Regeneration method of arsenic poisoning denitration catalyst

A denitration catalyst, arsenic poisoning technology, applied in catalyst regeneration/reactivation, molecular sieve catalyst, chemical instruments and methods, etc. The effect of expanding industrial use, enhancing activity, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

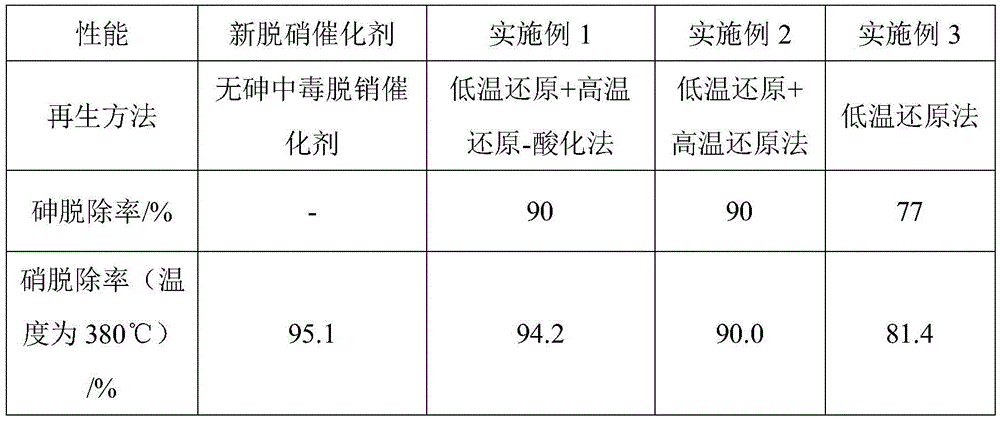

Embodiment 1

[0019] Using plate type V 2 o 5 -MoO 3 / TiO 2 The denitrification catalyst runs for 24,000 hours in a flue gas environment with high arsenic content, causing it to be poisoned by arsenic.

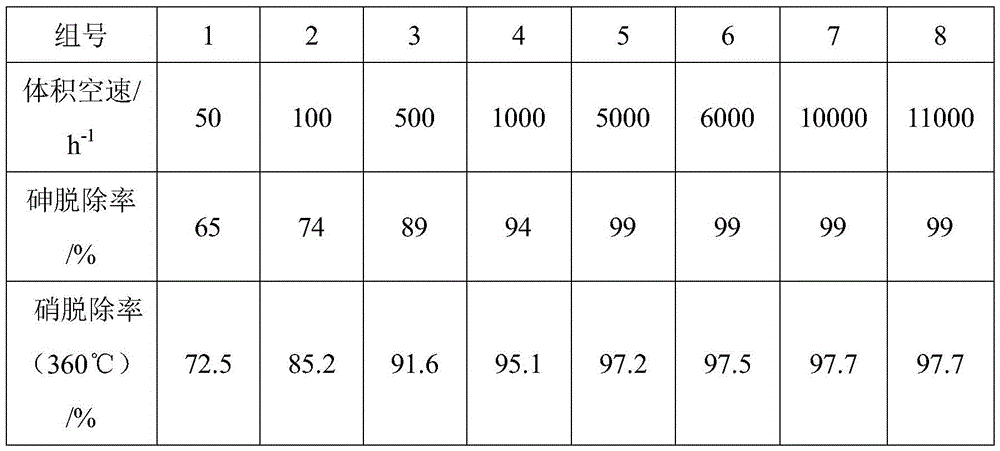

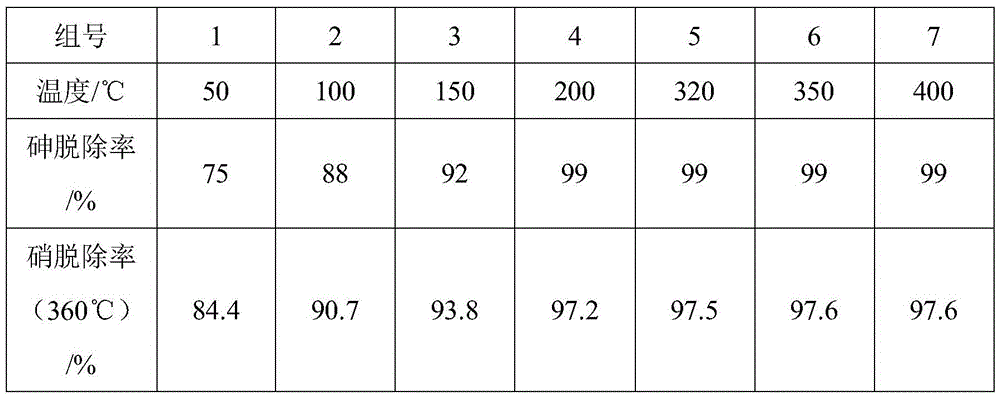

[0020] Regenerate the arsenic-poisoned denitrification catalyst, the method includes the following steps: first remove the fly ash on the surface of the denitrification catalyst and in the pores, place it in a stainless steel reactor, and feed it with a volumetric space velocity of 500h -1 The synthesis gas of the reactor is raised to 320°C, and the reduction reaction is carried out for 5 hours; the synthesis gas is continued, and the temperature of the reactor is raised to 500°C, and at the same time, 1500ppm of SO is injected into the reactor 2 , carry out the reduction-acidification reaction, and react for 1h to obtain the regenerated denitration catalyst, wherein the synthesis gas includes CO, H 2 , N 2 , CO 2 and CH 4 , CO and H 2 80% of the total.

[0021] The regenerated den...

Embodiment 2

[0024] Design a comparative experiment, carry out the reduction reaction at low temperature and high temperature in turn, but the reduction reaction at high temperature is no longer combined with the acidification reaction, the specific steps are: use the plate V 2 o 5 -MoO 3 / TiO 2 For the denitrification catalyst, first make it run for 24000h in the flue gas environment with high arsenic content to cause arsenic poisoning, first remove the fly ash on the surface of the denitrification catalyst and in the pores, and place it in a stainless steel reactor with a volumetric space velocity of 500h -1The synthesis gas is raised to 320°C in the reactor, and the reduction reaction is carried out for 5 hours; the synthesis gas is continuously fed in, and the temperature of the reactor is raised to 500°C, and after 1 hour of reaction, the regenerated denitration catalyst is obtained, wherein , the synthesis gas includes CO, H 2 , N 2 , CO 2 and CH 4 , CO and H 2 80% of the tota...

Embodiment 3

[0027] Design a comparative experiment, only carry out the reduction reaction at low temperature, do not carry out the reduction-acidification reaction at high temperature, the specific steps are: first put the plate V 2 o 5 -MoO 3 / TiO 2 The denitrification catalyst was operated for 24000h in a flue gas environment with high arsenic content to poison it with arsenic, then remove the fly ash on the surface of the denitrification catalyst and in the pores, and put it in a stainless steel reactor with a volumetric space velocity of 500h -1 The synthesis gas of the reactor is raised to 320°C and reacted for 5 hours to obtain the regenerated denitration catalyst, wherein the synthesis gas includes CO, H 2 , N 2 , CO 2 and CH 4 , CO and H 2 80% of the total.

[0028] Put the regenerated denitration catalyst prepared above into a fixed-bed microreactor for evaluation. The temperature in the reactor is 300°C, and the simulated flue gas composition is NO concentration of 450ppm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com