Planar compact spiral three-mode filter

A helical filter technology, applied to waveguide devices, circuits, electrical components, etc., can solve the problems of three-mode and multi-mode filter design and miniaturization difficulties, achieve obvious engineering use value, easy to manufacture and promote , the effect of widening the relative bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following embodiments will describe the present invention in detail with reference to the accompanying drawings.

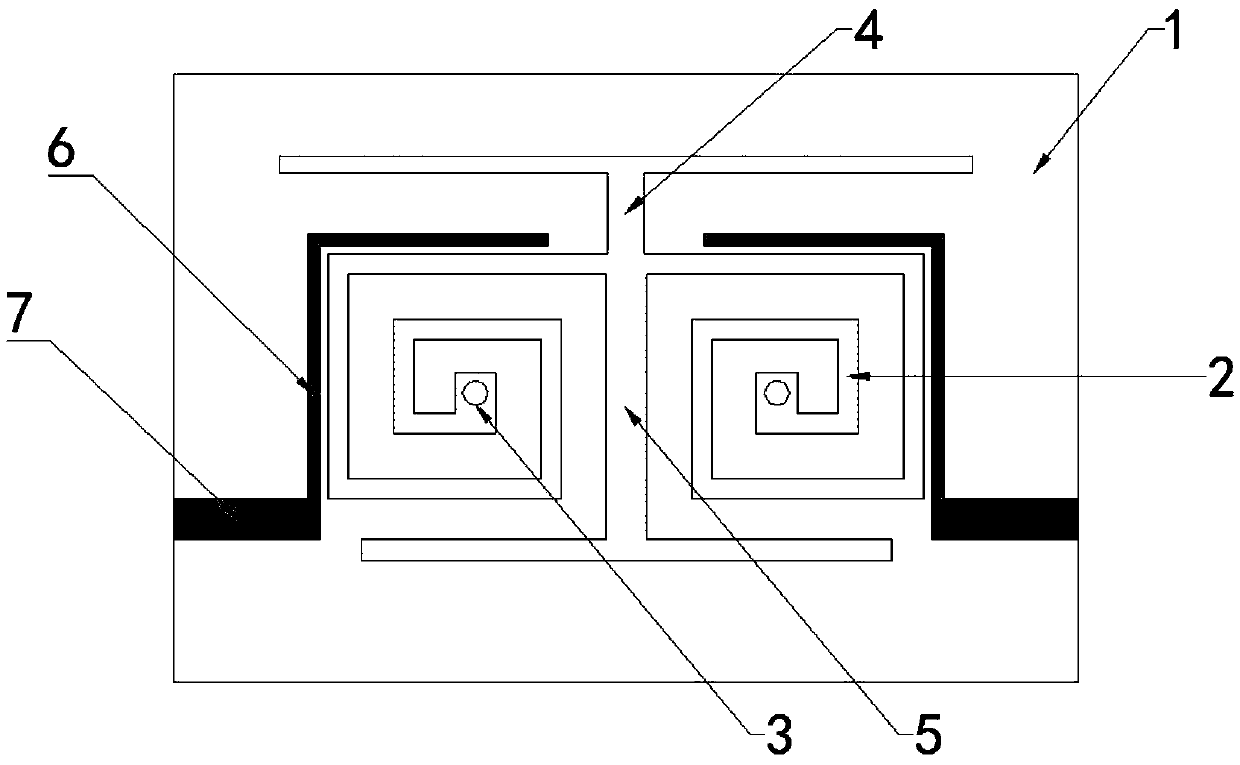

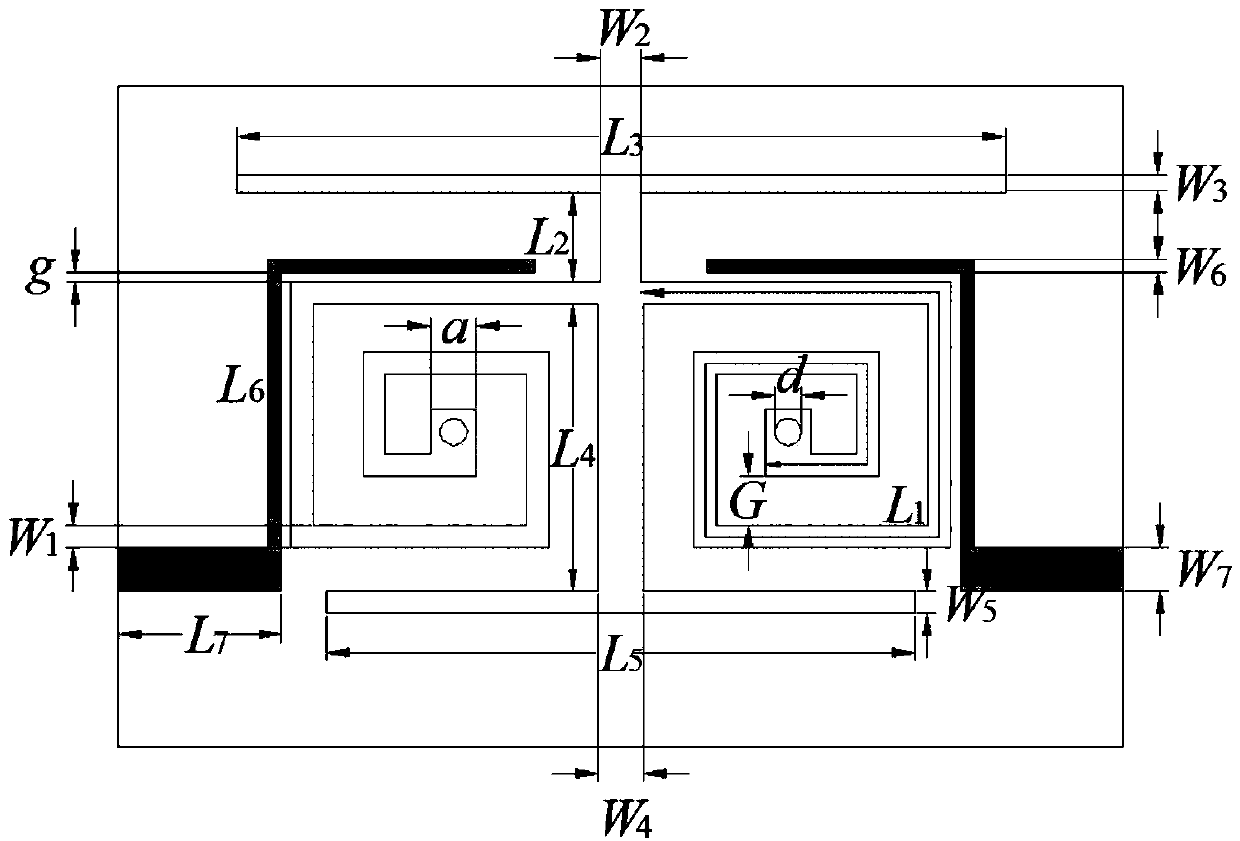

[0023] see figure 1 and 2 , the embodiment of the present invention is provided with a dielectric substrate 1, a spiral resonator 2 with two terminals grounded, a ground via 3, a T-shaped stub microstrip line 4 extending from the center of the resonator to the top, and a T-shaped resonator extending from the center of the resonator to the bottom. T-shaped stub microstrip line 5, coupling line 6, feeder 7 and grounding plate; spiral resonator 2 with two terminals grounded, T-shaped stub microstrip line 4 extending from the center of the resonator to the top, and a T-shaped stub microstrip line extending from the center of the resonator to the bottom The T-shaped stub microstrip line 5, the coupling line 6, and the feeder line 7 are arranged on the upper surface of the dielectric substrate 1, the lower surface of the dielectric substrate 1 is close to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com