Oral micro-effervescent granules and preparation method thereof

A technology of microbubbles and granules, applied in the field of oral micro-effervescent granules and their preparation, can solve the problems of affecting the absorption of functional substances, poor disintegration effect, and inability to fill the oral cavity, and achieves favorable absorption, wide disintegration range, and taste Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The present invention also provides a preparation method of the above-mentioned oral micro-effervescent granules, comprising the following steps:

[0058] Separately prepare acid granules and alkali granules;

[0059] mixing the acid granules and base granules;

[0060] Wherein, preparing the acid granules refers to mixing the components of the acid granules and then pulverizing and sieving or mixing them after pulverizing and sieving separately, and performing the first boiling granulation;

[0061] The preparation of the alkali granules means that the components of the alkali granules are mixed and then pulverized and sieved or separately pulverized and sieved and then mixed to perform the second boiling granulation.

[0062]In one example, the process conditions for the first boiling granulation include: material temperature 30°C-50°C, fan frequency 15Hz-30Hz, liquid supply speed 8rpm-20rpm, atomization pressure 0.2Mpa-0.5Mpa;

[0063] The technical conditions of t...

Embodiment 1~3

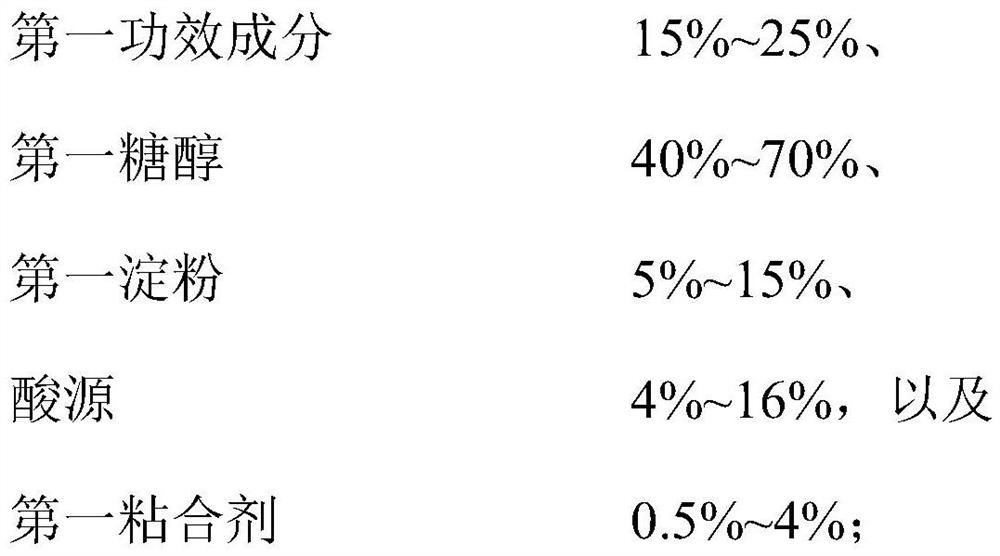

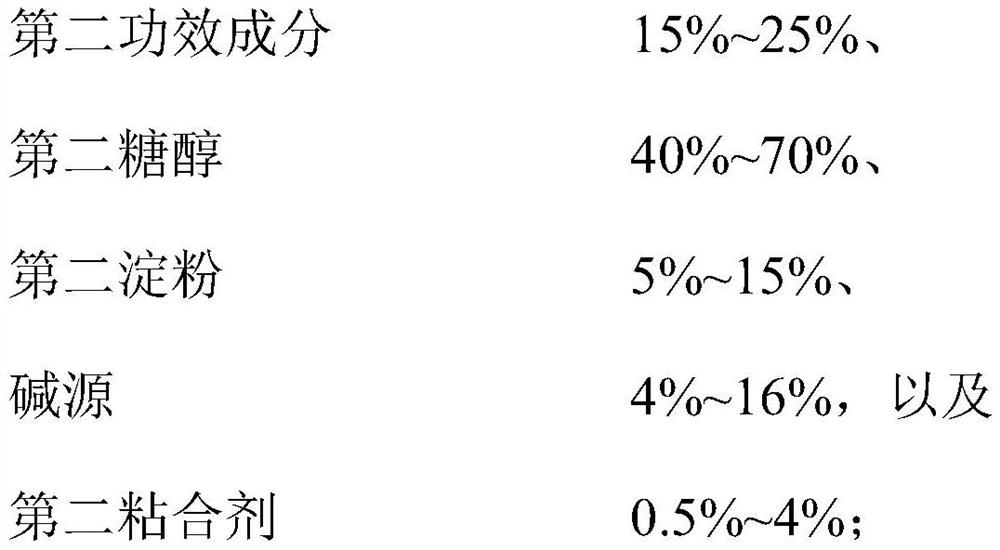

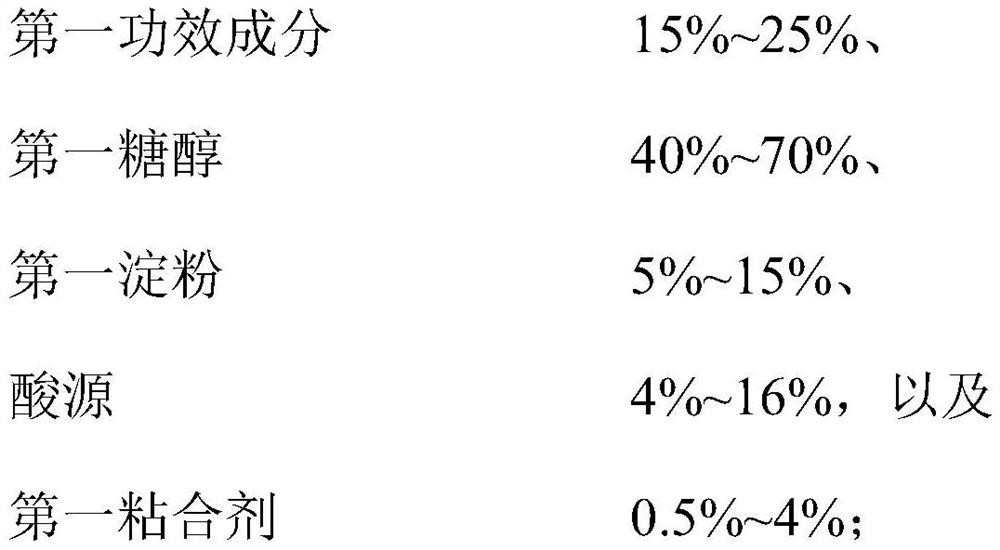

[0067] The present embodiment provides 3 kinds of oral micro-effervescent granules, the formula of which is shown in Table 1 (mass percentage):

[0068] Table 1

[0069]

[0070] The preparation method of above-mentioned oral micro-effervescent granule is as follows:

