Amino/carboxyl composite self-assembly monomolecular film surface, preparation method thereof and application thereof

A self-assembly, molecular film technology, applied in the direction of metal material coating process, etc., to avoid acid-base reaction and improve the preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

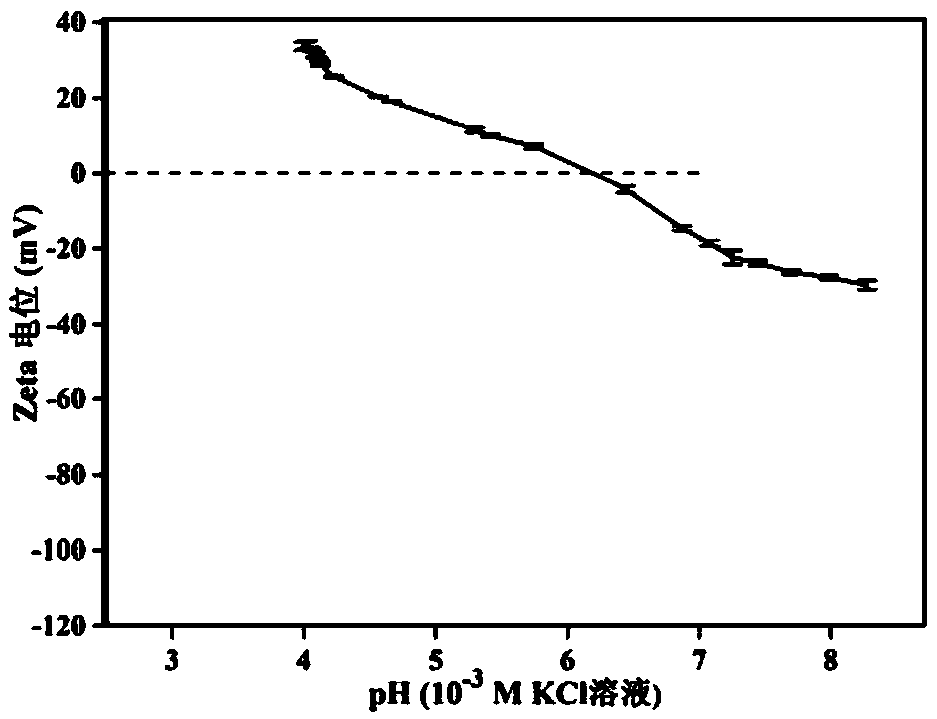

[0031] "Piranha" solution (H 2 O 2 :H 2 SO 4 =3:7(v / v)) Soak the gold substrate (gold flakes) for 15min. During the soaking process, the cleaning solution completely covers the gold flakes. At the beginning, a large number of bubbles are generated on the surface of the gold until no more bubbles are generated. After alternately washing with pure water for three times, dry it with nitrogen to obtain a clean gold substrate; immediately immerse the clean gold substrate in a concentration of 10 -3 molL -1 mercapto-undecylamine hydrochloride (-NH 2 ) in the ethanol solution of thiol for 12 h; after the reaction was completed, the modified gold substrate was washed with anhydrous ethanol for three times, dried with nitrogen and air-sealed for use, to obtain a self-assembled monomolecular membrane surface chemically modified by amino groups (ie- NH 2 chemically modified SAMs).

