A kind of low thermal conductivity magnesia-iron-aluminum spinel brick for cement rotary kiln and production method thereof

A magnesium-iron-aluminum spinel and cement rotary kiln technology, which is applied in applications, household appliances, and other household appliances, can solve problems such as short service life, high production costs, and energy waste, and achieve improved thermal shock resistance. Reduce heat loss and improve operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

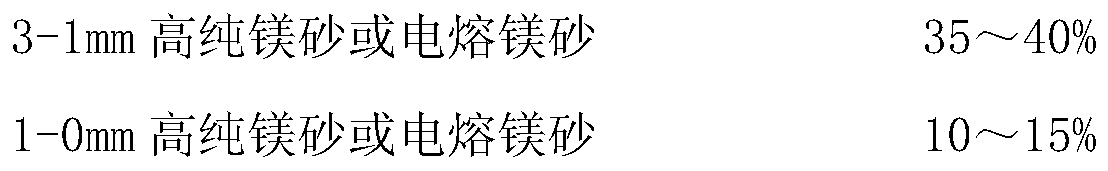

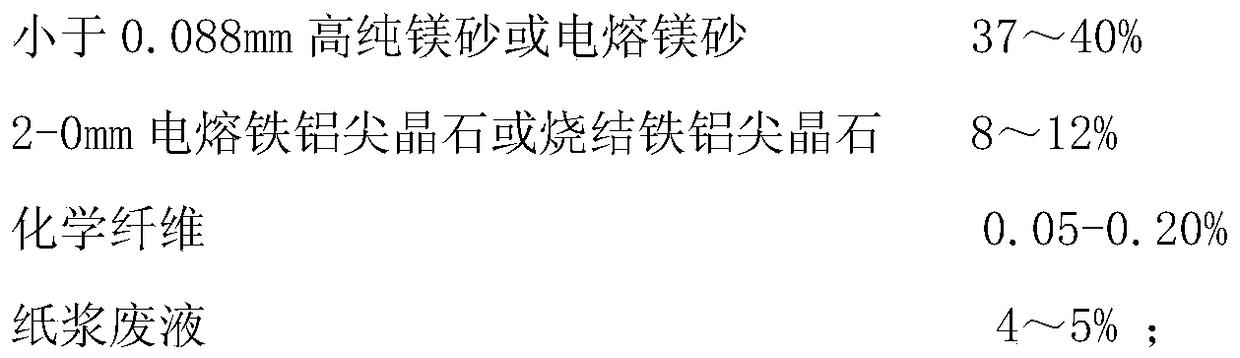

[0023] A magnesia-iron-aluminum spinel brick with low thermal conductivity for a cement rotary kiln, the weight percentage composition of the magnesia-iron-aluminum spinel brick is as follows:

[0024]

[0025] Among them: high-purity magnesia: MgO≥96.5%, SiO 2 3 ; Sintered iron-aluminum spinel: Al 2 o 3 59-62%, Fe 2 o 3 38-41%, SiO 2 <0.5%; chemical fiber: polypropylene ≥99.9%, softening point 180-190°C; pulp waste liquid: specific gravity 1.18-1.20.

[0026] A low thermal conductivity magnesia-iron-aluminum spinel brick for a cement rotary kiln and a production method thereof. The steps of the method are as follows:

[0027] a. According to the weight percentage composition of a kind of low thermal conductivity magnesia-iron-aluminum spinel brick for cement rotary kiln:

[0028]

[0029]

[0030] According to the above ratio, weigh 3-1mm, 1-0mm high-purity magnesia, 2-0mm sintered iron-aluminum spinel, chemical fiber, dry mix and grind in the sand mixer for 2 ...

