Method for obtaining high-color-gamut white-light LED through red-light fluorescent powder

A technology of red phosphor powder and realization method, applied in the field of white light LED backlight, can solve the problems of low color gamut value of white light LED backlight source, difficult particle size control, poor color reproduction degree, etc., and achieves simple packaging process and high excitation efficiency , the effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

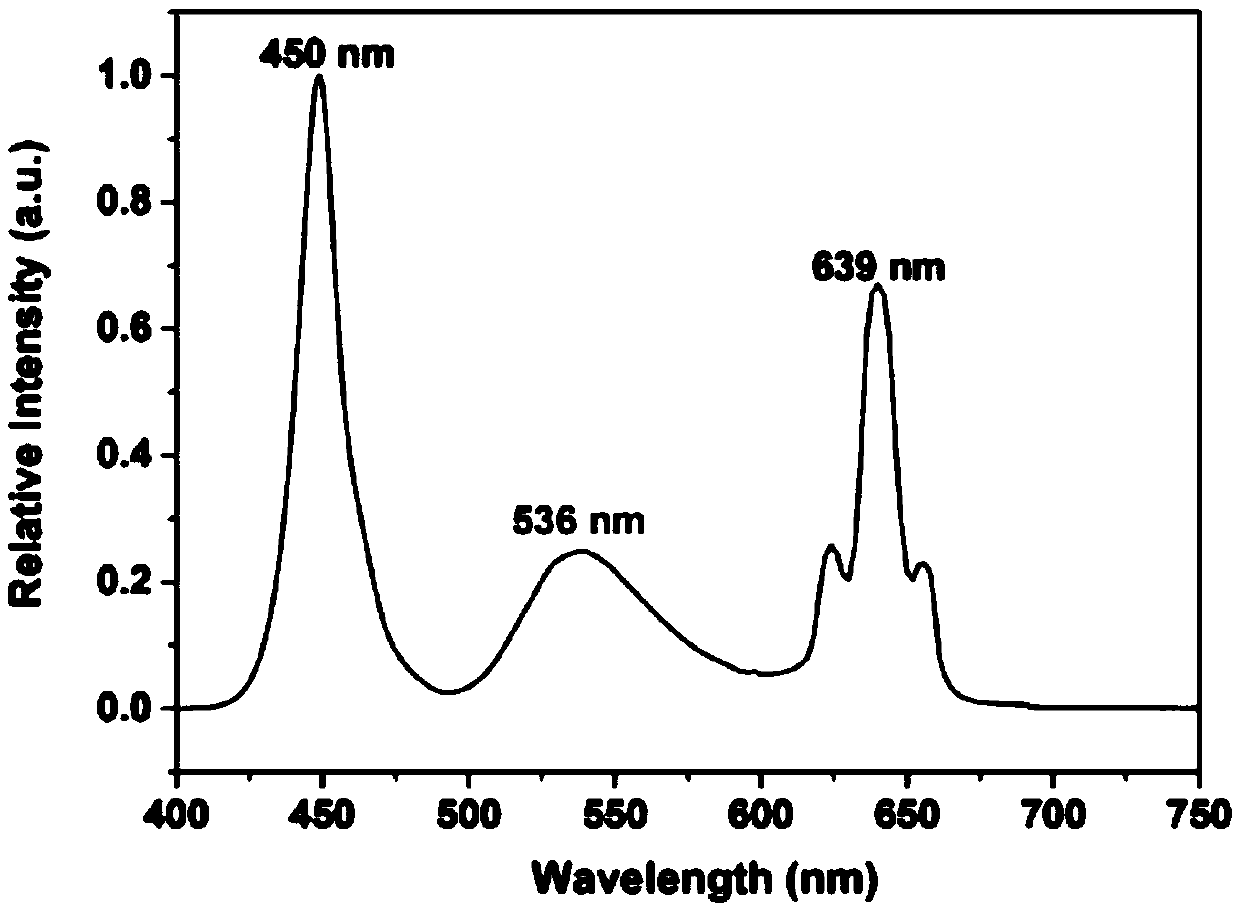

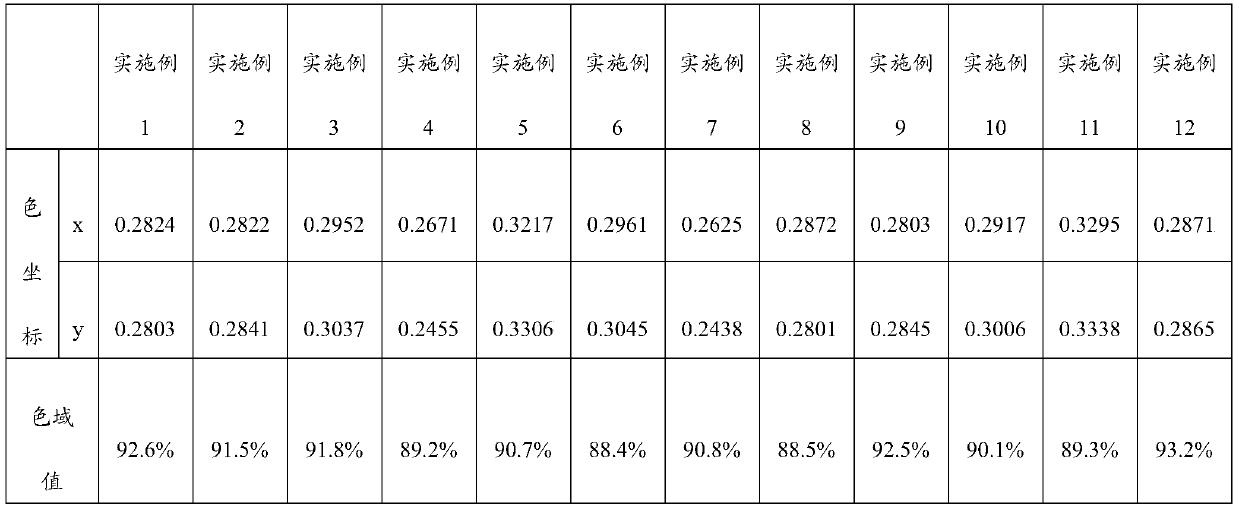

[0038] This embodiment provides a method using MASiO 4 :Eu 3+ A method for realizing a white light LED with a high color gamut of red phosphor powder, comprising the following steps:

[0039] 1) Weigh 5.40g of encapsulation glue A and 2.70g of encapsulation glue B according to the mass ratio of 2:1, and mix them evenly to obtain a mixed encapsulation glue. The encapsulation glue A and the encapsulation glue B are epoxy A type of encapsulation glue, the viscosity of the mixed encapsulation glue is 8000mPa·S, and the refractive index is 1.43;

[0040] 2) Weigh the fluorescent powder according to the emission wavelength of the chip: the chip is an ultraviolet chip, and the emission peak value is 350nm. According to the mass ratio of 1:1:2.5, weigh 1.53g of MASiO with a peak wavelength of 635nm 4 :Eu 3+ Red phosphor, 1.53g of silicate green phosphor with a peak wavelength of 544nm and 3.83g of aluminate blue phosphor with a peak wavelength of 480nm, the three phosphors were add...

Embodiment 2

[0044] This embodiment provides a method using MASiO 4 :Eu 3+ A method for realizing a white light LED with a high color gamut of red phosphor powder, comprising the following steps:

