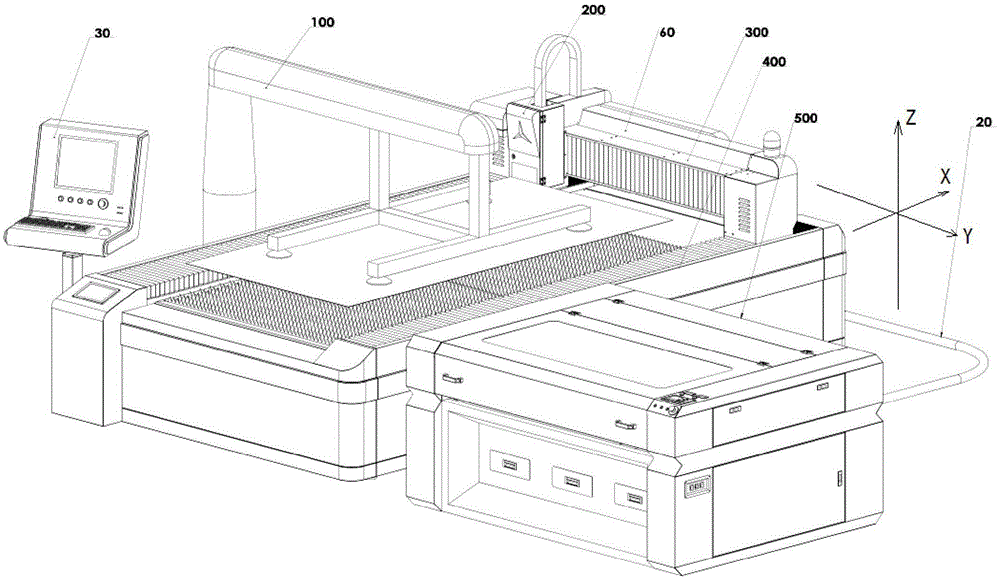

Multifunctional laser cutting and welding integrated machine

An all-in-one, multi-functional technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of increasing production costs and maintenance costs, the promotion of low-power laser cutting machines and welding machines, limiting laser cutting machines and Problems such as the scope of later use of the welding machine, to achieve the effect of compact structure, lower price, and more functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with specific embodiment the embodiment of the present invention is further described:

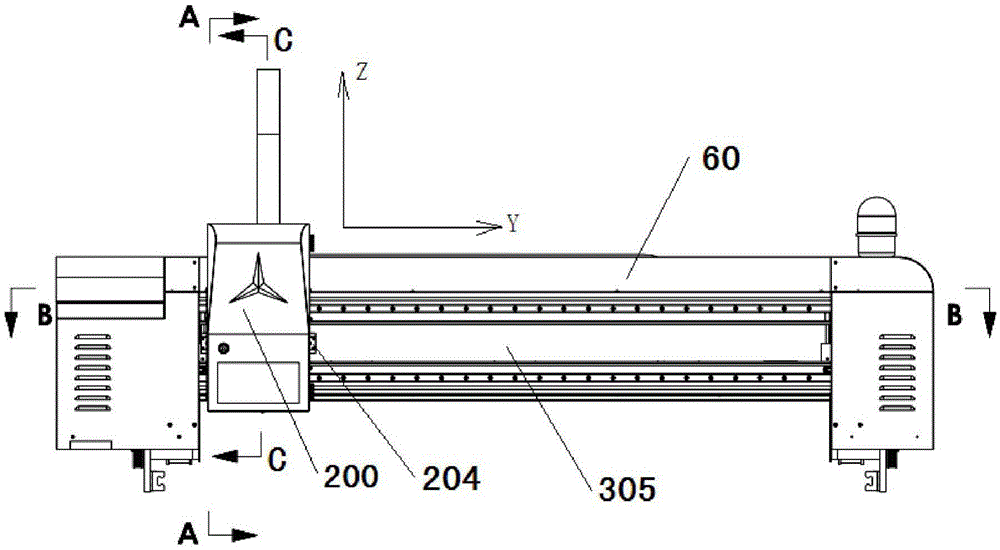

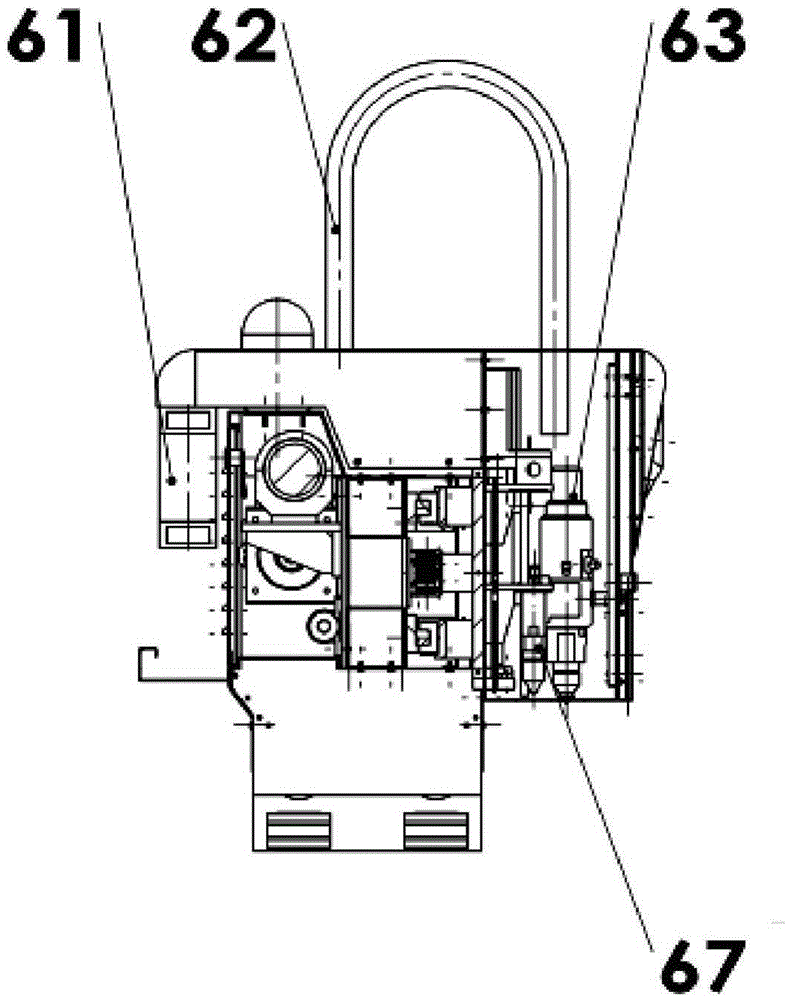

[0029] Such as Figure 8-Figure 9 As shown, a working method of a multi-functional laser cutting and welding machine adopts a set of power switching, time-sharing control CO 2 Two sets of laser equipment and fiber optics, on the same machine tool, can realize alternate metal cutting and welding, or non-metal cutting.

[0030] The equipment is initialized and run, and the work type is identified as CO 2 laser or fiber laser; if CO 2 The laser then powers into the CO 2 Laser Non-Metal Cutting Mode, CO 2 The laser enters the working state of non-metal cutting.

[0031] If the work type is judged as fiber laser, continue to judge whether the task of fiber laser is welding or cutting. If it is cutting, the power supply will enter the fiber laser metal cutting mode, and the fiber laser will enter the metal cutting working state. If it is judged that the working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com