Method for producing clean diesel oil and light aromatic hydrocarbons from inferior diesel oil

A technology for low-quality diesel oil and light aromatics, which is applied in the fields of hydrocarbon oil treatment products, petroleum industry, and hydrocarbon oil treatment. It can solve the problems of low separation efficiency in the extraction process, poor selectivity of aromatics, and harsh reaction conditions, and achieve low reaction pressure. , less loss of aromatics and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

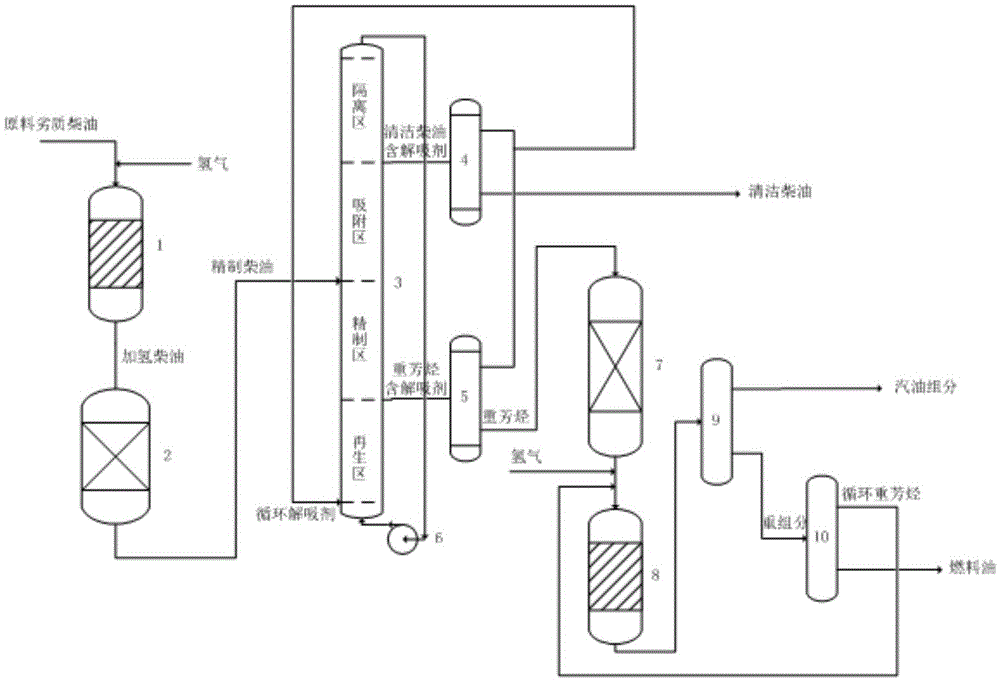

Method used

Image

Examples

Embodiment 1

[0040] (1) The catalyst used in the hydrotreating of raw diesel oil is Ni / Mo-Al 2 o 3 Commercial catalyst FH-98, the loading capacity of the catalyst in the hydrofining reactor is 200ml, the reaction temperature is 380°C, the reaction pressure is 6MPa, and the reaction space velocity is 1.0h -1 , the properties of the obtained hydrogenated diesel are shown in Table 2.

[0041] (2) Hydrogenated diesel pretreatment adsorption, the pretreatment adsorbent is industrial X molecular sieve, the specific surface area is 490m 2 / g, silicon aluminum ratio SiO 2 / Al 2 o 3 =2.5, the loading capacity of the adsorbent is 400ml, the adsorption temperature is 30°C, the pressure is 0.8MPa, and the adsorption space velocity is 0.5h -1 .

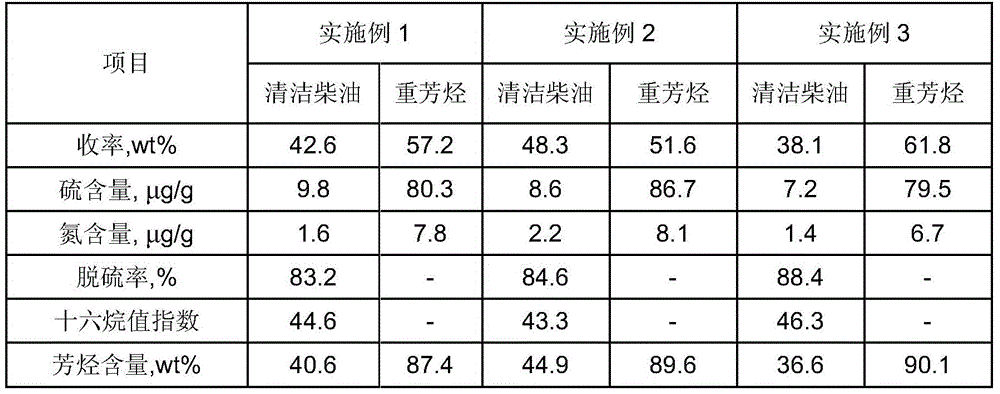

[0042] (3) The simulated moving bed adsorption device contains 12 adsorption beds, which are divided into adsorption area, isolation area, regeneration area and refining area. Silicon, the content of MgO is 1.98wt%, the rest is SiO 2 , the specific sur...

