Laser illumination optical system combining diffraction optical element with laser

A diffractive optical element and laser lighting technology, which is applied in the field of optoelectronic communication, can solve problems such as unsatisfactory application fields, large size, and simple light field control method, and achieve high light intensity utilization efficiency, improved light utilization efficiency, and rich optical functions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

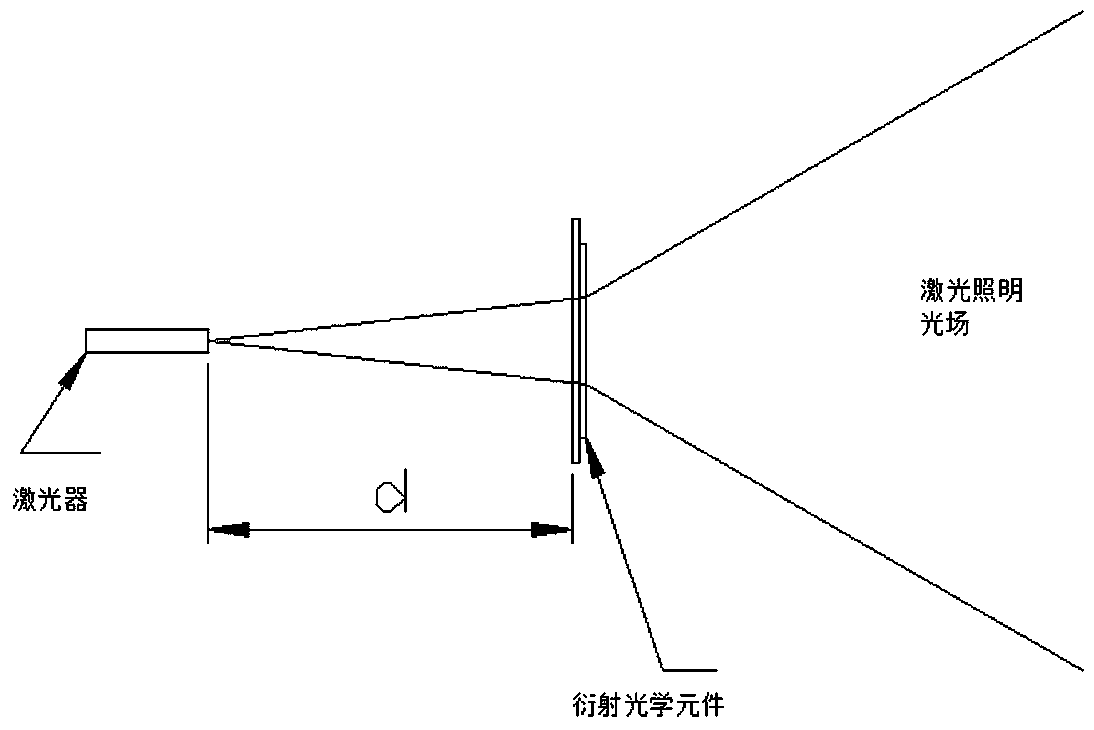

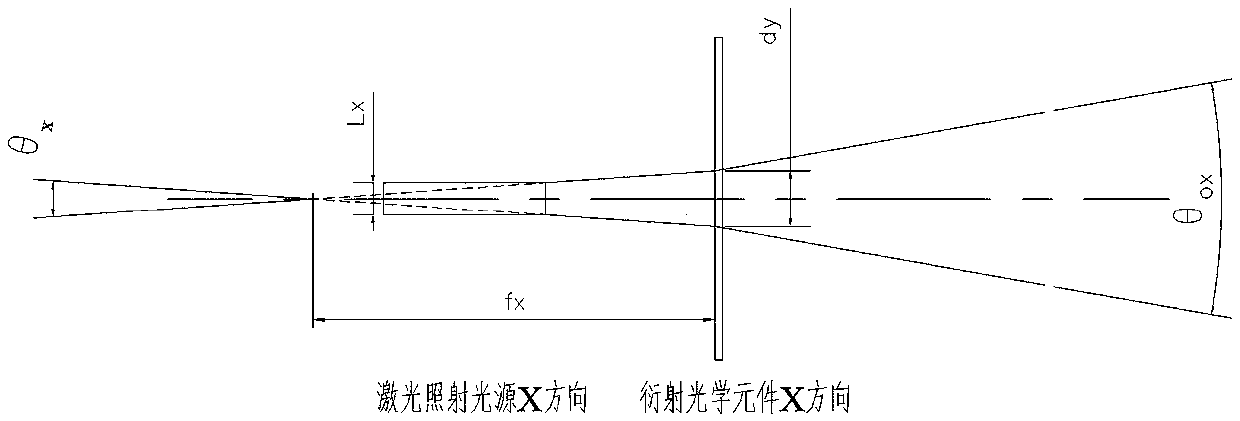

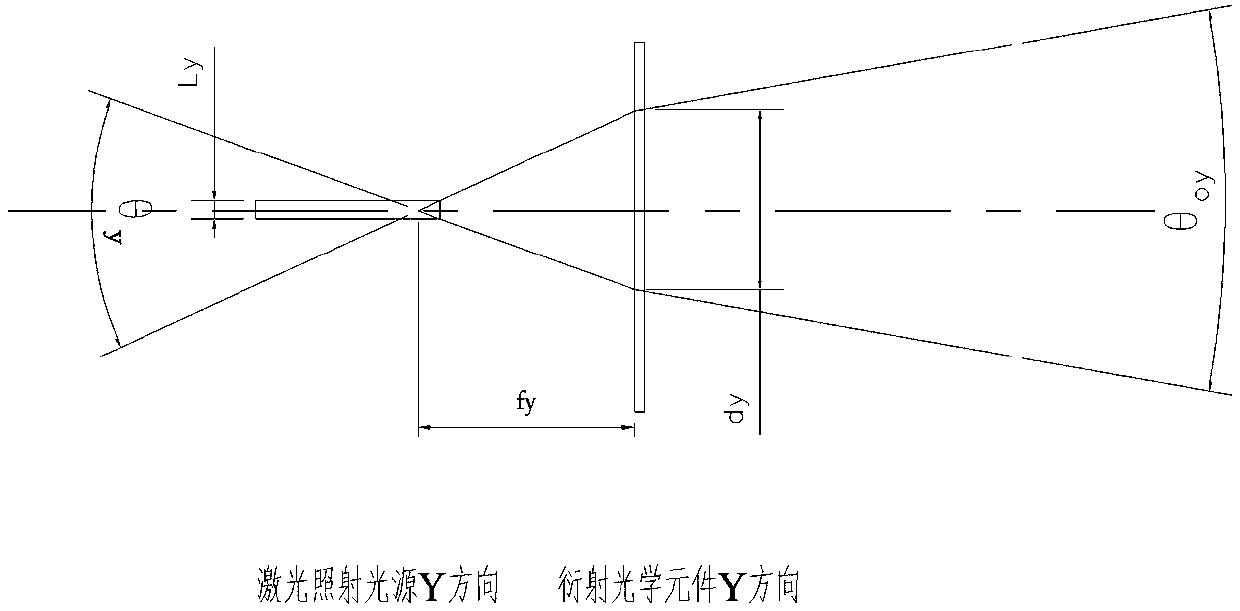

[0022] like figure 1 As shown, the function of the diffractive optical element is: the incident beam is a parallel or divergent laser beam, and the incident beam irradiates the diffractive optical element to realize an outgoing light field. The diffractive optical element is targeted according to the optical characteristics of the incident light field. Design, adjust the wavefront of the incident light field, and realize the Fourier transform from the incident light field to the required exit light field. The position of the laser light source and the diffractive optical element is fixed, and the divergence angle design of the required complex illumination light field can be realized only through the adjustment of one diffractive optical element. Cost, expanding the application fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com