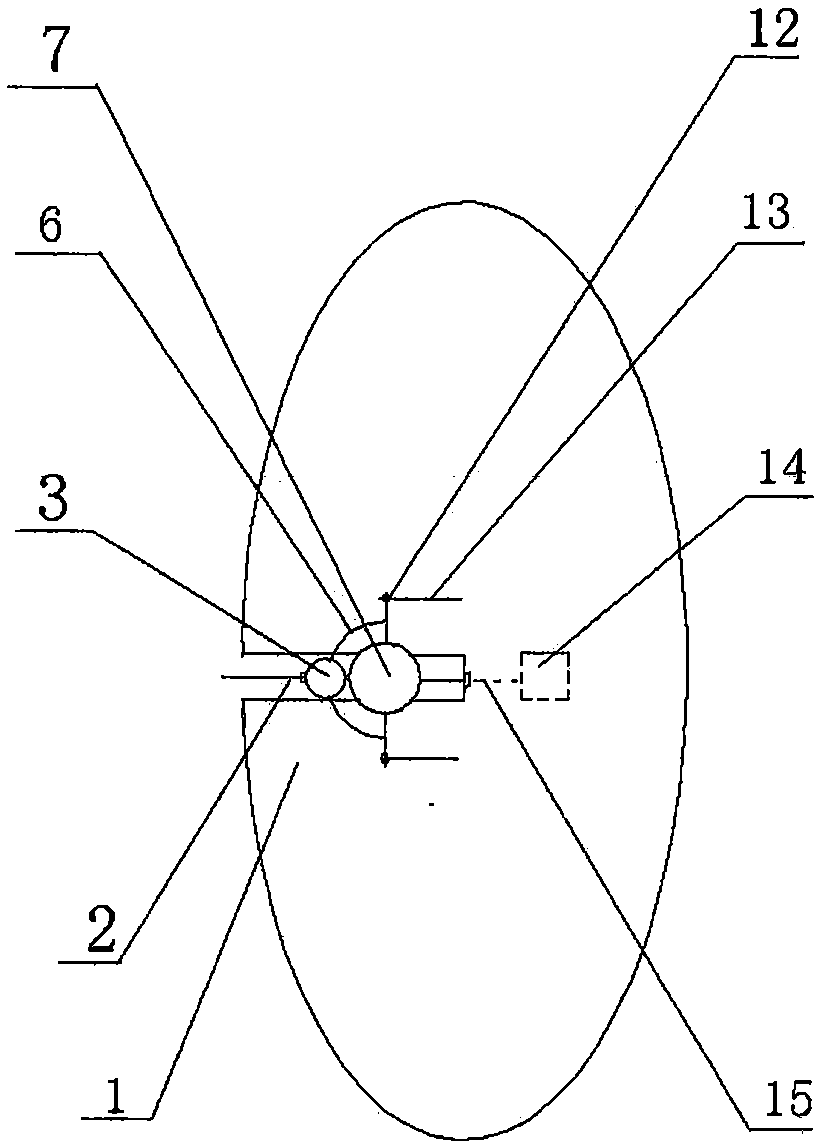

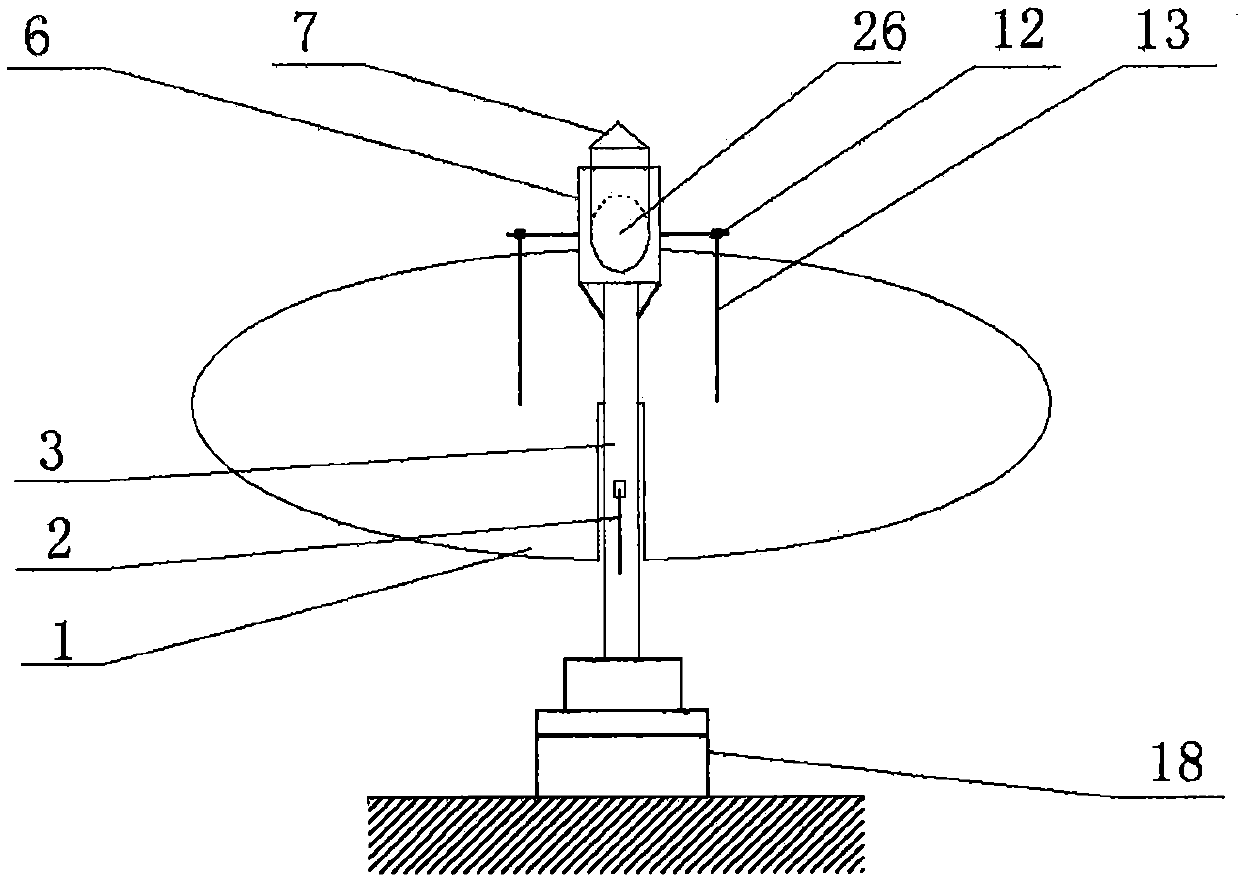

[0019] exist figure 1 Among them, the parabolic solar heat collector 1 focuses the solar energy on the elliptical heat-absorbing surface 26 of the inclined bottom kettle 7, and heats the wine mash in the kettle to boiling to obtain alcohol gas, which passes through the steam pipe 8 to the condenser (pre- Heater) 11, in the condenser (preheater) through heat exchange condensation to obtain liquor liquid, the alcohol gas preheats the wine mash during the heat exchange process of the condenser to improve the utilization rate of solar energy.

[0020] During the distillation process, when the alcohol content of the distillate is lower than 3% (v / v), the distillation is stopped, the discharge valve 4 is opened, the distiller's grains are discharged through the discharge pipe 5, and the discharge valve 4 is closed after the discharge is completed. , open the feed valve 9, add the preheated wine mash in the inclined bottom kettle through the feed pipe 10, and close the feed valve 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com