A kind of preparation method of red ginseng paste

A technology of red ginseng ointment and ginseng, which is applied to medical preparations, pharmaceutical formulations, plant raw materials and other directions containing active ingredients, can solve the problems of long processing cycle, high energy consumption and high production cost, and achieves shortened production cycle and improved product quality. Good color and light browning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

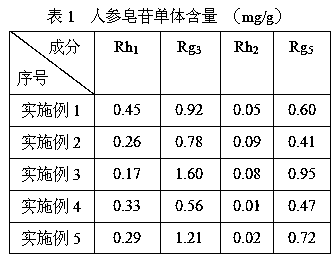

Examples

Embodiment 1

[0020] 1. The raw ginseng used is as follows: fresh ginseng;

[0021] Two, the steps and conditions of preparation are as follows:

[0022] (1) Alcohol extraction: crush fresh ginseng, put it into an extraction tank for extraction, heat reflux extraction with 80% ethanol for 2 h, add alcohol 8 times the total mass of fresh ginseng, and extract once; combine the extracts, Filtrate, concentrate under reduced pressure and recover ethanol to obtain alcohol extraction extract;

[0023] ⑵Steaming: put the alcohol extraction extract in a steaming ginseng cabinet and steam it with high-temperature steam, keep it at 110°C for 4 hours, and cool it to room temperature after steaming;

[0024] (3) Dissolving: dissolve the steamed alcohol extract in (2) with 10 times of water, and filter to obtain the filtrate;

[0025] (4) Water extraction: put the ginseng residue in (1) into the extraction tank for extraction, heat reflux extraction for 3 hours, add water 10 times the total mass of gin...

Embodiment 2

[0030] 1. The raw ginseng used is as follows: fresh ginseng;

[0031] Two, the steps and conditions of preparation are as follows:

[0032] (1) Alcohol extraction: crush fresh ginseng, put it into an extraction tank for extraction, heat reflux with 90% ethanol for 1 h, add alcohol to 6 times the total mass of fresh ginseng, and extract twice; combine the extracts, filter, Concentrate and recover ethanol under reduced pressure to obtain alcohol extraction extract;

[0033] ⑵Steaming: Put the alcohol extraction extract in a steaming ginseng cabinet and steam it with high-temperature steam, keep it at 120°C for 1 hour, and cool it to room temperature after steaming;

[0034] (3) Dissolving: dissolve the steamed alcoholic extract in (2) with 30 times of water, and filter to obtain the filtrate;

[0035] (4) Water extraction: put the ginseng residue in (1) into the extraction tank for extraction, heat reflux extraction for 2 hours, add water 8 times the total mass of ginseng, and...

Embodiment 3

[0039] 1. The raw ginseng used is as follows: fresh ginseng;

[0040] Two, the steps and conditions of preparation are as follows:

[0041] (1) Alcohol extraction: crush fresh ginseng, put it into an extraction tank for extraction, heat reflux extraction with 95% ethanol for 0.5 h, add alcohol 3 times the total mass of fresh ginseng, and extract 3 times; combine the extracts, filter, Concentrate and recover ethanol under reduced pressure to obtain alcohol extraction extract;

[0042] ⑵Steaming: Put the alcohol extraction extract in a steaming ginseng cabinet and steam it with high-temperature steam, keep it at 130°C for 0.5h, and cool it to room temperature after steaming;

[0043] (3) Dissolving: dissolve the steamed alcohol extract in (2) with 50 times of water, and filter to obtain the filtrate;

[0044] (4) Water extraction: put the ginseng residue in (1) into an extraction tank for extraction, heat reflux for extraction for 1 hour, add water 5 times the total mass of gi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com