Embodiment 2

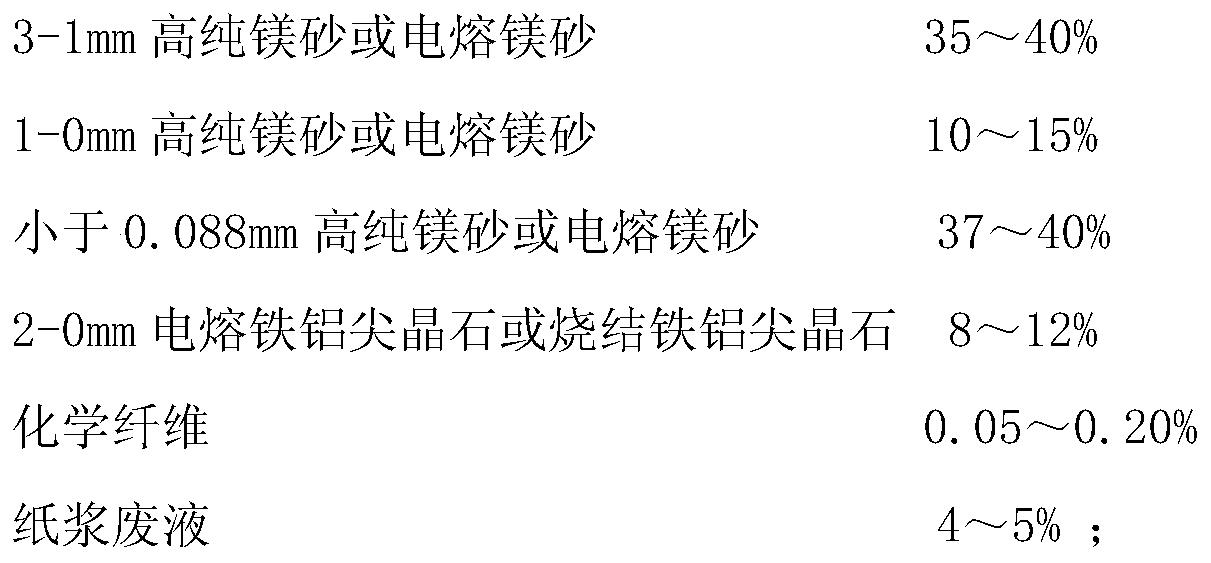

[0035] A magnesia-iron-aluminum spinel brick with low thermal conductivity for a cement rotary kiln, the weight percentage composition of the magnesia-iron-aluminum spinel brick is as follows:

[0036]

[0037] Among them: high-purity magnesia: MgO≥96.5%, SiO 2 3 ; Fused magnesia: MgO≥97.0%, SiO 2 3 ; Fused iron-aluminum spinel: Al 2 o 3 60-62%, Fe 2 o 3 38-40%, SiO 2 2 o 3 59-62%, Fe 2 o 3 38-41%, SiO 2 <0.5%; chemical fiber: polypropylene ≥99.9%, softening point 180-190°C; pulp waste liquid: specific gravity 1.18-1.20.

[0038] A low thermal conductivity magnesia-iron-aluminum spinel brick for a cement rotary kiln and a production method thereof. The steps of the method are as follows:

[0039] a. According to the weight percentage composition of a kind of low thermal conductivity magnesia-iron-aluminum spinel brick for cement rotary kiln:

[0040]

[0041] According to the above ratio, weigh two kinds of magnesia of 3-1mm and 1-0mm and two kinds of ferroalu...

Embodiment 3

[0046] A magnesia-iron-aluminum spinel brick with low thermal conductivity for a cement rotary kiln, the weight percentage composition of the magnesia-iron-aluminum spinel brick is as follows:

[0047]

[0048] Among them: fused magnesia: MgO≥97.0%, SiO 23 ; Fused iron-aluminum spinel: Al 2 o 3 60-62%, Fe 2 o 3 38-40%, SiO 2 <0.5%; chemical fiber: polypropylene ≥99.9%, softening point 180-190°C; pulp waste liquid: specific gravity 1.18-1.20.

[0049] A low thermal conductivity magnesia-iron-aluminum spinel brick for a cement rotary kiln and a production method thereof. The steps of the method are as follows:

[0050] a. According to the weight percentage composition of a kind of low thermal conductivity magnesia-iron-aluminum spinel brick for cement rotary kiln:

[0051]

[0052] According to the above ratio, weigh 3-1mm, 1-0mm fused magnesia, 2-0mm fused iron-aluminum spinel and chemical fibers, and dry mix and grind them in the sand mixer for 3 minutes to make th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com