Polishing paste for glass and glass polishing repair method

A polishing paste and glass technology, applied in grinding/polishing equipment, polishing compositions containing abrasives, machine tools suitable for grinding workpiece planes, etc., can solve the problem of unsatisfactory polishing effect, time-consuming and laborious recycling work, Polishing and repairing is time-consuming and labor-intensive, and achieves the effect of remarkable polishing effect, easy cleaning, time-saving and consumables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

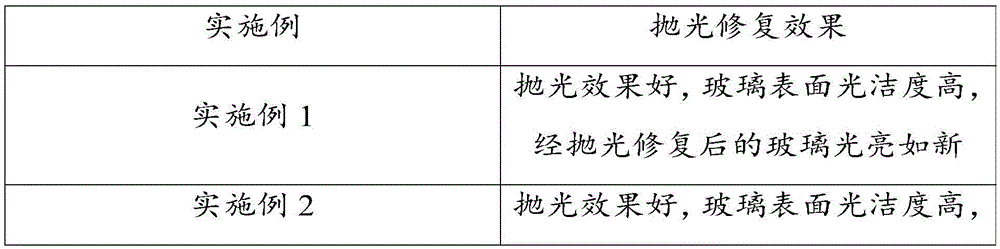

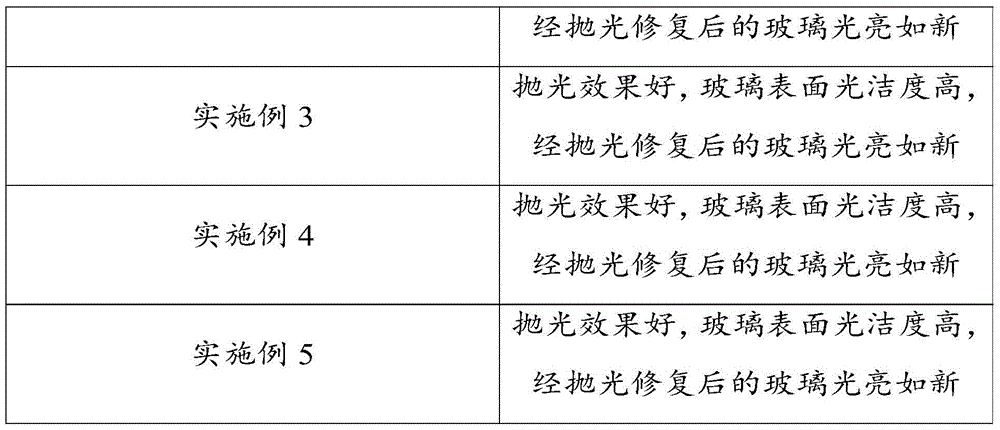

Examples

Embodiment 1

[0084] A polishing paste for glass, which is prepared by uniformly mixing the following components in parts by mass:

[0085] 40 parts of cerium oxide, 10 parts of zirconia, 50 parts of alcohol.

Embodiment 2

[0087] A polishing paste for glass, which is prepared by uniformly mixing the following components in parts by mass:

[0088] 20 parts of cerium oxide, 30 parts of aluminum oxide, and 50 parts of vegetable oil.

Embodiment 3

[0090] A polishing paste for glass, which is prepared by uniformly mixing the following components in parts by mass:

[0091] 25 parts of cerium oxide, 30 parts of chromium oxide, 102 parts of OP-102, 3 parts of behenylamide dimethyl hydroxypropyl ammonium chloride, 40 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com