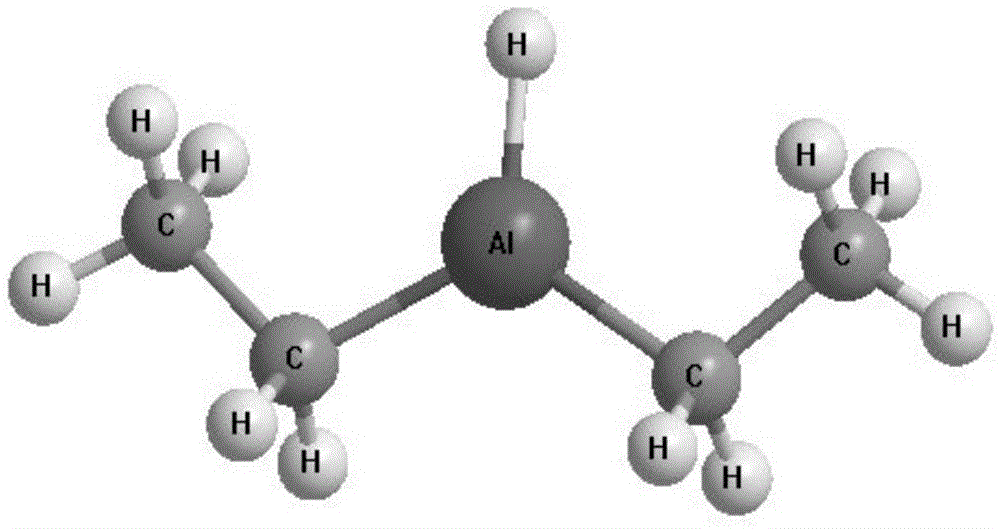

Preparation method for alpha-AlH3 by catalyzing active aluminum with diethyl aluminum hydride and LiBH4 as catalysts

A diethylaluminum hydride, catalytically active technology, applied in chemical instruments and methods, metal hydrides, inorganic chemistry, etc., can solve problems such as harsh conditions, and achieve the effect of simple ideas and simple process methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