[0071] (1) Pulverize nutrients, sugar alcohols, fruit powder, sweetener, starch and acid source, pass through an 80-mesh sieve, and mix for later use;

[0072] (2) Preparation of adhesive: with pure water As a solvent, the adhesive is prepared into an adhesive solution with a mass concentration of 1%, and natural pigments are added;

[0073] (3) Boiling granulation: mixing the materials in steps (1) and (2) for boiling granulation, the conditions are as follows: material temperature 40°C, fan frequency 20Hz, liquid supply speed 15rpm, atomization pressure 0.3Mpa; then 40 mesh sieve Whole grain; get acid grain;

[0074] (4) Steps (1) to (3) prepare alkali granules in the same way;

[0075] (5) A gravity-f...

Embodiment 4-8

[0077] Granulation with different starches or dextrins. The formulations of oral micro-effervescent granules provided in Examples 4-8 are the same as those in Example 1, except that the starch used is different, which are maltodextrin, corn starch, resistant dextrin, modified starch and pregelatinized starch.

[0078] The formula is specifically shown in the following table 2 (mass percentage):

[0079] Table 2

[0080]

[0081]

[0082] The preparation method of above-mentioned oral micro-effervescent granule is as follows:

[0083] (1) Pulverize nutrients, sugar alcohols, fruit powder, sweetener, starch and acid source, pass through an 80-mesh sieve, and mix for later use;

[0084] (2) Preparation of adhesive: with pure water As a solvent, the adhesive is prepared into an adhesive solution with a mass concentration of 1%, and natural pigments are added;

[0085] (3) Boiling granulation: mixing the materials in steps (1) and (2) for boiling granulation, the conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com