Preparing method for undersized-log reconstructing outdoor furniture wood

A small-diameter wood, outdoor technology, applied in the direction of wood treatment, impregnated wood, wood impregnation, etc., can solve the problems of no production method, etc., and achieve the effects of improving glue performance, easy industrialization, and increasing bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

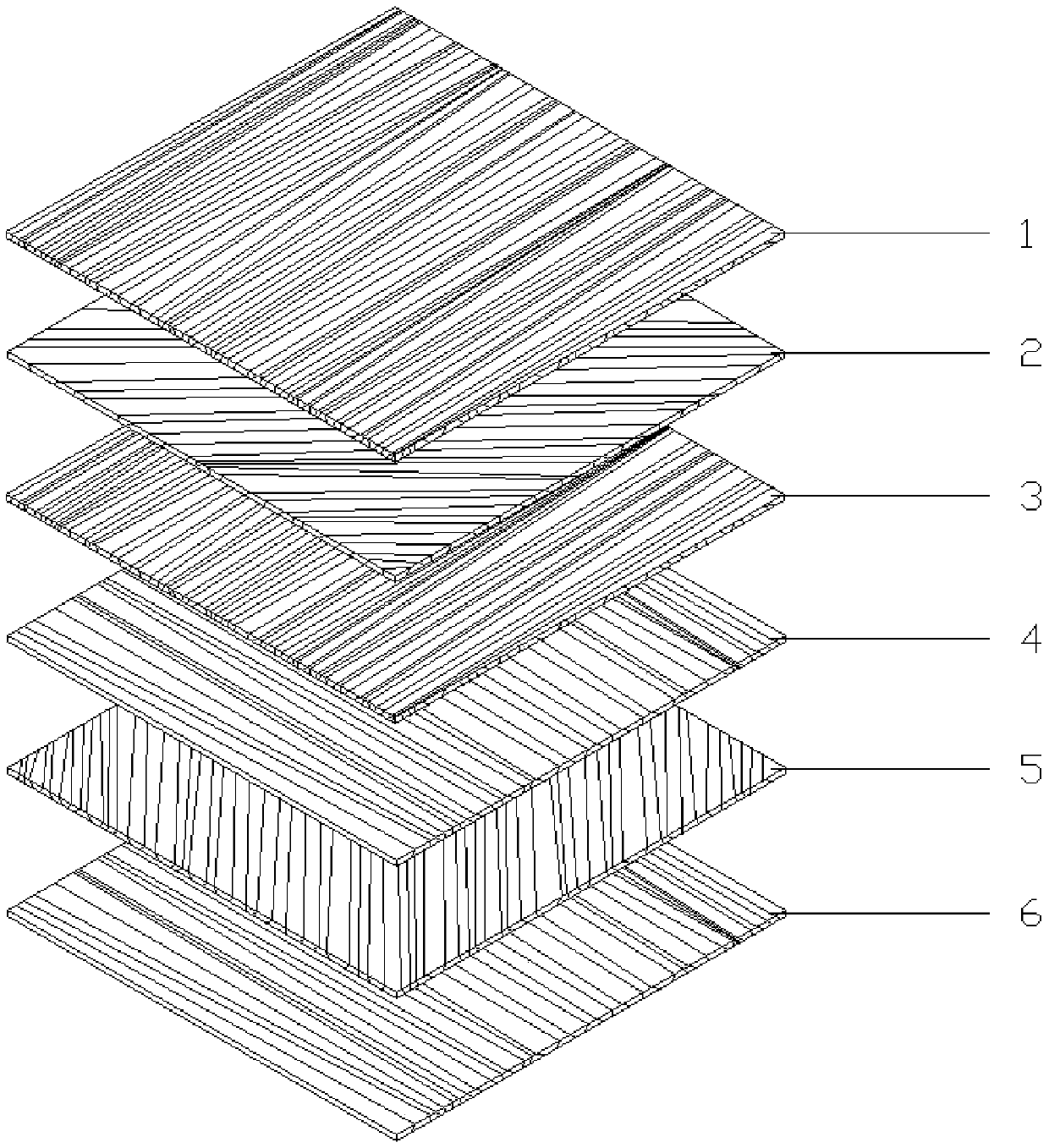

[0016] see figure 1 A method for processing small-diameter wood recombined outdoor furniture materials, comprising the steps of:

[0017] (1) Cut the fresh Vitex stalks with a diameter of less than 4 cm into 35 cm sections, roll them three times, remove the bark, and dry them at 105°C for 10 hours to obtain Vitex stalks. The speed of the rolling machine is 25r / min, and the line pressure is 20N / mm;

[0018] (2) Dilute the phenolic resin solution according to the volume ratio of phenolic resin solution: water = 60: 40, and wait until the reinforcing solution; then according to the volume ratio of Vitex japonica: reinforcing solution = 1: 10, put Vitex vitex in the reinforcing solution at normal temperature and pressure Immerse for 30 hours, then take it out, dry it in the air, and then bake it at 40°C until the water content is 3%, to obtain plasticized Vitex japonica bundles. Wherein the mass percent concentration of the phenolic resin solution is 40%.

[0019] (3) Immerse...

Embodiment 2

[0022] see figure 1 A method for processing small-diameter wood recombined outdoor furniture materials, comprising the steps of:

[0023] (1) Cut the fresh Vitex stalks with a diameter of less than 4 cm into 40 cm sections, roll them three times, remove the bark, and dry them at 105°C for 12 hours to obtain Vitex stalks. The speed of the rolling machine is 28r / min, and the line pressure is 15N / mm;

[0024] (2) Dilute the phenolic resin solution according to the volume ratio of phenolic resin solution: water=55:45, wait until the enhancement solution; then according to the volume ratio of Vitex japonica: enhancement solution=1:15, place the Vitex vitae bundle in the enhancement solution at normal temperature and pressure Immerse for 35 hours, then take it out, dry it in the air, and then bake it at 50°C until the water content is 4%, to obtain plasticized Vitex japonica bundles. Wherein the mass percent concentration of the phenolic resin solution is 45%.

[0025] (3) Imme...

Embodiment 3

[0028] see figure 1 A method for processing small-diameter wood recombined outdoor furniture materials, comprising the steps of:

[0029] (1) Cut the fresh Vitex stalks with a diameter of less than 4 cm into sections of 40 cm, roll them three times, remove the bark, and dry them at 105°C for 14 hours to obtain Vitex stalks. The speed of the rolling machine is 30r / min, and the line pressure is 20N / mm;

[0030] (2) Dilute the phenolic resin solution according to the volume ratio of phenolic resin solution: water=65:35, wait until the enhancement solution; then according to the volume ratio of Vitex japonica: enhancement solution=1:18, place the Vitex vitae bundle in the enhancement solution at normal temperature and pressure Immerse for 32 hours, then take it out, dry it in the air, and then bake it at 55°C until the water content is 5%, to obtain plasticized Vitex japonica bundles. Wherein the mass percentage concentration of phenolic resin solution is 42%;

[0031] (3) Im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com