Embodiment 2

[0045] (1) Hydrofining of raw diesel is the same as in Example 1, and the properties of the obtained hydrogenated diesel are shown in Table 2.

[0046] (2) The adsorbent used for hydrogenated diesel pretreatment adsorption is clay, and other conditions are the same as in Example 1.

[0047] (3) The adsorption temperature of the simulated moving bed was 75°C, the valve switching time was 320-360s, the mass ratio of desorbent to raw material feed was 1.8:1, other conditions were the same as in Example 1, and the composition of each component was shown in Table 3.

[0048] (4) Heavy aromatics and hydrogen are mixed into the lightening reactor, the content of the catalyst Pt used is 0.15%, the reaction pressure is 3.0MPa, the reaction temperature is 370~380°C, other conditions are the same as in Example 1, and the lightening The product composition is shown in Table 4.

Embodiment 3

[0050] (1) Hydrofining of raw diesel is the same as in Example 1, and the properties of the obtained hydrogenated diesel are shown in Table 2.

[0051] (2) The adsorbent used in the pretreatment of hydrogenated diesel oil is alumina, and other conditions are the same as in Example 1.

[0052] (3) The adsorption temperature of the simulated moving bed was 80°C, the valve switching time was 300-340s, the mass ratio of desorbent to raw material feed was 1.6:1, other conditions were the same as in Example 1, and the composition of each component was shown in Table 3.

[0053] (4) Heavy aromatics and hydrogen are mixed into the lightening reactor, the catalyst Pt content used is 0.13%, the reaction pressure is 3.2MPa, the reaction temperature is 370~380°C, other conditions are the same as in Example 1, and the lightening The product composition is shown in Table 4.

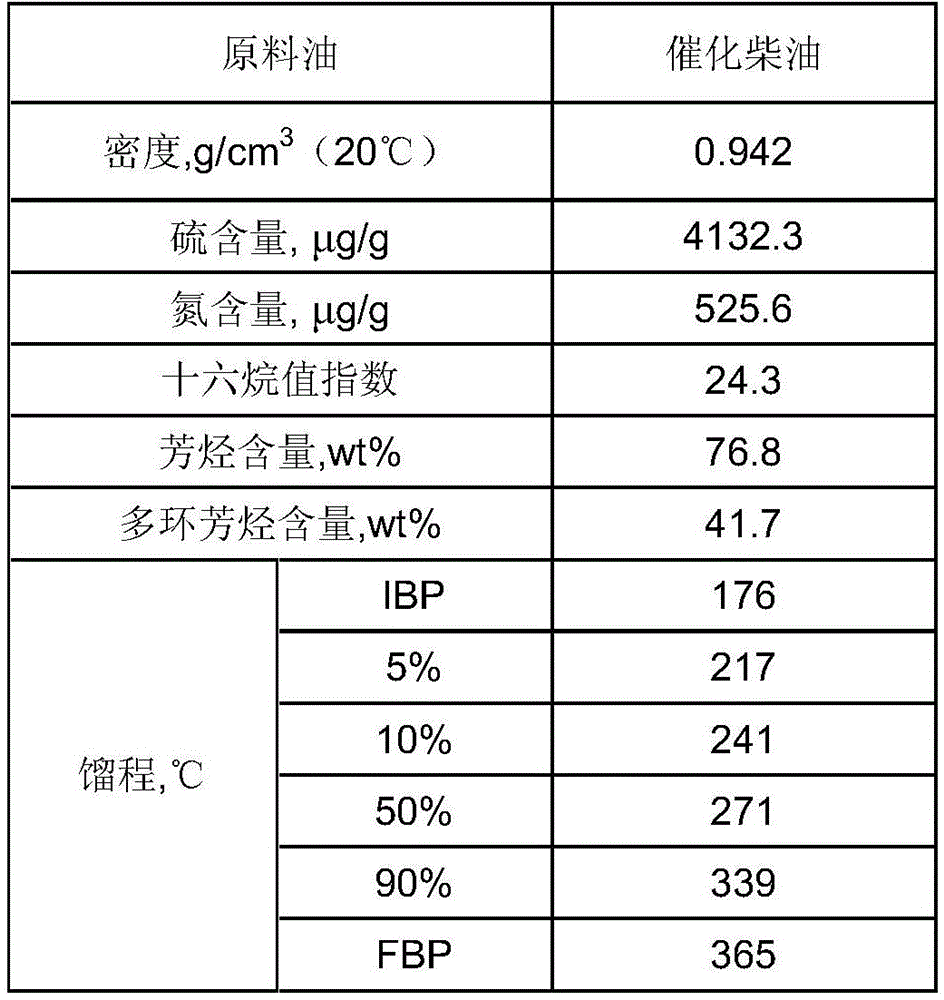

[0054] Table 1 Data sheet of raw material diesel oil properties

[0055]

[0056] Table 2 Diesel properties dat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com