[0045] 1) According to the mass ratio of 3:1, weigh 7.20g of packaging glue A and 2.40g of packaging glue B, and mix them evenly to obtain a mixed packaging glue. The packaging glue A and the packaging glue B are silicone Class encapsulation glue, the viscosity of the mixed encapsulation glue is 600mPa·S, and the refractive index is 1.45;

[0046] 2) Weigh the fluorescent powder according to the emission wavelength of the chip: the chip is an ultraviolet chip, and the emission peak value is 365nm. According to the mass ratio of 4:1:5, weigh 1.28g of MASiO with a peak wavelength of 640nm 4 :Eu 3+ Red phosphor, 0.32g of silicate green phosphor with a peak wavelength of 540nm and 1.60g of nitride blue phosphor with a peak wavelength of 458nm, the three phosphors are added to the mixed encapsulan...

Embodiment 3

[0050] This embodiment provides a method using MASiO 4 :Eu 3+ A method for realizing a white light LED with a high color gamut of red phosphor powder, comprising the following steps:

[0051] 1) Take 5.80g of encapsulation glue A and 0.58g of encapsulation glue B according to the mass ratio of 10:1, and mix them evenly to obtain a mixed encapsulation glue. The encapsulation glue A is an epoxy-type encapsulation glue, and the encapsulation glue Glue B is a silicone-based packaging glue, the viscosity of the mixed packaging glue is 3700mPa·S, and the refractive index is 1.51;

[0052] 2) Weigh the fluorescent powder according to the emission wavelength of the chip: the chip is an ultraviolet chip, and the emission peak value is 300nm. According to the mass ratio of 10:1:4.5, weigh 4.00g of MASiO with a peak wavelength of 645nm 4 :Eu 3+ Red phosphor, 0.40g of silicate green phosphor with a peak wavelength of 525nm and 1.80g of a nitride blue phosphor with a peak wavelength of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com