Yarrowia lipolytica and method for producing gamma-decalactone by using same

A technology of Yarrowia lipolytica and decalactone, which is applied in the direction of microbial-based methods, biochemical equipment and methods, and bulk chemical production, to achieve the effects of increasing yield, good economic value and application potential, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

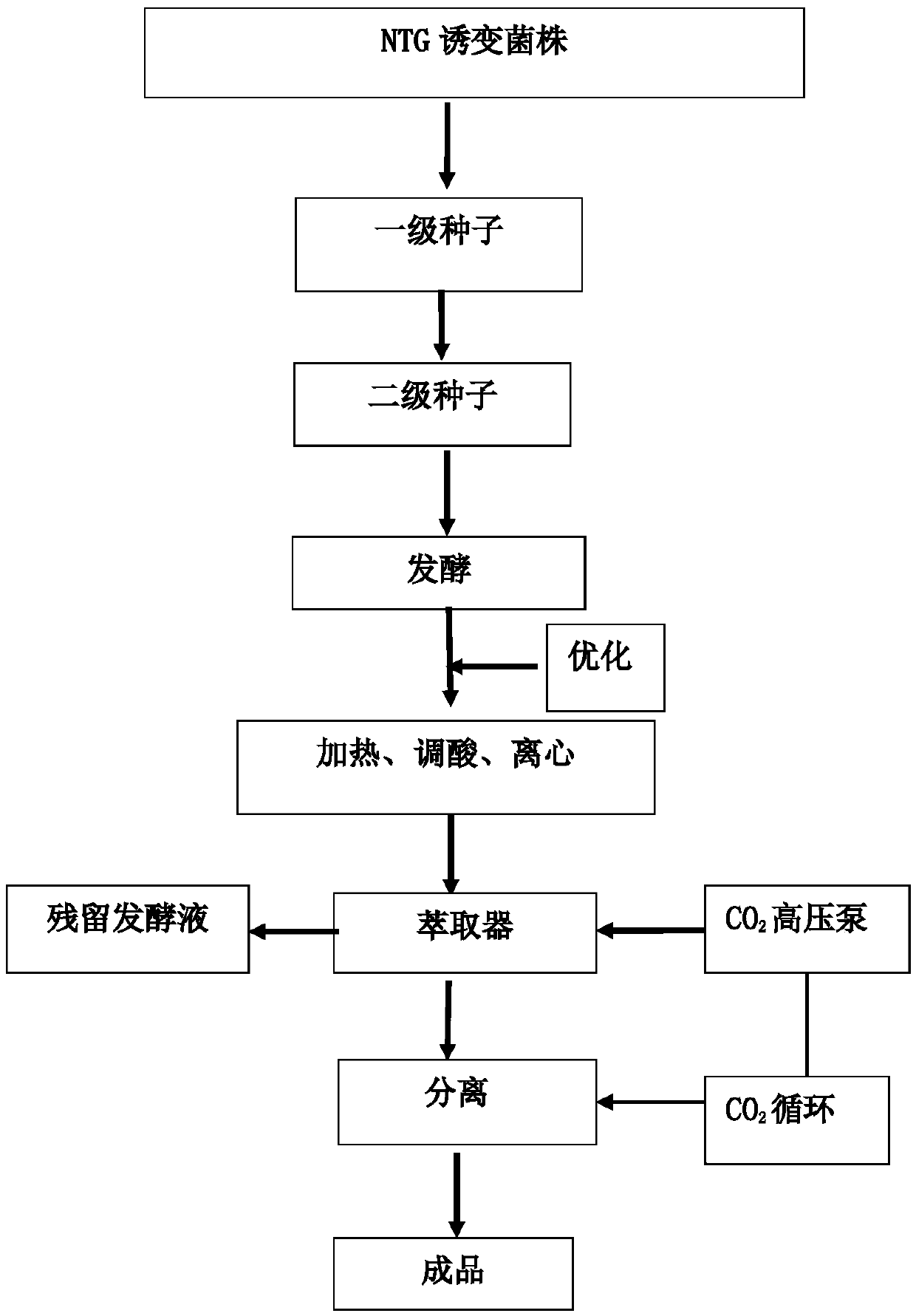

[0036] The method of the present invention comprises the following steps:

[0037] 1. Fermentation strain: Yarrowia Lipolytica (Yarrowia Lipolytica) C85 screened by nitrosoguanidine (NTG) mutagenesis # .

[0038] Nitrosoguanidine (NTG) mutagenesis: Centrifuge the seed medium in the logarithmic growth phase of the medium (6000r / min5min), wash with 20mL phosphate buffer each time, centrifuge twice, combine, draw 20ml of bacterial suspension into a In the small Erlenmeyer flask with glass beads wrapped in a black bag, add 0.6ml NTG (preparation method: add 2.5mg NTG, distilled water to 10ml, final concentration is 0.25mg / ml). The colonies with better growth were selected and subjected to shake flask fermentation experiments, and were repeatedly screened by NTG treatment to obtain C85 # , after fermentation, the lactone output can reach more than 8.7g / L.

[0039] 2. Medium:

[0040] (1) Slant medium: wort slant (recipe: malt extract powder 90-120g / L, yeast powder 5-10g / L, agar...

Embodiment 2

[0051] Take the primary seeds in a 500mL Erlenmeyer flask, fill with 150-200mL seed culture medium, inoculum size 10%-15%, culture on a shaker at 25°C, 175r / min for 48h, initial pH 6.0, to obtain secondary seeds.

[0052] Inoculation of large-volume fermentation culture in a 50L fermenter: transfer the secondary seeds into a 50L fermenter (with 30L sterilized fermentation medium inside) according to the inoculum amount of 2%, and use 5% castor methanolic acid methyl ester respectively At 64h, 76h, 92h, and 102h, feed was fed in batches, adding 3% glucose and 2% methyl ricinoleate in a mass-volume ratio to the fermentation medium. The fermentation temperature was adjusted to 27° C. and the fermentation time was 288 hours. The measured concentration of γ-decalactone was 87.53%, the yield was 14.52 g / L, and the conversion rate was 49.34%.

[0053] Among them, the seed medium contains: glucose 15g / L, yeast extract 2.5g / L, peptone 3.5g / L, magnesium sulfate 2.4g / L, potassium dihydro...

Embodiment 3

[0056] Take the primary seeds in a 500mL Erlenmeyer flask, fill with 150-200mL seed culture medium, inoculum size 10%-15%, culture on a shaker at 25°C, 175r / min for 48h, initial pH 6.0, to obtain secondary seeds.

[0057] Inoculation of large-volume fermentation culture in a 50L fermenter: transfer the secondary seeds into a 50L fermenter (with 30L sterilized fermentation medium inside) according to the inoculum amount of 2%, and use 5% castor methanolic acid methyl ester respectively At 64h, 76h, 92h, and 102h, feed was fed in batches, adding 4% glucose and 7% methyl ricinoleate in a mass-volume ratio to the fermentation medium. The fermentation temperature was adjusted to 27° C. and the fermentation time was 288 hours. The measured concentration of γ-decalactone was 85.1%, the yield was 14.9 g / L, and the conversion rate was 49.2%. Among them, the seed medium contains: glucose 18g / L, yeast extract 7.5g / L, peptone 7.5g / L, magnesium sulfate 5g / L, potassium dihydrogen phosphate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com