Mesh cloth for sewage treatment and preparation method of mesh cloth

A technology for sewage treatment and mesh cloth, which is applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc. The effect of sewage treatment performance, controllable preparation process and wide source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A mesh cloth for sewage treatment is characterized in that it is obtained by three-dimensional weaving of a warp knitting machine, the thickness of the mesh cloth is 10 mm, and the water permeability of the mesh cloth for sewage treatment is greater than 1800 mm·s -1 , the burst strength is greater than 2000N.

[0045] A method for preparing a mesh cloth for sewage treatment, characterized in that the specific steps are:

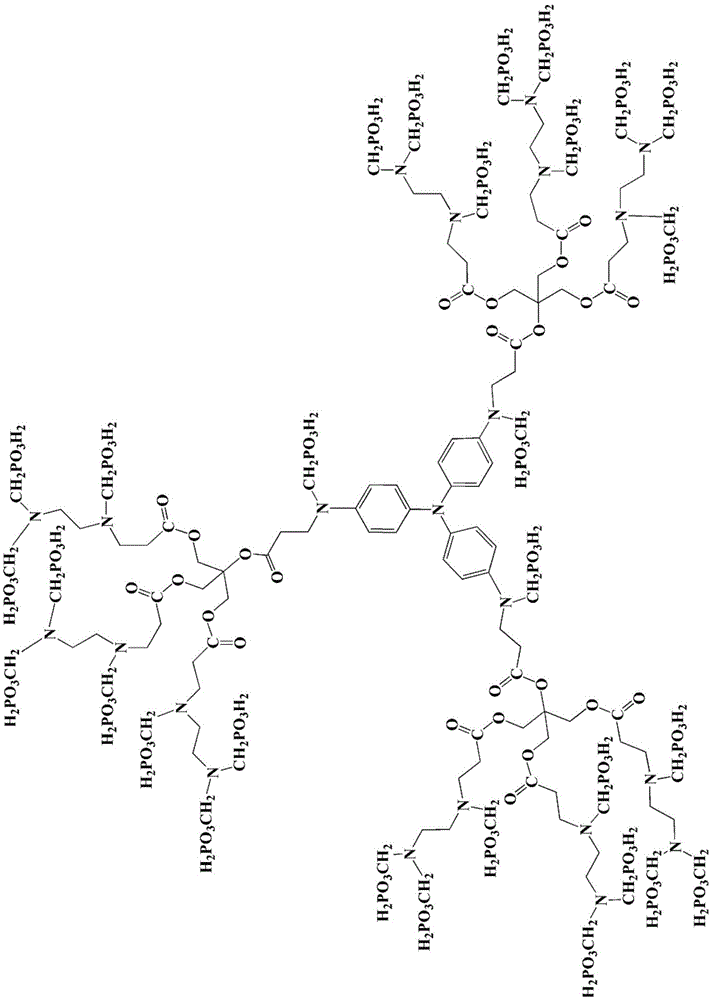

[0046] (1) Preparation of phosphonic acid-terminated hyperbranched dendrimers

[0047] The structural formula of phosphonic acid-terminated hyperbranched dendrimers is as follows figure 1 shown:

[0048] The application of the phosphonic acid-terminated hyperbranched dendrimer is mainly applied to the adsorption treatment of heavy metal ions in water;

[0049] Passivator with high algebra, due to the high content of phosphonic acid group in the molecule, strong chelation effect with heavy metal ions, large number of chelated metal ions in a single ...

Embodiment 2

[0072] A mesh cloth for sewage treatment, characterized in that it is obtained by three-dimensional weaving by a warp knitting machine, the thickness of the mesh cloth is 50 mm, and the water permeability of the mesh cloth for sewage treatment is greater than 1800 mm s -1 , Bursting strength greater than 2000N.

[0073] A kind of preparation method of mesh cloth for sewage treatment is characterized in that, its specific steps are:

[0074] (1) Preparation of phosphonic acid-terminated hyperbranched dendrimers

[0075] The structural formula of phosphonic acid terminal hyperbranched dendrimers is as follows figure 1 Shown:

[0076] The application of the phosphonic acid terminal hyperbranched dendritic polymer is mainly applied to the adsorption treatment of heavy metal ions in water;

[0077] Passivating agent with high algebra, due to the high content of phosphonic acid groups in the molecule, it has a strong chelation effect with heavy metal ions, and the chelation numbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| mole fraction | aaaaa | aaaaa |

| mole fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com