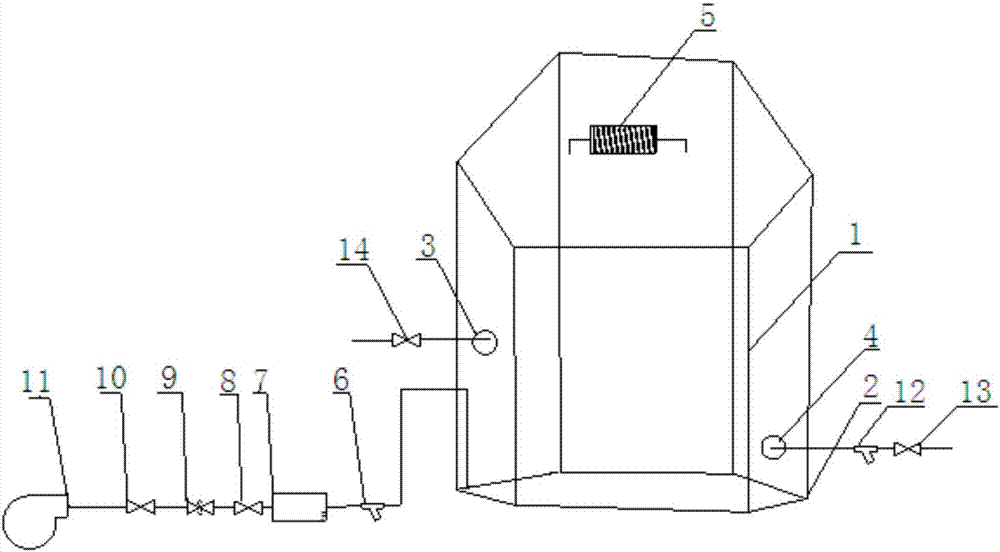

A device and method for homogenizing heat flux density on the wall surface of a solar heat absorber

A technology of solar heat absorption and heat flux, which is applied in the direction of solar thermal devices, solar thermal power generation, heating devices, etc., can solve the problem of high thermal stress on the heat absorbing pipe surface of the heat absorber, uneven distribution of heat flux density field, and poor heat absorption pipe surface Ineffectiveness and other problems, to achieve the effect of less investment and maintenance costs, improve light-to-heat conversion efficiency, and reduce convective heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

