Polyester coating and preparation method thereof

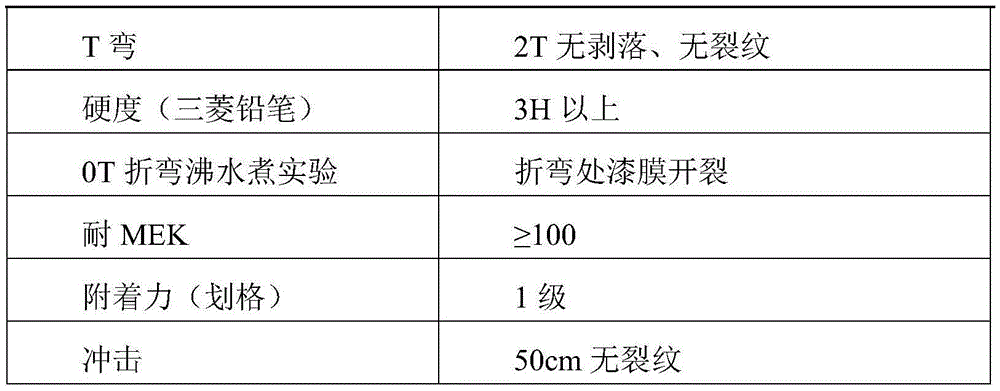

A polyester coating and di-polyester technology, applied in the coating field, can solve the problems of incomplete curing, poor flexibility, poor performance of paint film peeling, etc., and achieve the effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

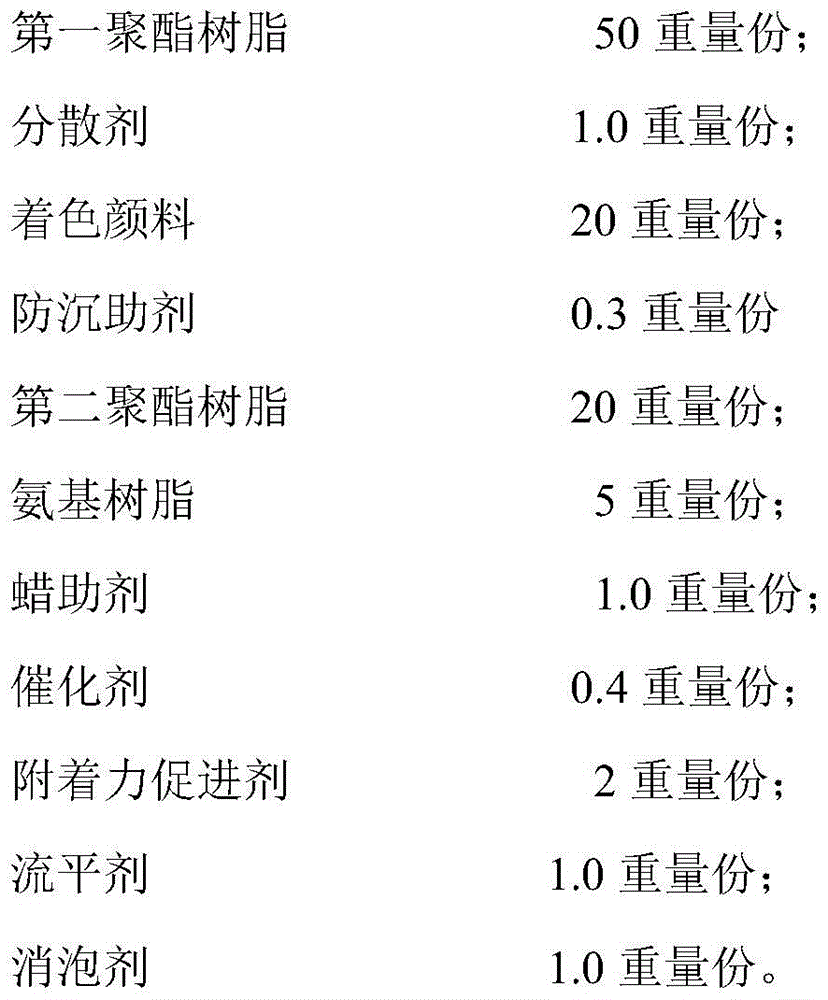

[0059] A preparation method of polyester coating includes the following steps:

