Palladium nano-particles with peroxidase activity and preparation method thereof

A palladium nanoparticle, peroxidase technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of low peroxidase activity, difficult to control conditions, and complicated preparation. and other problems, to achieve the effect of simple method, easy control of conditions and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of palladium nanoparticles with peroxidase activity, comprising the steps of:

[0036] (1) Deoxynucleotide C 10 The annealing of:

[0037] Dissolve 25 μL of 20 μM deoxynucleotide C 10 Add aqueous solution, 100 μL of 10 mM sodium dihydrogen phosphate-disodium hydrogen phosphate buffer solution with a pH of 5.0 to a 1.5 mL centrifuge tube and add triple distilled water to make the total volume 400 μL, mix well; heat up to 95 °C, maintain for 5 min, and cool down to room temperature;

[0038] (2) Preparation of palladium nanoparticles:

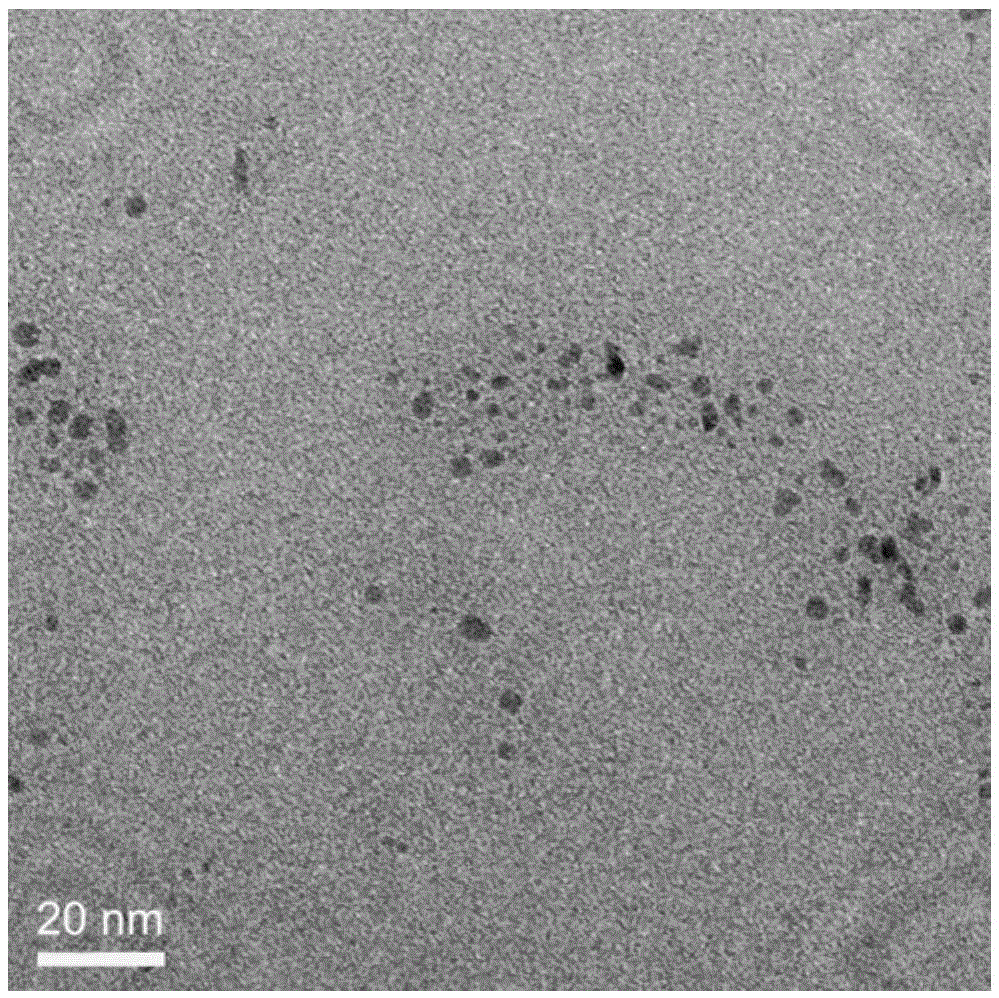

[0039] Add 12 μL of 300 μM sodium chloropalladate aqueous solution to the annealed deoxynucleotide aqueous solution obtained in step (1), mix well at 25°C, let it stand for 2 hours, add 15 μL of 1.5mM dimethylamine borane aqueous solution, mix well, and After standing at 25°C for 12 hours, a palladium nanoparticle liquid with peroxidase activity was obtained. The average particle size obtained by scanning with a tr...

Embodiment 2

[0047] A preparation method of palladium nanoparticles with peroxidase activity, comprising the steps of:

[0048] (1) Deoxynucleotide G 200 The annealing of:

[0049] 2.5 μL of 2 μM deoxynucleotide G 200 Add aqueous solution, 50 μL 5 mM potassium dihydrogen phosphate-dipotassium hydrogen phosphate buffer solution with a pH of 3.0 to a 1.5 mL centrifuge tube, add triple distilled water to make the total volume 400 μL, mix well; heat up to 90 °C, maintain for 10 min, and cool down to room temperature;

[0050] (2) Preparation of palladium nanoparticles:

[0051] Add 8 μL of 200 μM sodium chloropalladate aqueous solution to the annealed deoxynucleotide aqueous solution obtained in step (1), mix well at 20°C, let it stand for 4 hours, add 6 μL of 0.6mM sodium borohydride aqueous solution, mix well, and heat at 20°C Stand still for 15 hours to obtain a palladium nanoparticle liquid with peroxidase activity.