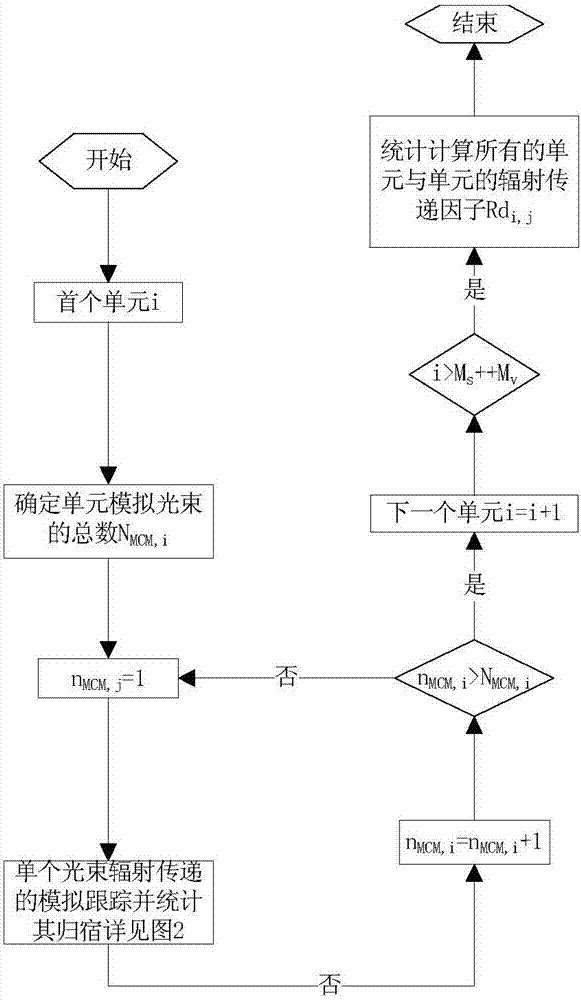

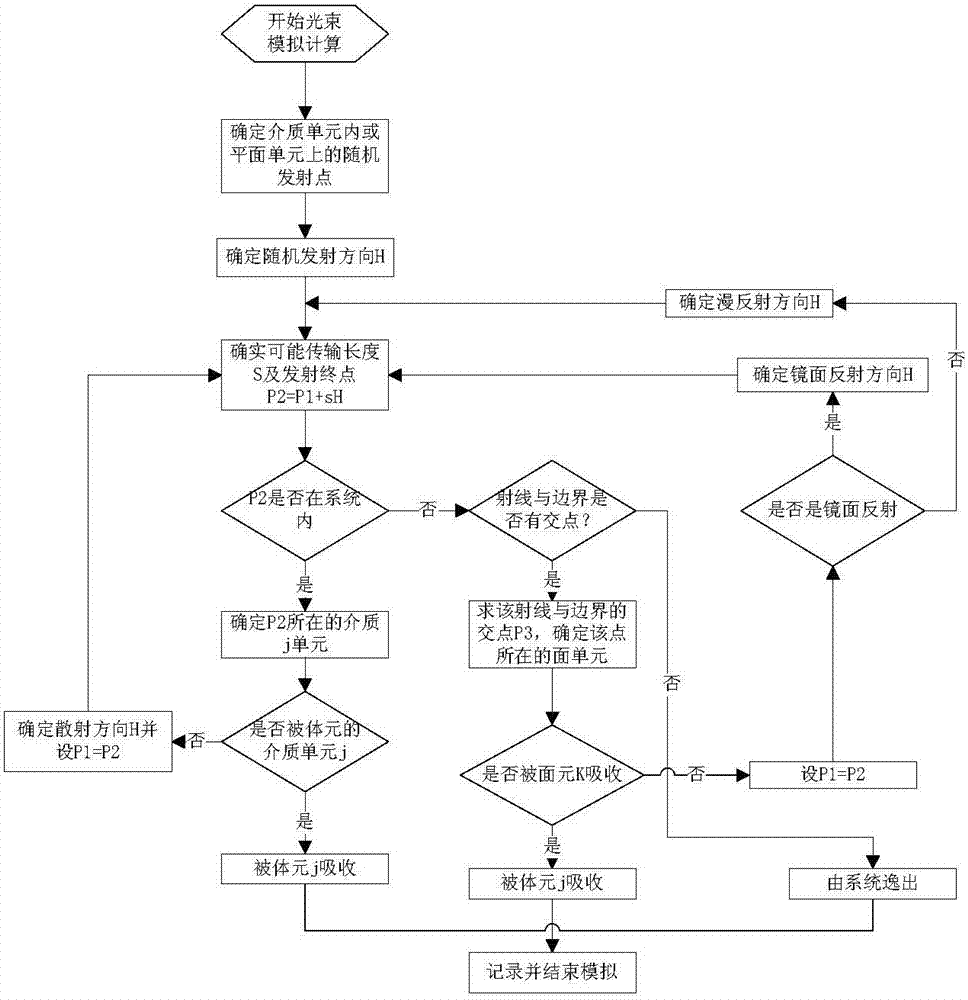

Method used

Image

Examples

Embodiment

[0062] Fill the cube cavity of 4m×4m×4m with a particle size of 0.08-50um and a particle number density of 1×10 7 -1×10 16 / m 3 Carbon particles (refractive index of carbon particles 1.93 (1-0.53i)) mixed media. In order to simplify the calculation, two-dimensional Monte Carlo calculation is adopted, Figure 4 To simplify the calculation diagram, Figure 5 is the known heat flux distribution at the opening, Figure 6-9 It is the wall temperature distribution diagram when adding different particle sizes and different number densities into the cavity. From Figure 6-9 It can be seen that when the aerosol is added, the temperature of the high temperature area in the middle of the wall will tend to be consistent with the increase of the number density. The temperature uniformity of the wall is significantly improved by the absorption, scattering and radiation of the particle phase in the aerosol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com