Carpet longitudinal cutting method and system based on computer vision technology

A computer vision and carpet technology, which is applied in the field of automatic longitudinal cutting of carpets based on computer vision technology, can solve the problems of affecting the image processing speed, the vertical cutting device does not have an automatic deviation correction device, and increases the cost of the device, so as to improve the cutting quality and production efficiency , enhance core competitiveness, reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

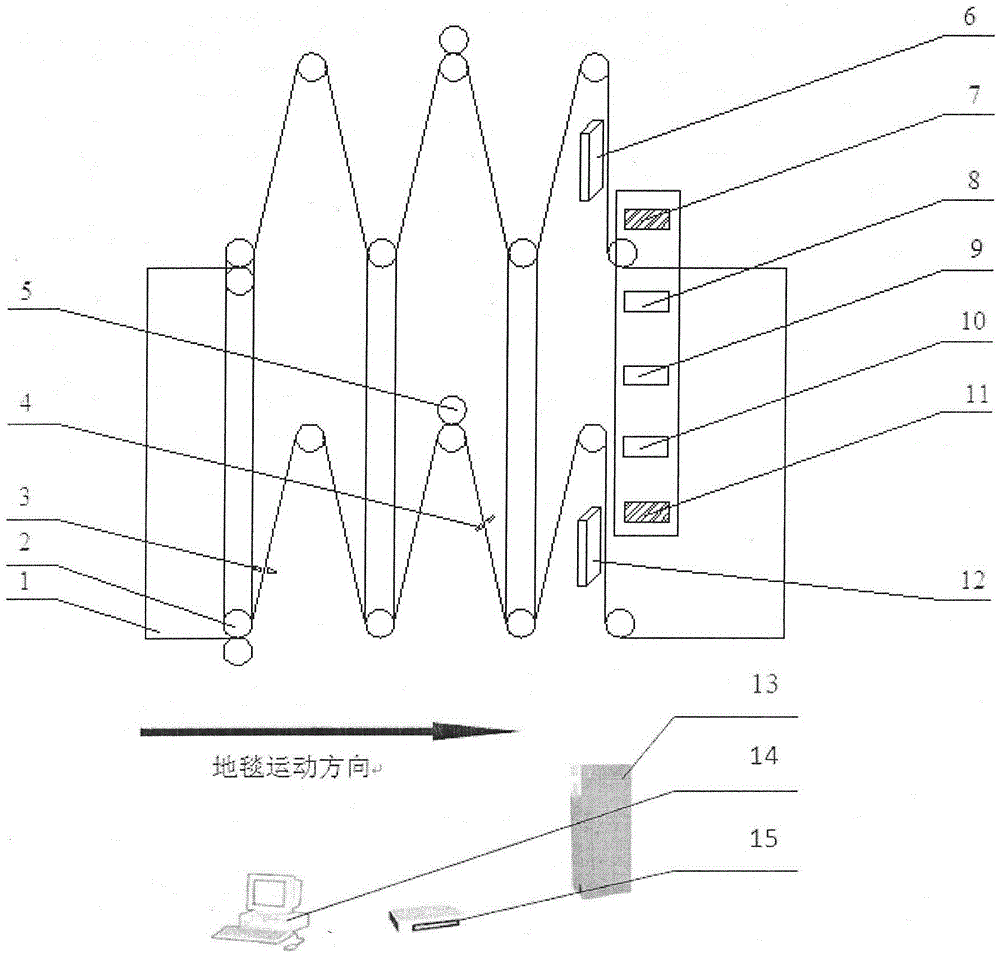

[0050] Such as Figure 6 As shown, the present embodiment cuts a wide carpet into two narrow carpets.

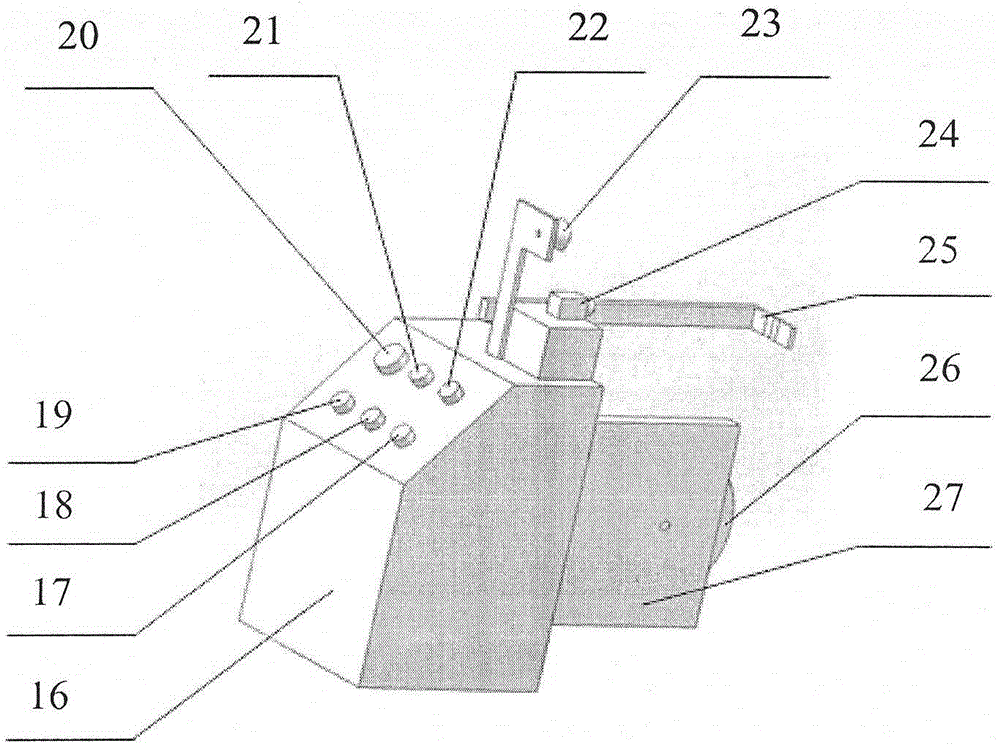

[0051] Turn on the host computer and open the carpet automatic cutting software. Manually press the start button on the knife seat, the disc knife starts to rotate, and manually adjust the knife seat to move left and right, so that the middle black line on the scale is aligned with the cutting position of the edge of the carpet, that is, the cutting position of the disc blade is aligned with the edge of the carpet. Manually adjust the knife seat to advance, so that the disc knife cuts into the carpet and just enters the narrow gap of the vertical steel plate. Another set of automatic trimming device operation is the same.

[0052] Choose one of the three sets of intermediate slitting devices, manually press the start button on the knife seat, the disc knife starts to rotate, and manually adjust the knife seat to move left and right, so that the trapezoidal thin steel sheet...

Embodiment 2

[0069] Such as Figure 7 As shown, in the present embodiment, only the carpet needs to be trimmed automatically. The difference from Example 1 is that no intermediate slitting device is required to participate in the cutting.

Embodiment 3

[0071] Such as Figure 8 As shown, in the present embodiment, two sets of intermediate slitting devices are needed to cut the large wide carpet into three narrow carpets. The difference from Example 1 is that two sets of intermediate slitting devices are required to participate in the cutting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com