[0060] Step 1: Sanding 35.0 parts by weight of the first polyester resin, 1.0 parts by weight of dispersant, 30.0 parts by weight of coloring pigments, 0.3 parts by weight of anti-settling additives, and 10.0 parts by weight of S-150 solvent oil to obtain slurry;

[0061] Step 2: Add 10.0 parts by weight of second polyester resin, 5.0 parts by weight of amino resin, 0.4 parts by weight of catalyst, 2.0 parts by weight of adhesion promoter, 1.0 parts by weight of leveling agent, and 1.0 parts by weight of defoamer into the slurry Parts, 2.0 parts by weight of matting agent, 1.0 parts by weight of wax additives, and 10.0 parts by weight of S-150 solvent naphtha, and mixed to obtain the polyester coating.

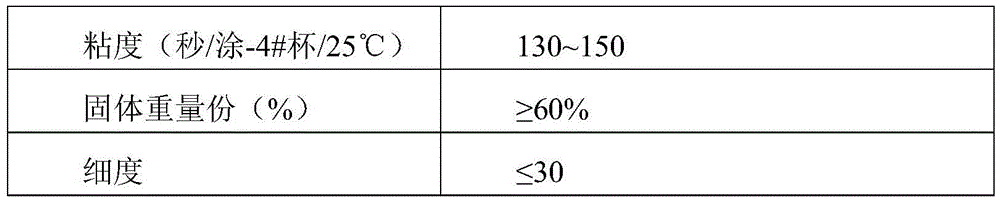

[0062] In the step 2, the viscosity of the polyester coating is adjusted to: 130-150 seconds, measured with a Tu-4# cup at 25°C (130-150 seconds / Tu-4# cup / 25°C); or adjusted to 500- 600mPa.s.

[0063] Th...

Embodiment 2

[0069] A preparation method of polyester coating includes the following steps:

[0070] Step 1: Mix 35 parts by weight of the first polyester resin, 1.0 parts by weight of dispersant, 30 parts by weight of coloring pigments, 0.3 parts by weight of anti-settling aids, and 10.0 parts by weight of S-150 solvent oil, and sand to obtain a slurry;

[0071] Step 2: Add 10.0 parts by weight of second polyester resin, 3.0 parts by weight of amino resin, 0.4 parts by weight of catalyst, 2.0 parts by weight of adhesion promoter, 1.0 parts by weight of leveling agent, and 1.0 parts by weight of defoamer into the slurry Parts, 2.0 parts by weight of matting agent, 1.0 parts by weight of wax additives, and 10.0 parts by weight of S-150 solvent naphtha, and mixed to obtain the polyester coating.

[0072] In the step 2, the viscosity of the polyester coating is adjusted to: 130-150 seconds, measured with a Tu-4# cup at 25°C (130-150 seconds / Tu-4# cup / 25°C); or adjusted to 500- 600mPa.s.

[0073] The...

Embodiment 3

[0081] A preparation method of polyester coating includes the following steps:

[0082] Step 1: Mix 35.0 parts by weight of the first polyester resin, 1.0 parts by weight of the dispersant, 40.0 parts by weight of the coloring pigment, 0.3 parts by weight of the anti-settling aid, and appropriate amount of ethylene glycol butyl ether, and sand to obtain a slurry;

[0083] Step 2: Add 10.0 parts by weight of second polyester resin, 5.0 parts by weight of amino resin, 0.4 parts by weight of catalyst, 2.0 parts by weight of adhesion promoter, 1.0 parts by weight of leveling agent, and 1.0 parts by weight of defoamer into the slurry Parts, 2.0 parts by weight of matting agent, 1.0 parts by weight of wax additives, and 10.0 parts by weight of S-150 solvent naphtha, and mixed to obtain the polyester coating.

[0084] In the step 2, the viscosity of the polyester coating is adjusted to: 130-150 seconds, measured with a Tu-4# cup at 25°C (130-150 seconds / Tu-4# cup / 25°C); or adjusted to 500- ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com