Lead dross treatment method

A treatment method, the technology of lead scum, applied in the field of metal processing, can solve the problems of low crude lead output rate, complex process, high energy consumption, etc., and achieve the effects of good environmental protection effect, wide material adaptability, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

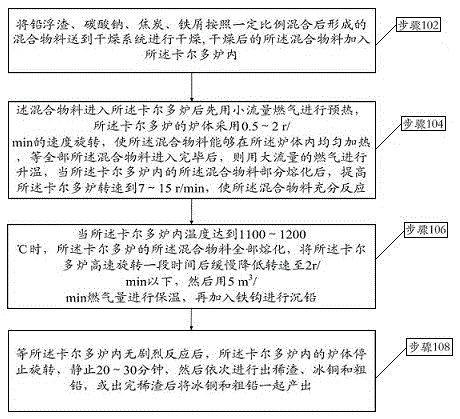

Image

Examples

Embodiment Construction

[0017] Functional Overview

[0018] Considering the problems of low crude lead yield, high energy consumption and complex process in existing lead scum treatment methods, a lead scum treatment method was proposed to solve related problems.

[0019] Embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments of the present invention and the technical features in the embodiments can be combined with each other, all within the protection scope of the present invention. In addition, for ease of description, step numbers are used hereinafter, but this should not be construed as a limitation to the present invention. In addition, although the various steps described in the following methods show a logical order in the flowchart, in some cases In this case, the steps shown or described may be performed in an order different from that herein.

[0020] method embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com