PTC parallel flow heater

A heater and parallel flow technology, which is applied in the field of PTC parallel flow heaters, can solve the problems that the gap between the surface and the PTC element cannot fit well, the heat exchange efficiency decreases, and the thermal conductivity is small, so as to achieve easy industrial production and stable temperature , High heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0047] In order to illustrate the beneficial effects of the PTC parallel flow heater of the present invention, the inventors of the present invention obtained the following relevant conclusions by means of experiments.

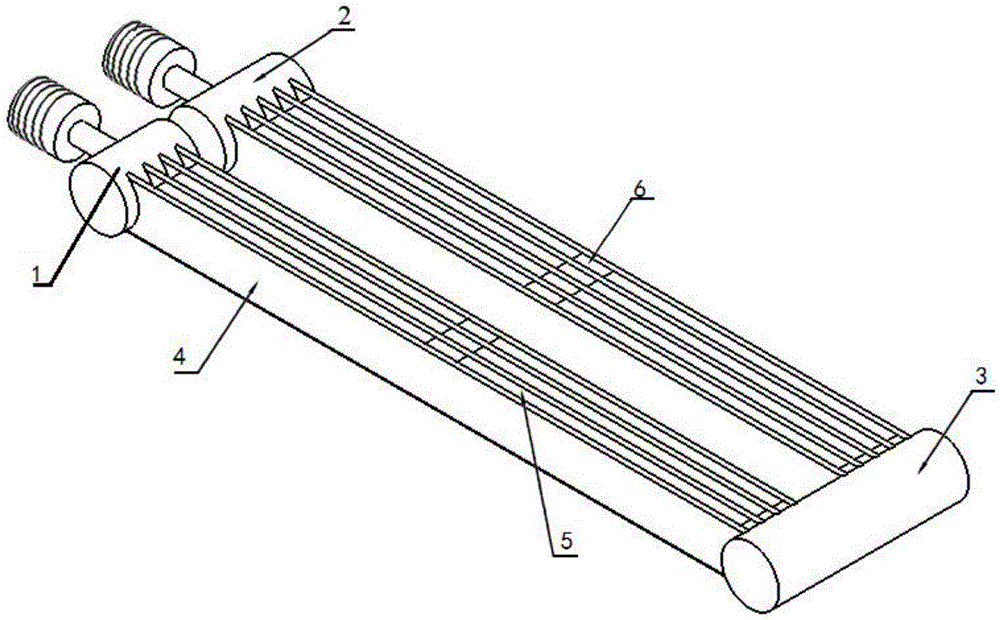

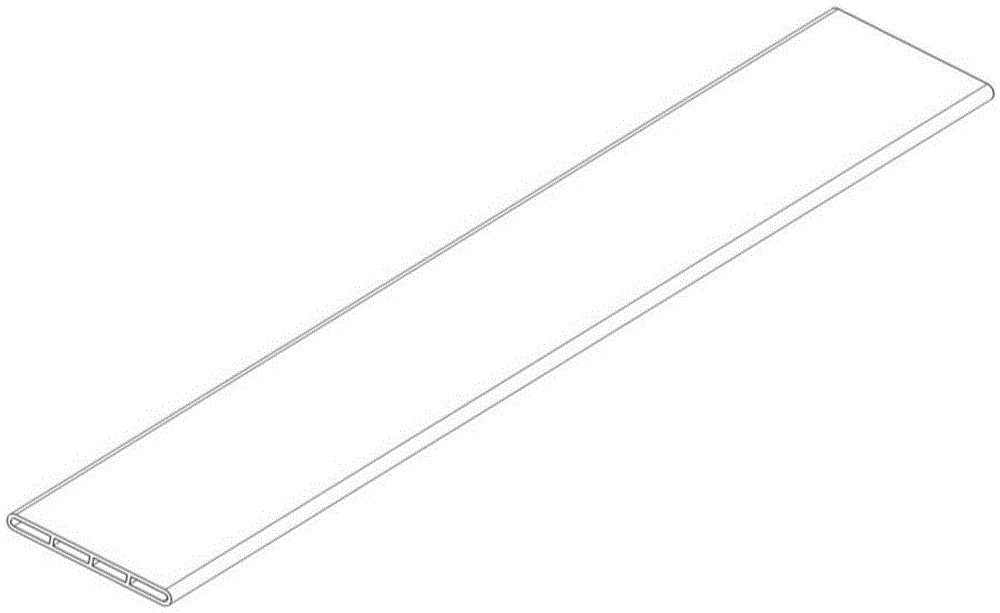

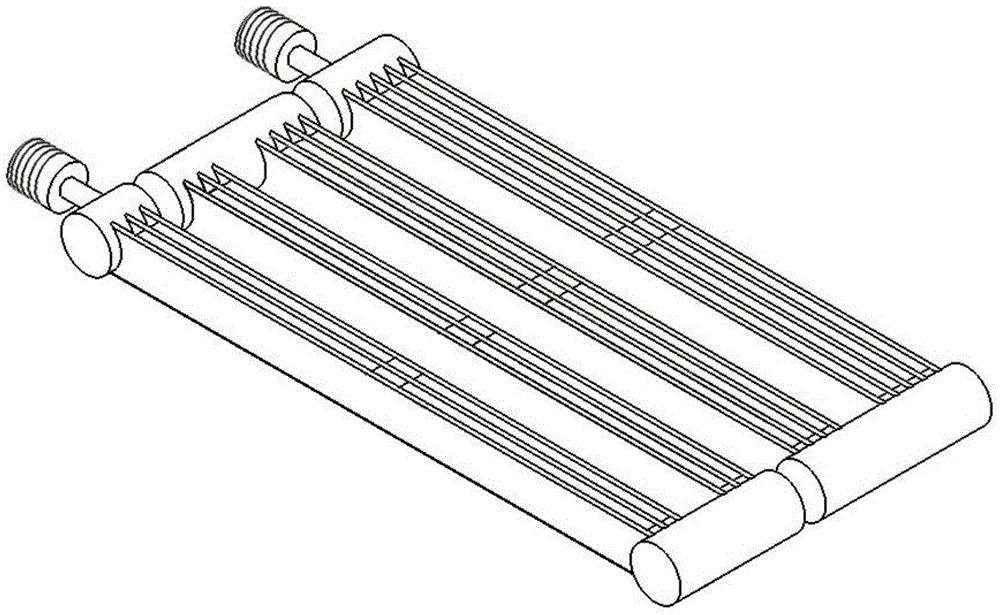

[0048] Test conditions: using such as figure 1 The heater body of the structure shown, and adopts such as Figure 5 The structural dimensions of the main body of the heater shown, the dimensions of the flat heat exchange tubes and their array layout refer to Figure 6 , Figure 6 for Figure 5 The A-A cross-sectional dimension drawing, Figure 5 and Figure 6 The unit of each dimension is mm, the flat heat exchange tube and the PTC element are fixed and compressed by screws, and the inlet and outlet ports are standard 4-point interface; the size of the PTC element is 100mm×21mm×5mm, a total of 14 pieces, each with a voltage of 220V and a power of 160W ; 220V small circulating water pump, pump head 8m, maximum flow 60L / min.

[0049] Comparative test piece...

Embodiment approach 2

[0053] In the floor low-temperature radiant heating system and radiator heating mode, the heating heat source is hot water at 55°C / 45°C, and the wall-hung boiler mainly uses natural gas, liquefied petroleum gas, city gas and electricity as energy sources. The patented PTC parallel heating system of the invention Flow liquid heater, high heat exchange efficiency, can replace wall-hung boilers that use electricity as energy consumption in floor low-temperature radiant heating systems (with electric heating tubes as the main method), and can achieve certain energy-saving benefits.

Embodiment approach 3

[0055] For instant electric water heaters, because of its excessive power (minimum power 4500W), many potential safety hazards will be caused during use. Using the PTC liquid heater of the present invention, the separation of water and electricity is really realized, and the power is relatively small (about 2200W Left and right), the water flow resistance is small, and the heat exchange efficiency is high, so it is an ideal instant liquid heater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com