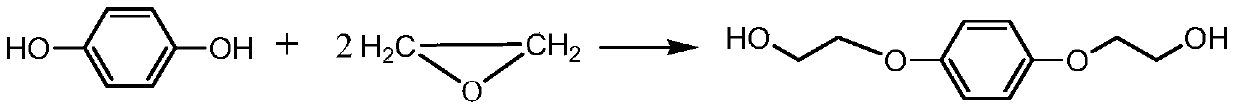

A kind of synthetic method of hydroquinone dihydroxyethyl ether

The technology of dihydroxyethyl ether and hydroquinone, which is applied in the field of organic compound synthesis, can solve problems such as complex process, and achieve the effects of high product purity, few by-products, and effective and reasonable synthesis process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

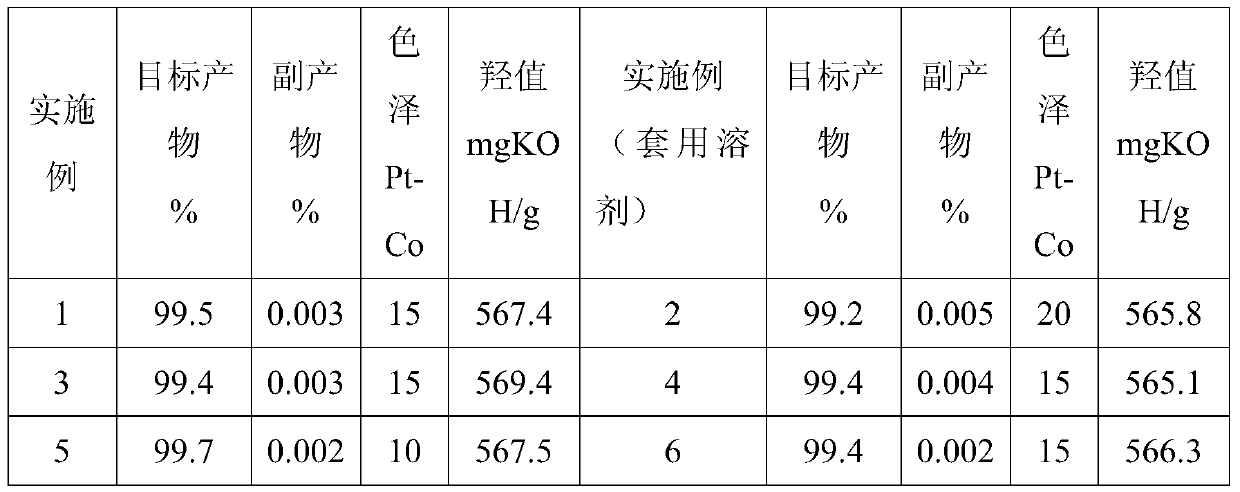

Examples

Embodiment 1

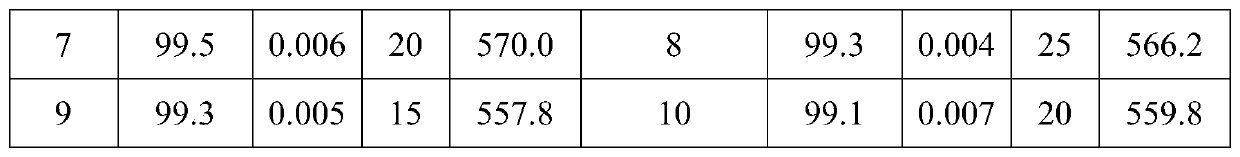

[0034] Add 550g of hydroquinone, 1.0g of 1,1'-bis(diphenylphosphino)ferrocene, and 440g of ethylene glycol di-n-butyl ether into the reaction kettle, vacuumize with a vacuum pump, and replace the inside of the reaction kettle with nitrogen After replacing the air three times, under the protection of nitrogen, the temperature was raised to 110°C, and the temperature was kept for 3-4 hours, and the material in the kettle was completely dissolved. When the hydroquinone is completely melted, vacuumize at this temperature for 20 minutes to remove the low-boiling substances in the kettle, then continue to add 440g of ethylene oxide, and complete the addition within 3 hours, and control the reaction temperature at 125-130°C. The pressure of the reaction kettle is -0.05-0.4Mpa. After adding, keep warm for 7 hours to continue the reaction; after the reaction is completed, cool down to 80°C, vacuum degass to remove unreacted ethylene oxide, and gradually heat up the mother liquor to 125°...

Embodiment 2

[0037]Add 434 g of ethylene glycol di-n-butyl ether recovered in Example 1 together with 550 g of hydroquinone and 1.0 g of 1,1'-bis(diphenylphosphino)ferrocene into the reaction kettle, and vacuumize with a vacuum pump. Use nitrogen to replace the air in the reactor. After three replacements, under the protection of nitrogen, raise the temperature to 110° C., keep the temperature for 3-4 hours, and the materials in the reactor are completely dissolved. When the hydroquinone is completely melted, vacuumize at this temperature for 20 minutes to remove the low-boiling substances in the kettle, then continue to add 440g of ethylene oxide, and complete the addition within 3 hours, and control the reaction temperature at 125-130°C. The pressure of the reaction kettle is -0.05-0.4Mpa. After adding, keep warm for 7 hours to continue the reaction; after the reaction is completed, cool down to 80°C, vacuum degass to remove unreacted ethylene oxide, and gradually heat up the mother liquo...

Embodiment 3

[0040] Add 550g of hydroquinone, 0.5g of 1,1'-bis(diphenylphosphino)ferrocene, and 330g of diethylene glycol diethyl ether into the reactor, vacuumize with a vacuum pump, and replace the nitrogen in the reactor with nitrogen. After the air is replaced three times, under the protection of nitrogen, the temperature is raised to 100 ° C, and the temperature is kept for 3-4 hours, and the material in the kettle is completely dissolved. When the hydroquinone is completely melted, vacuumize at this temperature for 20 minutes to remove the low-boiling substances in the kettle, then continue to add 484g of ethylene oxide, and complete the addition within 4 hours, and control the reaction temperature at 130-135°C. The pressure of the reaction kettle is -0.05-0.4Mpa. After adding, keep warm for 5 hours to continue the reaction; after the reaction is completed, cool down to 80°C, vacuum degass to remove unreacted ethylene oxide, and gradually heat up the mother liquor to 115°C and distill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com