Color pavement material and preparation method thereof

A pavement material and color technology, applied in the direction of ceramic products, other household utensils, applications, etc., can solve problems such as the impact of pavement performance, and achieve the effect of dense texture and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0047] Embodiment 1-3: Prepare binder

[0048] The cementitious materials were prepared according to the materials and compositions shown in Table 1, and the cementitious materials A1, A2, and A3 were respectively obtained corresponding to Examples 1-3.

[0049] Table 1 Binder composition and formula

[0050]

Embodiment 4-6

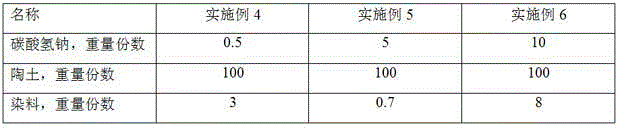

[0051] Embodiment 4-6: Preparation of colored cavity ceramic particles

[0052] The pottery clay used in this example is mainly silty clay mainly composed of kaolinite, montmorillonite, quartz, potassium albite feldspar, etc., and the dyes used are iron oxide red, chromium oxide green, chromium titanium yellow, etc.

[0053] Mix sodium bicarbonate powder, pottery clay powder, and dyes according to the ratio shown in Table 2; add an appropriate amount of water and knead through a kneader to make colored pottery clay containing sodium bicarbonate; pass the pottery clay after the previous step kneading through a screw extruder Extrude and make dense colored clay particles; heat the colored clay particles to the corresponding temperature in a two-stage heating method (see Table 3) and keep for a period of time; continue heating and sintering to make multi-cavity colored ceramic particles. Corresponding to Examples 4-6, the colored cavity ceramic particles B1, B2 and B3 were resp...

Embodiment 7-9

[0059] Embodiment 7-9 prepares colored pavement material

[0060] Take the colored cavity ceramic particles B1, B2 and B3 prepared in Examples 4-6, put them into airtight containers respectively, then vacuumize the container and keep it for 5-20 minutes, so that all the cavities in the particles are in a vacuum state , and then spray the PCM phase change material into the container, the injection amount is 10-50% of the aggregate amount, and keep stirring until all the cavities in the particles are filled with the phase change material.

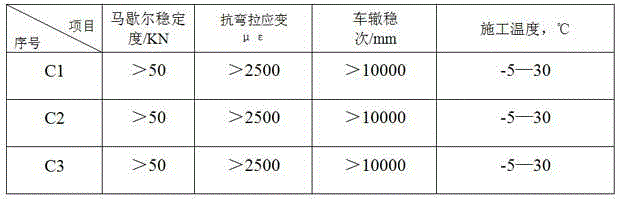

[0061] The colored pavement binders A1, A2, and A3 prepared in Examples 1-3 are mixed with colored ceramic particle aggregates B1, B2, and B3 containing phase change materials respectively to make colored pavement materials C1, C2, and C3. The ratios are: 9 / 100, 10 / 100, 11 / 100. Its road performance is shown in the table below:

[0062] Table 4 Road performance evaluation of colored pavement materials

[0063]

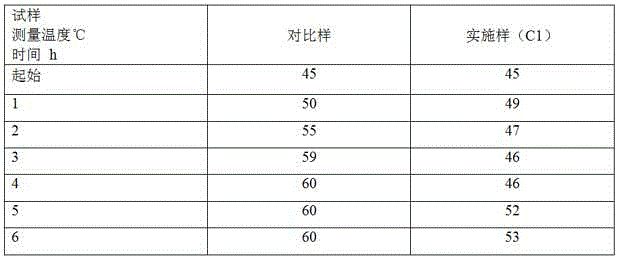

[0064] Table 5 Temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com