Preparation method of doping modified vanadium dioxide powder with lower phase transition temperature

A phase transition temperature, vanadium dioxide technology, applied in vanadium oxide, chemical instruments and methods, tungsten compounds, etc., can solve problems such as difficult preparation, and achieve the effect of low cost and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: Nano VO 2 preparation of

[0023] V 2 o 5 +H 2 SO 4 +Red→2VOSO 4 +H 2 o

[0024] VOSO 4 +2KOH→VO 2 +K 2 SO 4

[0025] Among them, Red is SO 2 , NaBH 4 , one or more of reducing agents such as hydrazine, hydroxylamine, oxalic acid, formic acid, formaldehyde, methanol, ethanol, etc. In this example, SO 2 as an example.

[0026] Mix 1.8g vanadium pentoxide, 3.0~5.0ml concentrated sulfuric acid and 4–8ml deionized water evenly, heat in a water bath for 20-60 minutes, add water to dilute to 40-50ml. Under the condition of stirring, the newly produced sulfur dioxide is continuously introduced until the suspension of vanadium pentoxide in the acidic medium is completely reduced to blue VO 2+ solution.

[0027] After the reaction is completed, ventilate to drive out the residual vanadium dioxide in the solution. Then slowly drop KOH solution or ammonia solution to adjust the pH value to 4-6. At this time, a brown-green precipitate formed.

[00...

Embodiment 2W

[0029] The nanometer VO of embodiment 2W doping modification 2 preparation of

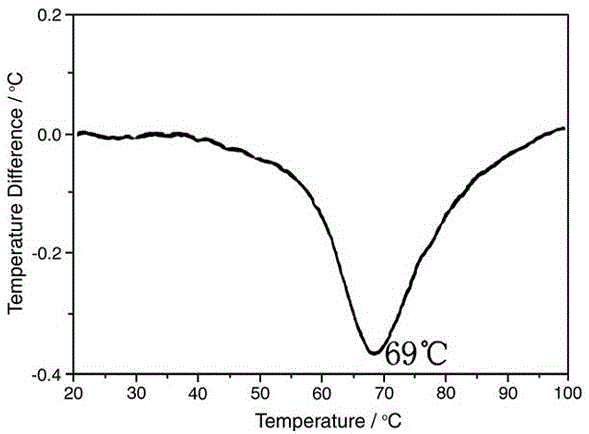

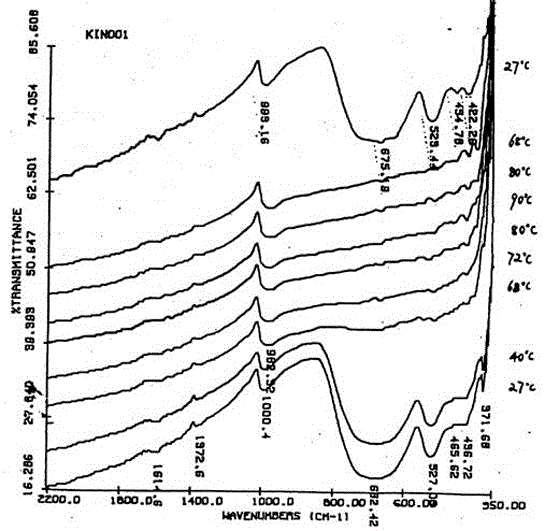

[0030] Obtain blue VO as in embodiment 1 2+ solution, add WO to the system 3 , or soluble tungstate, where W=1~7%, control pH4~6, mix W and VO 2+ Total precipitation. The co-precipitated product is annealed for 6-9h under the condition of 600-900h to obtain W-doped nano-VO 2 Powder. The XPS energy spectrum characterization of the nanomaterials confirmed that the absorption peak at 516.2eV in the spectrum is assigned to V 2p3 / 2 , and V is +4 valence; the absorption peak at 35.30eV is attributed to W 4f7 / 2 (W is +6 valence), thus indicating that W atoms are doped in VO 2 middle. For the corresponding TEM characterization see Figure 4 According to the differential thermal analysis of the nanomaterial, its phase transition point has been reduced to 58°C, which is 10 degrees lower than that of the aforementioned materials.

[0031] Change the tungsten source into corresponding MoO in embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com