Method for separating and purifying NONA

A technology of nonanitroterphenyl and purification method, applied in the field of compound separation, can solve the problems of long time-consuming, long time-consuming, complicated operation and the like of nitrobenzene, and achieve the effects of short experimental period, time saving and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

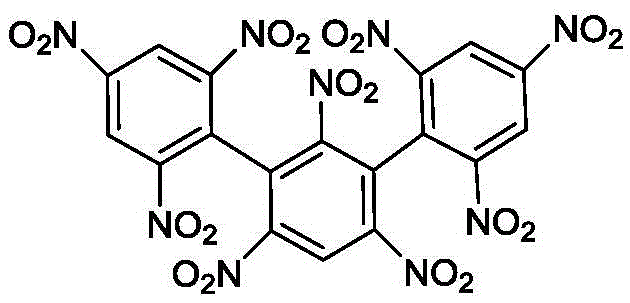

[0014] At room temperature, add 400ml of chloroform to the reaction mother liquor of 100ml 2,2',2",4,4',4",6,6',6"-nonanitroterphenyl, a brownish black solid is precipitated, Filter, wash the filter cake with 100ml of toluene for 4 times until the filtrate is colorless, heat filter, dissolve the filter cake in 100ml of acetone, add 10g of activated carbon, 10g of diatomaceous earth for decolorization, filter, and evaporate the filtrate to obtain 2,2' , 2", 4, 4', 4", 6, 6', 6"-nonanitroterphenyl, yield 16%, purity 98.00% (HPLC).

[0015] Structure Identification:

[0016] 1 HNMR (acetone-d6, 500MHz): 9.346 (s, 4H), 9.457 (s, 1H);

[0017] IR(KBr)γ: 3444, 3108, 1608, 1543, 1340, 1175, 1128, 1076, 921, 824, 726, 541cm -1 .

[0018] The above structural identification data confirm that the substance obtained in this step is 2,2′,2″,4,4′,4″,6,6′,6″-nonanitroterphenyl.

Embodiment 2

[0020] At room temperature, add 500ml of chloroform to the reaction mother liquor of 100ml 2,2',2",4,4',4",6,6',6"-nonanitroterphenyl, a brown-black solid is precipitated, Filter, wash the filter cake with 100ml of toluene for 5 times until the filtrate is colorless, heat filter, dissolve the filter cake in 100ml of acetone, add 10g of activated carbon, 10g of diatomaceous earth for decolorization, filter, evaporate the filtrate to dryness to obtain 2,2' , 2", 4, 4', 4", 6, 6', 6"-nonanitroterphenyl, yield 16%, purity 98.00% (HPLC).

Embodiment 3

[0022] At room temperature, add 300ml of chloroform to the reaction mother liquor of 100ml 2,2',2",4,4',4",6,6',6"-nonanitroterphenyl, and a brown-black solid is precipitated. Filter, wash the filter cake with 100ml of toluene for 4 times until the filtrate is colorless, heat filter, dissolve the filter cake in 100ml of acetone, add 10g of activated carbon, 10g of diatomaceous earth for decolorization, filter, and evaporate the filtrate to obtain 2,2' , 2″, 4, 4′, 4″, 6, 6′, 6″-nonanitroterphenyl, yield 12%, purity 97.00% (HPLC).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com