Jagged annular needleless static spinning device and application method thereof

An electrospinning, needle-free technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of non-oriented nanofiber product structure, non-automatic solution supply, and low nanofiber output. Achieve the effect of solving the uncontrollable structure of nanofibers, realizing industrialized preparation, and solving the problem of easy volatilization of solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

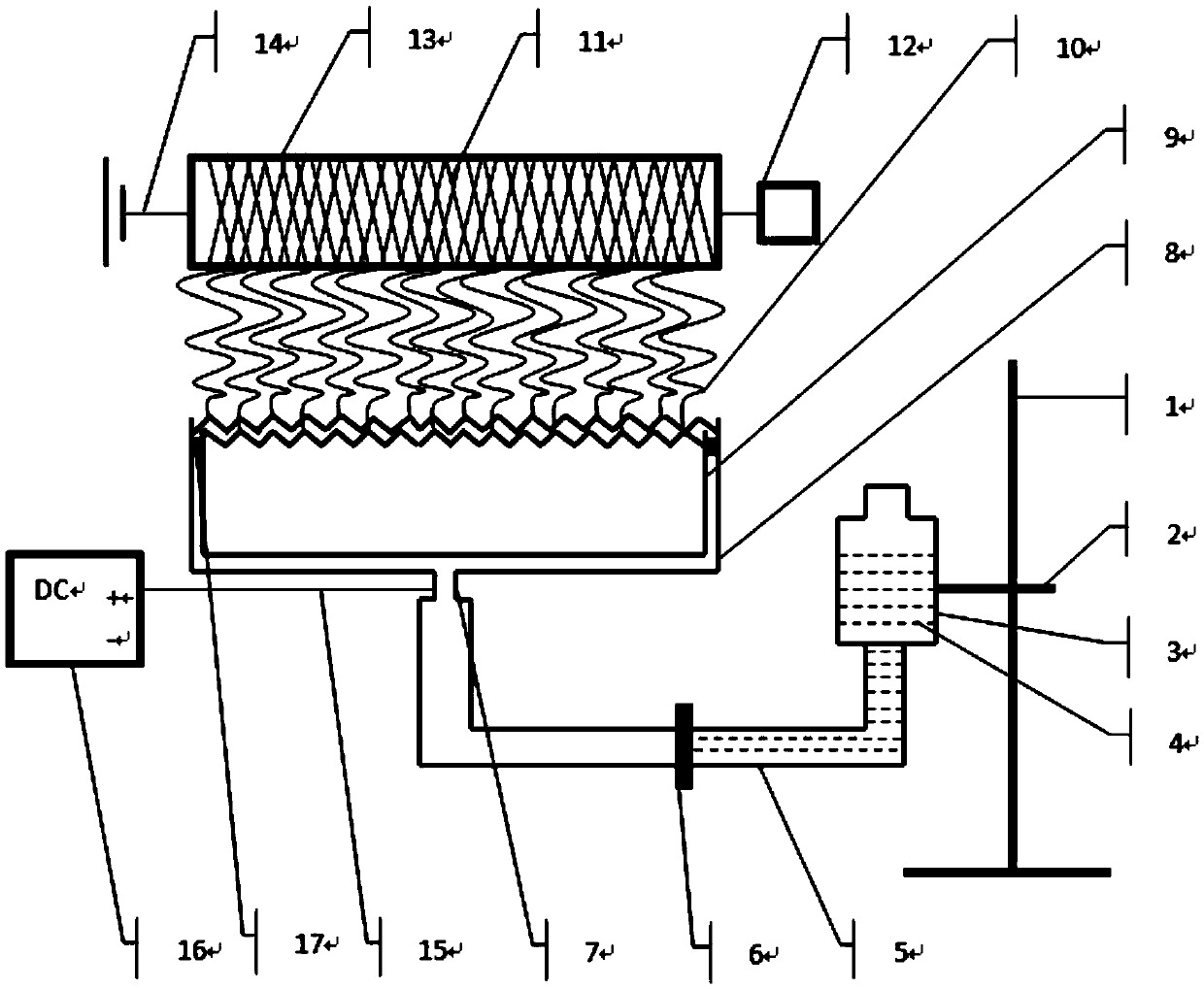

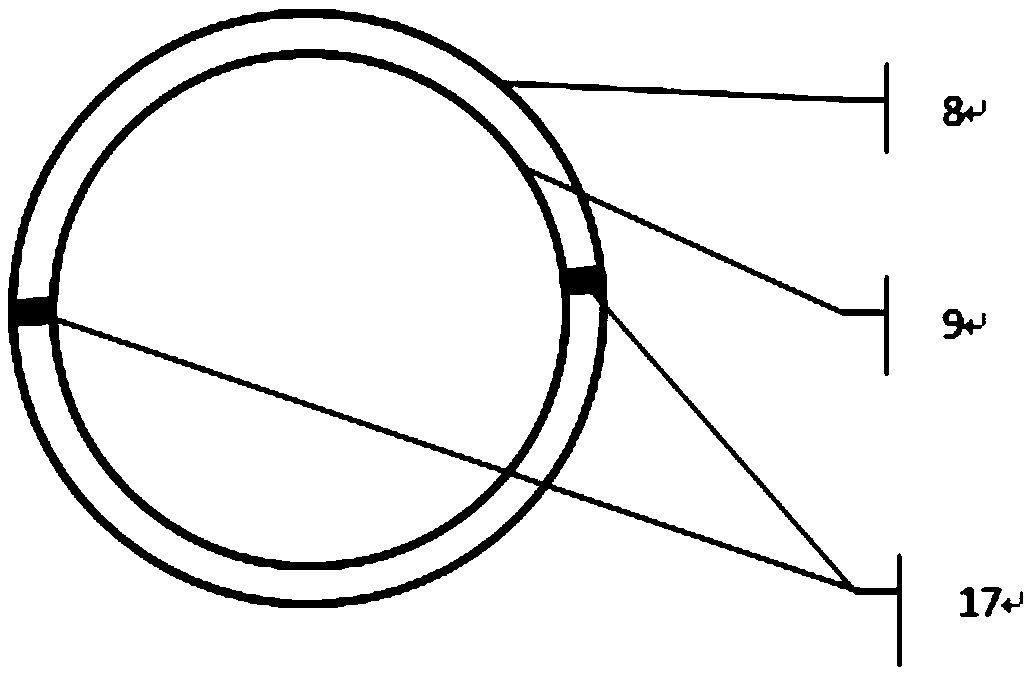

[0043] Next, nanofibers are prepared by using a polymer solution prepared from polyacrylonitrile (PAN) and dimethylformamide (DMF). The mass fraction of the prepared PAN polymer solution is 10%. Connect the liquid storage bottle 3 and the central copper metal tube 7 at the bottom of the outer ring liquid tank with the catheter 5, turn off the middle switch 6 of the catheter, and then fill the liquid storage bottle 3 with an appropriate amount of prepared PAN polymer solution 4 ; Turn on the middle switch 6 of the catheter, and the polymer solution 4 slowly flows into the annular slit formed by the zigzag outer ring liquid tank 8 and the inner ring liquid tank 9 through the catheter tube; height, so that the polymer solution overflows in the annular slit formed by the zigzag outer ring liquid tank 8 and the inner ring liquid tank 9, it is advisable to ensure that the liquid level overflows between the annular slits but does not flow out; The metal drum 13 is connected with the...

Embodiment 2