Embodiment 2

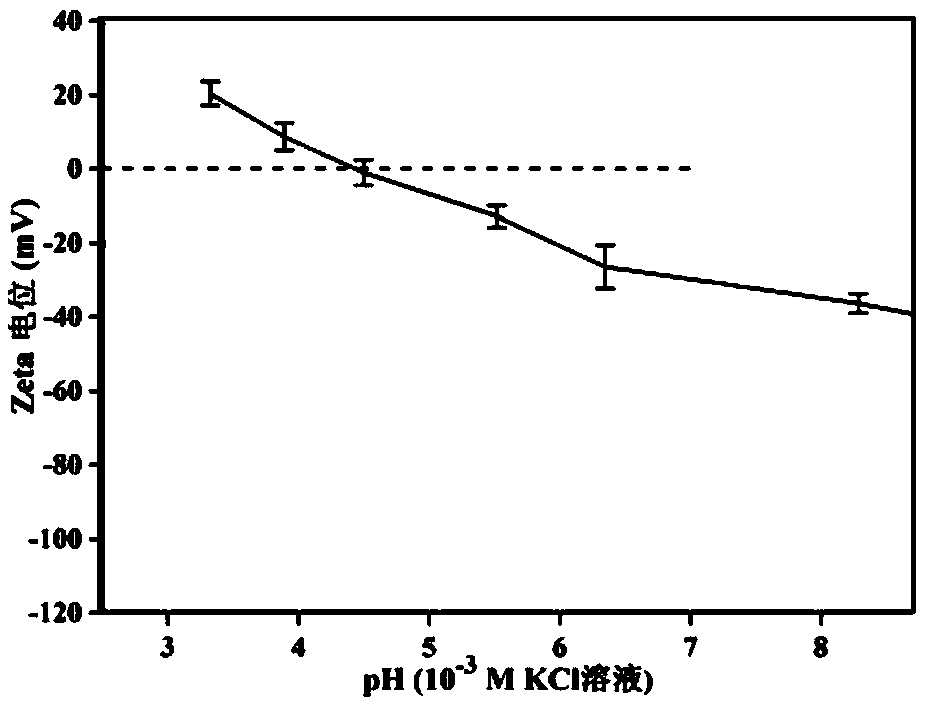

[0033] Load -NH in Example 1 2 The gold substrates of chemically modified SAMs were immersed in a concentration of 1 molL -1 bromoacetic acid (BrCH 2 COOH) and the concentration is 2molL -1 Acidification was carried out in the mixed solution of sodium hydroxide (NaOH), and the reaction time was controlled to 0.5h; the sample was taken out, washed and soaked in ultrapure water for 12h, the salt was absorbed, dried with nitrogen and air-sealed for later use, and the amino / carboxyl group composite self was obtained. Assemble molecular membrane surfaces.

Embodiment 3

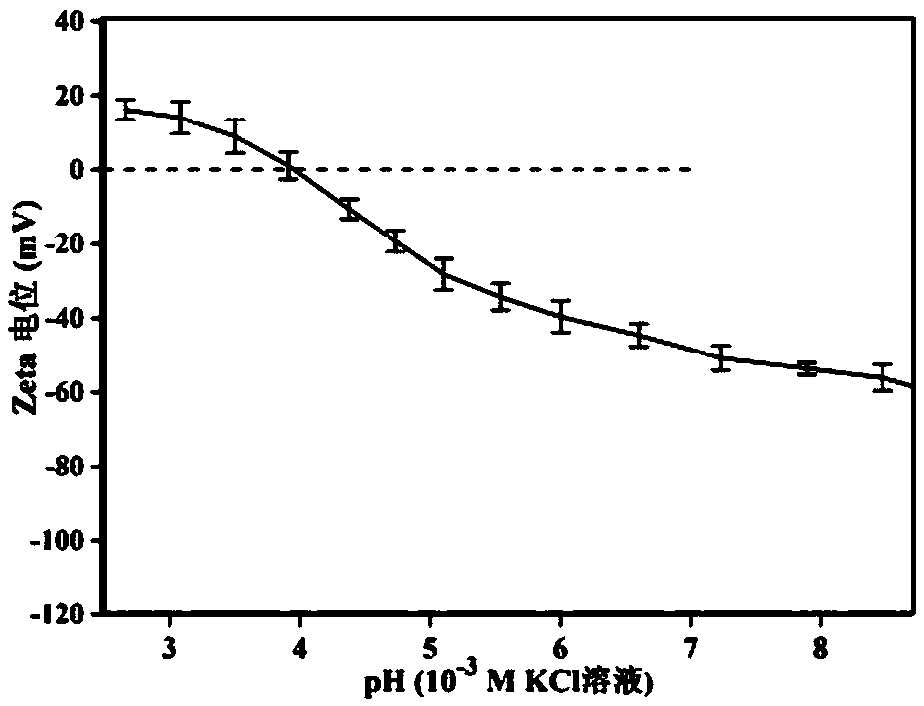

[0035] Load -NH in Example 1 2 The gold substrates of chemically modified SAMs were immersed in a concentration of 1 molL -1 bromoacetic acid (BrCH 2 COOH) and the concentration is 2molL -1 Acidification treatment was carried out in the mixed solution of sodium hydroxide (NaOH), and the reaction time was controlled for 2h; the sample was taken out, washed and soaked in ultrapure water for 12h, the salt was absorbed, dried with nitrogen and air-sealed for use, and the amino / carboxyl group composite self-assembly was obtained. molecular membrane surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com