Continuous aerobic composting device and disposal method for dead livestock and poultry on livestock and poultry farm

A technology of aerobic composting and treatment method, applied in fertilization device, biological organic part treatment, organic fertilizer and other directions, can solve the problems of insufficient stirring of materials, affecting air quality, low degree of automation, etc., and achieve full stirring and full air distribution. Uniform, highly automated results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

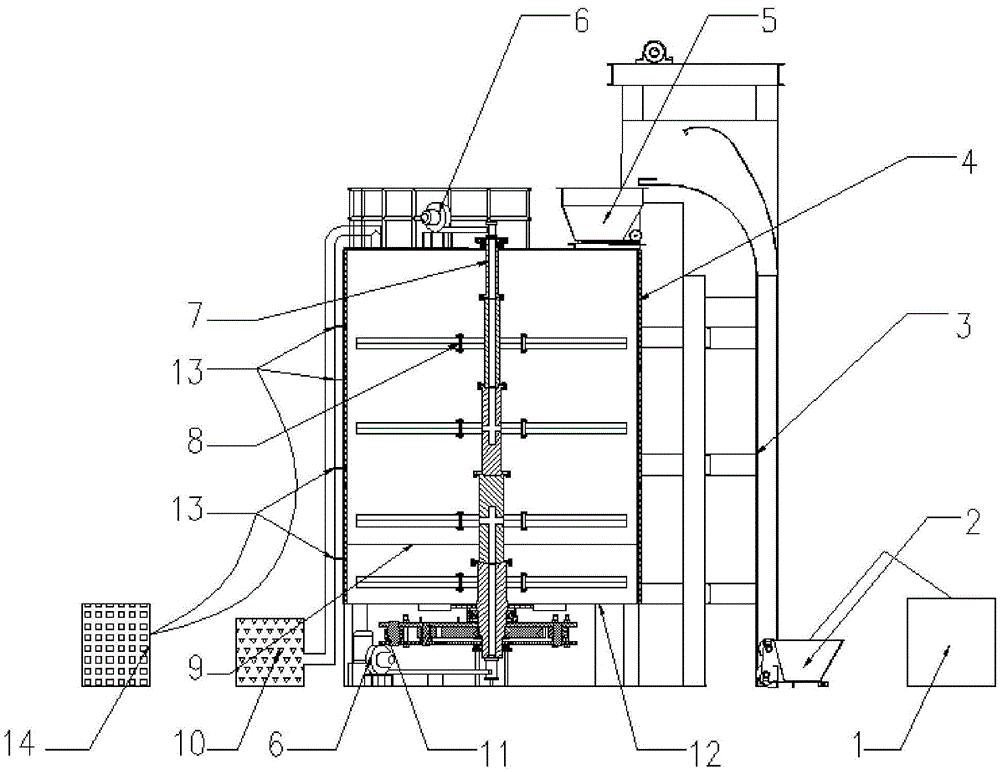

[0042] Such as figure 1 As shown, a continuous aerobic composting device for dead livestock and poultry in a livestock and poultry farm in this embodiment includes a crushing device 1 , a hollow fermentation tank body 4 , a spindle drive device 11 , a deodorizing device 10 and a control system 14 . The fermentation tank body 4 is a double-layer structure, and the insulation material is filled between the two layers. The insulation material is polyurethane rigid foam, rock wool, perlite or other similar materials with thermal insulation effect. In this embodiment, polyurethane rigid foam is used. quality foam, insulation material can reduce the heat loss in the fermenter body 4, help to maintain the temperature in the fermenter body 4, the volume of the fermenter body 4 is 100 cubic meters, diameter and height are 5 meters, the top of the fermenter body 4 A feed port 5 is provided, a discharge port 12 is provided at the bottom, and a drain plate 9 is provided at the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com