Fine processing technology of rice

A technology of rice and technology, applied in application, grain processing, agriculture, etc., can solve the problems of low rice whole rice rate and rice yield rate, reduce broken rice rate, reduce broken and cracked rice, and reduce soluble amylopectin content of rice Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

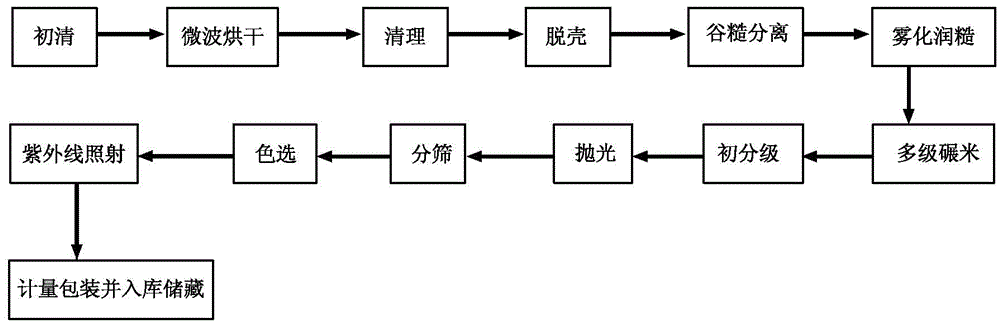

[0022] A rice finishing process, comprising the following steps: initial cleaning→microwave drying→cleaning→husking→separation of paddy and coarse grains→atomization and moistening→multi-stage rice milling→primary grading→polishing→sieving→color sorting→ultraviolet rays Irradiation→Measurement packaging and warehouse storage.

[0023] Early cleaning: The old or new sun-dried rice is first checked and accepted by the chemical industry to ensure that it meets the national standard GB1350, and then sent to the vibrating cleaning screen to remove large and medium impurities such as large gravel and sand.

[0024] Microwave drying: The rice after initial cleaning is sent to microwave drying equipment for drying treatment until its moisture content is 12%, and the working temperature of microwave drying equipment is 50°C. The rice is dried by microwave through the microwave drying equipment, which can increase the soluble amylopectin content of the rice, so that the rice processed b...

Embodiment 2

[0037] The processing method of this embodiment is consistent with the process of embodiment 1, and the working temperature of the microwave drying equipment is 45°C. After the rice is dried, the water content of the rice reaches 13%.

Embodiment 3

[0039] The processing method of this embodiment is consistent with the process of embodiment 1, and the working temperature of the microwave drying equipment is 47°C. After the rice is dried, the water content of the rice reaches 13%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com