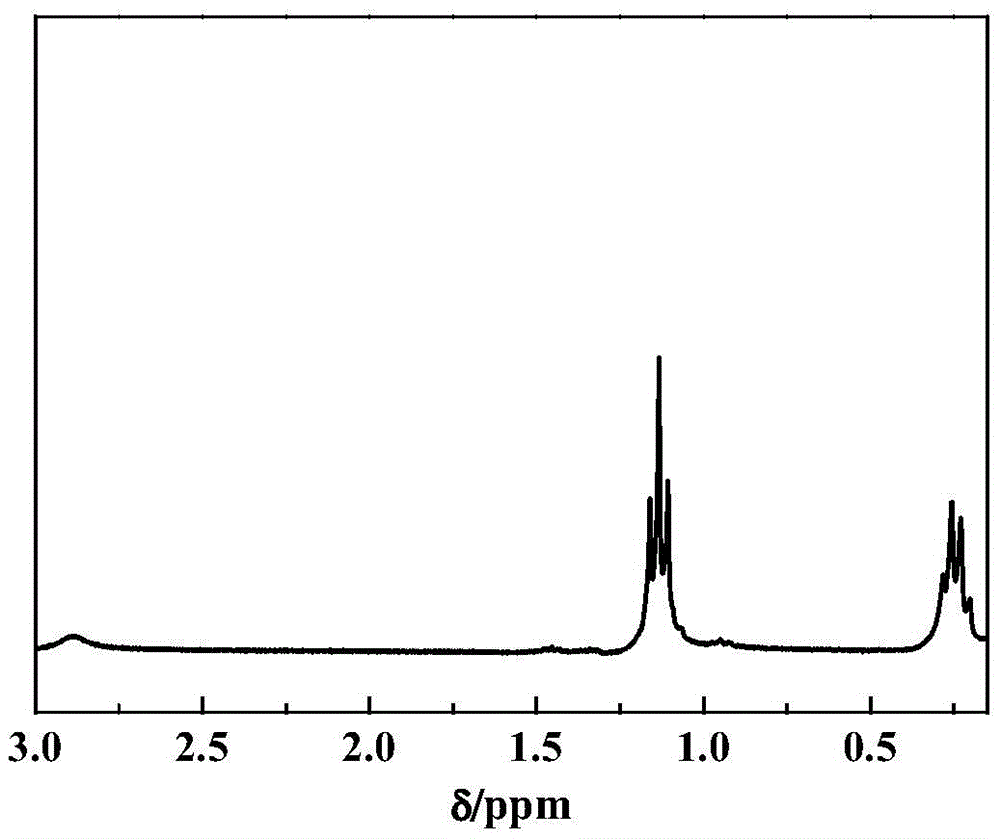

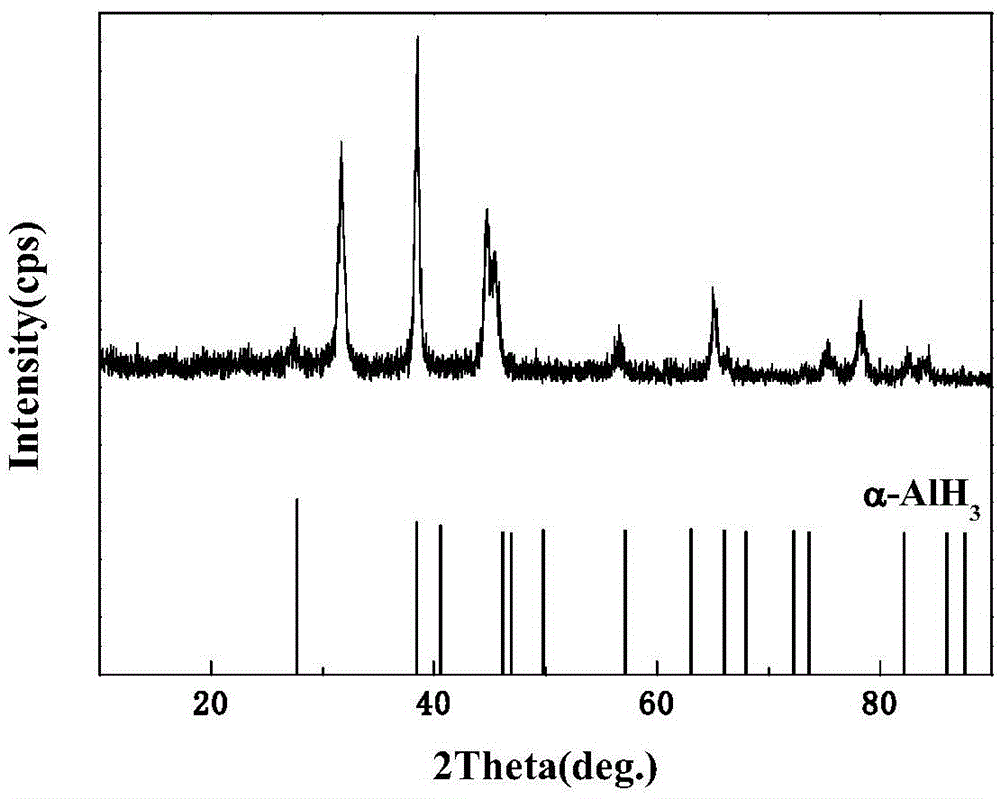

[0020] Specific implementation mode one: a kind of diethyl aluminum hydride and LiBH of this embodiment 4 Preparation of α-AlH by Catalytic Active Aluminum as Catalyst 3 The method, described method is carried out under anhydrous anaerobic condition, and concrete operation steps are as follows:

[0021] 1. Take the activated aluminum powder in the glove box and add it to the autoclave, then add diethyl aluminum hydride and LiBH 4 ;

[0022] 2. Pour 10-15MPa of H into the autoclave of step 1. 2 , and then react at 100-150°C for 5-14 hours;

[0023] 3. After washing the sample obtained in step 2 with anhydrous toluene and anhydrous hexane once, dry it in vacuum for 2 hours to obtain the α-AlH 3 ;

[0024] Among them, aluminum powder, LiBH 4 The mass-volume ratio of diethylaluminum hydride and diethylaluminum hydride is 1g: (1-3) g: (5-15) mL.

[0025] The activated aluminum powder described in this embodiment is obtained by ball milling in a glove box.

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment is different from Embodiment 1 in that: the reaction is carried out at 110-150° C. for 5-14 hours. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Embodiment 3: This embodiment is different from Embodiment 1 in that: the reaction is carried out at 120-150° C. for 5-12 hours. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com