[0052] The average particle size obtained by scanning with a transmi...

Embodiment 3

[0054] A preparation method of palladium nanoparticles with peroxidase activity, comprising the steps of:

[0055] (1) Deoxynucleotide C 200 The annealing of:

[0056] Dissolve 250 μL of 200 μM deoxynucleotide C 200Add aqueous solution, 200 μL 20 mM sodium dihydrogen phosphate-phosphoric acid solution with a pH of 9.0 to a 1.5 mL centrifuge tube and add triple distilled water to make the total volume 400 μL, mix well; heat up to 100 °C, maintain for 5 min, and cool down to room temperature;

[0057] (2) Preparation of palladium nanoparticles:

[0058] Add 16 μL of 400 μM sodium chloropalladate aqueous solution to the annealed deoxynucleotide aqueous solution obtained in step (1), mix well at 30° C., let stand for 0.5 h, add 24 μL 2.4 mM dimethylamine borane aqueous solution, mix well, Standing at 30° C. for 10 h, a palladium nanoparticle liquid with peroxidase activity was obtained.

[0059] The average particle size obtained by scanning with a transmission electron micros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

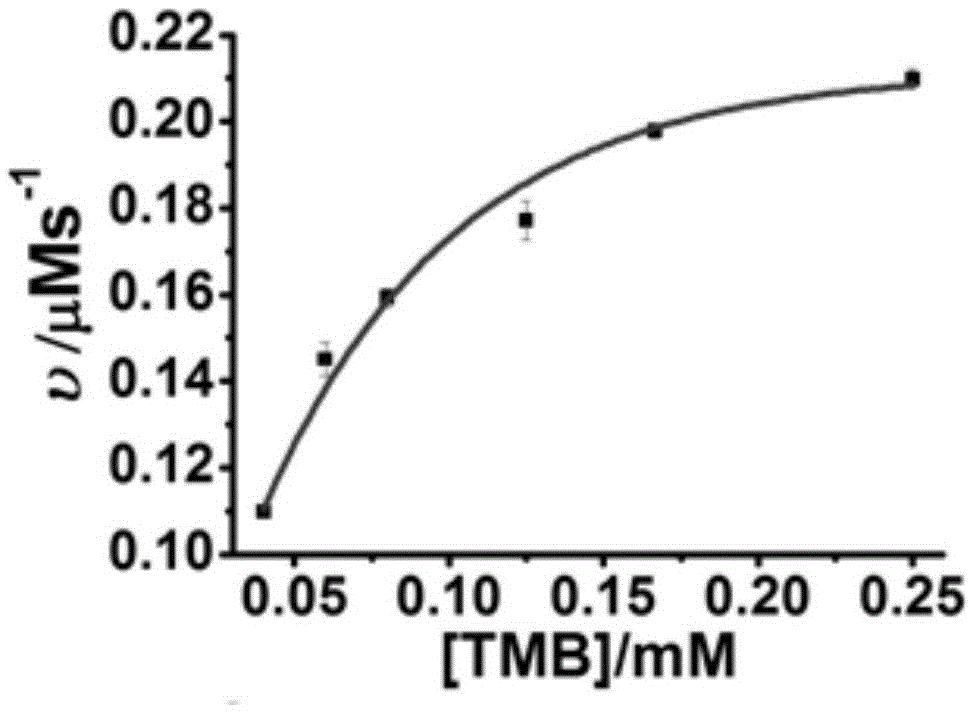

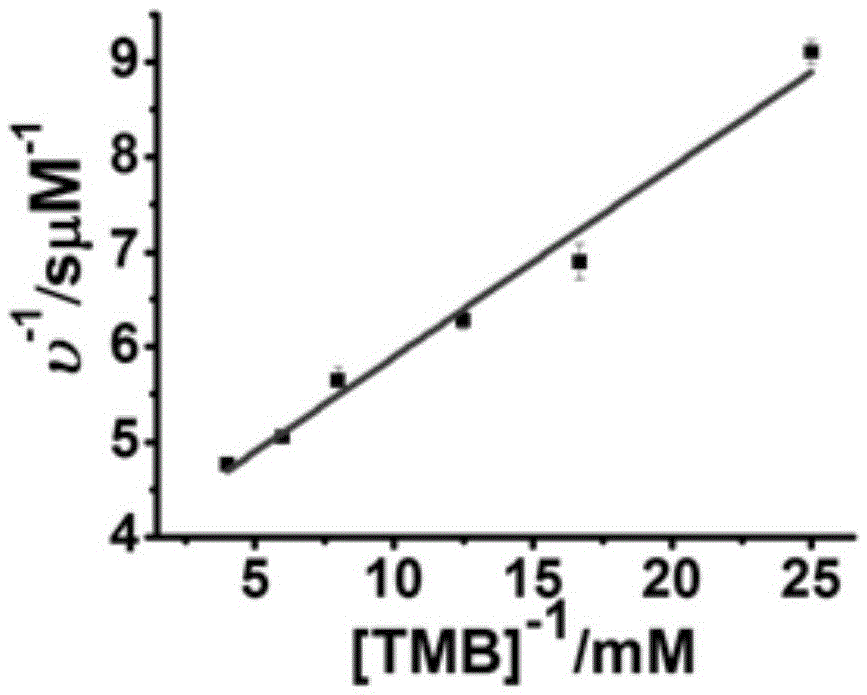

| Km value | aaaaa | aaaaa |

| Km value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com