[0045] Connect the liquid storage bottle 3 and the central copper metal tube 7 at the bottom of the outer ring liquid tank with the catheter tube 5, close the middle switch 6 of the catheter tube, and then fill the liquid storage bottle 3 with an appropriate amount of PAN with a mass fraction of 10%. Polymer solution 4; open the middle switch 6 of the catheter, and the polymer solution 4 slowly flows into the annular slit formed by the zigzag outer ring liquid tank 8 and the inner ring liquid tank 9 through the catheter tube; adjust the storage through the clip 2 The height of the liquid bottle 3 makes the polymer solution overflow in the annular slit formed by the zigzag outer ring liquid tank 8 and the inner ring liquid tank 9, ensuring that the liquid level overflows between the annular slits but does not flow out It is advisable; connect the metal drum 13 with the ground wire 14, turn on the motor 12 connected to the metal drum 13, set the distance from the main shaft of th...

Embodiment 3

[0047] Connect the liquid storage bottle 3 and the central copper metal tube 7 at the bottom of the outer ring liquid tank with the catheter tube 5, close the middle switch 6 of the catheter tube, and then fill the liquid storage bottle 3 with an appropriate amount of PAN with a mass fraction of 10%. Polymer solution 4; open the middle switch 6 of the catheter, and the polymer solution 4 slowly flows into the annular slit formed by the zigzag outer ring liquid tank 8 and the inner ring liquid tank 9 through the catheter tube; adjust the storage through the clip 2 The height of the liquid bottle 3 makes the polymer solution overflow in the annular slit formed by the zigzag outer ring liquid tank 8 and the inner ring liquid tank 9, ensuring that the liquid level overflows between the annular slits but does not flow out It is advisable; connect the metal drum 13 with the ground wire 14, turn on the motor 12 connected to the metal drum 13, set the distance from the main shaft of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com