Microstructure hard alloy die and hot-pressing micro molding manufacturing method thereof

A technology of hard alloy and manufacturing method, which is applied in the direction of manufacturing tools, glass forming, glass manufacturing equipment, etc., can solve the problems of expensive equipment, short life, low mechanical strength of molds, etc., and achieve low equipment cost, smooth surface, and enhanced The effect of energy saving and emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

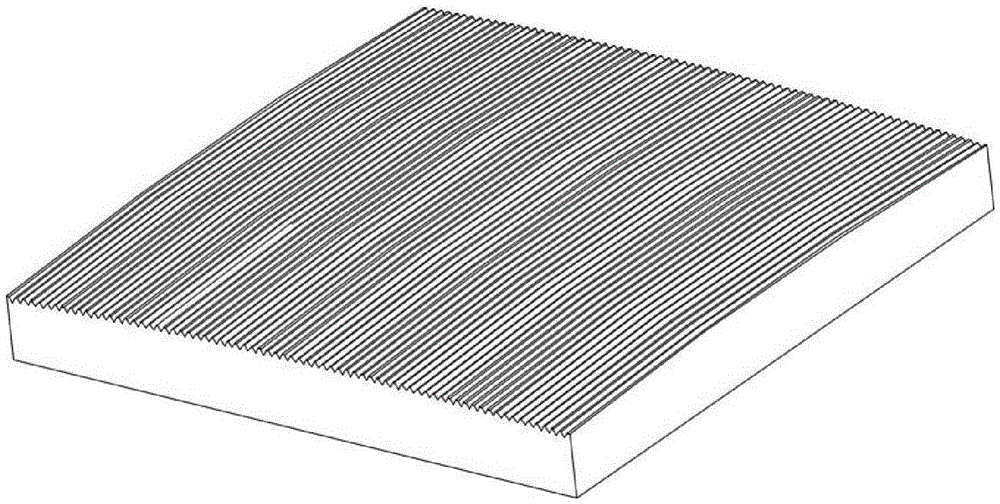

[0039] Such as figure 1 and image 3 As shown, a microstructure hard alloy mold includes a hard alloy mold core with micro grooves, and the hard alloy mold core with micro grooves is a hard alloy mold core with curved micro grooves on the processing surface. A quality alloy mold core 1, the micro-groove array is arranged on the curved surface in parallel, the radius 5 of the curved surface is R=400mm, the groove angle 2 of the micro-groove array is θ=70°, the groove The groove depth 3 is h=0.4mm, and the groove interval 4 is a=0.7mm.

[0040] The microgroove array is used to form the microstructure on the finished product after hot pressing, wherein the processed surface of the hard alloy mold core 1 with curved microgrooves is a curved surface, the purpose of which is to utilize the good optical properties of quartz glass according to research. Performance, through the curved surface micro-groove mold core imprinted on the quartz glass to form a concave micro-groove quartz ...

Embodiment 2

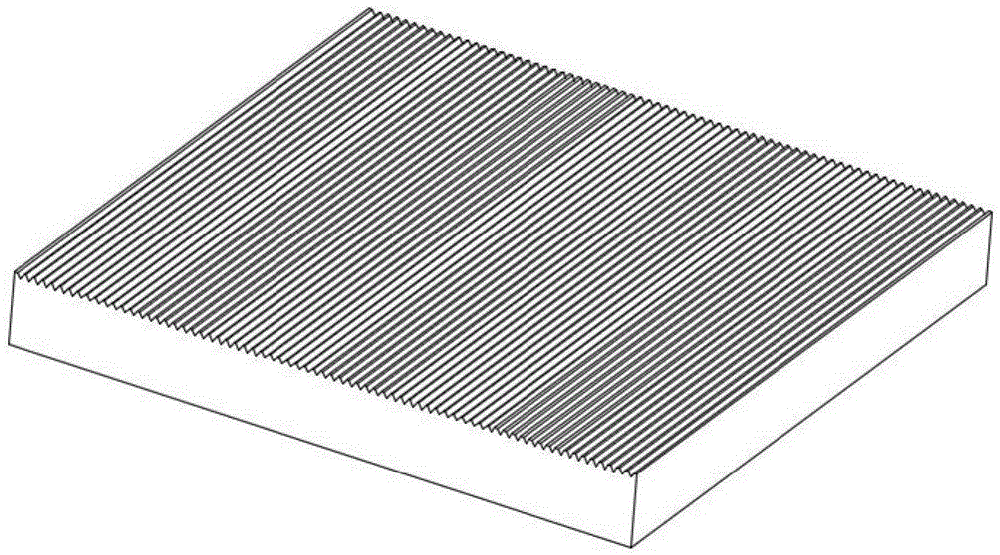

[0042] Such as figure 2 and Figure 4 As shown, a microstructure hard alloy mold includes a hard alloy mold core with micro grooves, and the hard alloy mold core with micro grooves is a hard alloy mold core with flat micro grooves on the processing surface Alloy mold core (15), the micro-groove array is arranged in parallel on the plane, the groove angle 2 of the micro-groove array is θ=50°, and the groove depth 3 is h=0.6mm , the groove interval 4 is a=0.9mm;

[0043] The micro-groove array of the above-mentioned embodiment is processed by the diamond grinding wheel after trimming. Specifically, when processing the curved-surface micro-groove array, firstly, the cemented carbide with curved surface micro-groove is ground into a predetermined size and surface roughness. The mold core 1 is clamped on the vise, and the vise is fixed on the magnetic platform. After adjusting the position, the trimmed coarse-grained diamond grinding wheel is used to pass the curved surface form...

Embodiment 3

[0046] Such as Figure 6 and Figure 7 and Figure 8 As shown, a kind of hot-pressing microforming manufacturing method as described microstructure cemented carbide mould, comprises steps:

[0047] 1) Install the hard alloy mold core 1 with curved surface micro-grooves or the cemented carbide mold core 15 with flat micro-grooves on the upper clamping mold 6 of the thermocompression forming machine through the upper template 12, and pass through the lower template 10 Fix the quartz glass workpiece 8 on the lower clamping mold 7 of the thermocompression forming machine;

[0048] 2) Heat the cemented carbide mold core 1 with curved surface micro-grooves or the cemented carbide mold core 15 with plane micro-grooves to 700°~800° according to the preset temperature parameters of the upper template 12, the predetermined temperature Value is 750 °, and this is realized by template temperature control module 13 on the hot press;

[0049] 3) Clamp the upper and lower molds of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com