Quinoa germ flour-containing bread frozen dough and preparation method thereof

A technology for freezing dough and germ powder, which is used in dough processing, baking, and baked goods with modified ingredients, etc., can solve problems such as the decline of the fermentation ability of air-holding yeast cells, affecting the appearance and taste of bread, and the small size of bread, etc. Achieve the effect of improving hair swelling, increasing nutrient content and enhancing aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

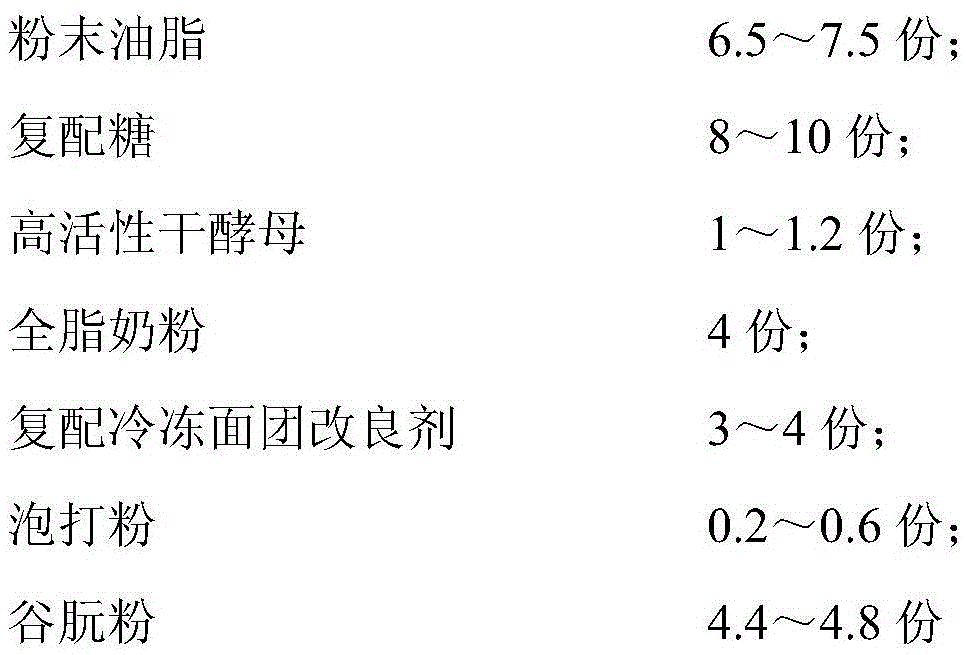

[0058] A bread frozen dough containing quinoa germ powder, calculated in parts by weight, its raw material composition and content are as follows:

[0059]

[0060] The compound sugar, calculated by weight ratio, is formed by compounding trehalose: sucrose: maltoligosaccharide: xylitol at a ratio of 0.8:1:1.3:0.08;

[0061] The specifications of the high-gluten wheat flour meet the national standard GB / T8607-1988;

[0062] The specification of the powdered grease complies with GB17402-2003;

[0063] The specification of the compound frozen dough improver complies with GB2760-2014;

[0064] The compound frozen dough improver is formed by mixing diacetyl tartaric acid mono-diglyceride, ice structural protein, ascorbic acid, and glutamine transaminase. Calculated by weight ratio, diacetyl tartaric acid mono-diglyceride: ice structural protein: ascorbic acid : Transglutaminase is 0.8:0.2:0.0125:1.4;

[0065] The specification of the high active dry yeast complies with GB / T2088...

Embodiment 2

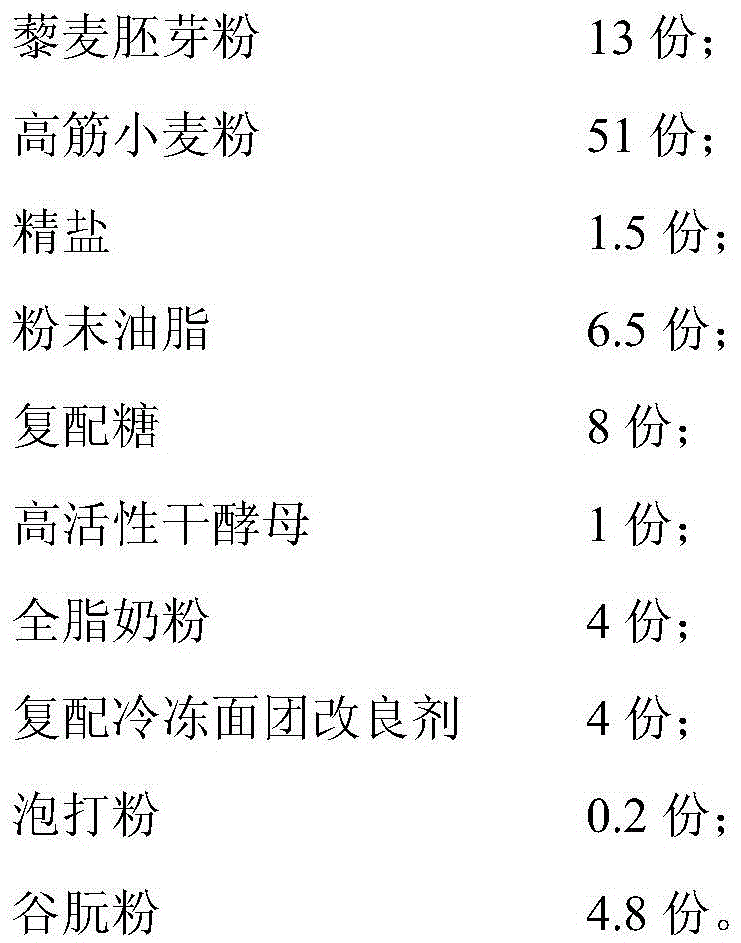

[0100] A bread frozen dough containing quinoa germ powder, calculated in parts by weight, its raw material composition and content are as follows:

[0101]

[0102] The compound sugar, calculated by weight ratio, is formed by compounding trehalose: sucrose: maltoligosaccharide: xylitol at a ratio of 0.8:1:1.3:0.08;

[0103] The specifications of the high-gluten wheat flour meet the national standard GB / T8607-1988;

[0104] The specification of the powdered grease complies with GB17402-2003;

[0105] The specification of the compound frozen dough improver complies with GB2760-2014;

[0106] The compound frozen dough improver is formed by mixing diacetyl tartaric acid mono-diglyceride, ice structural protein, ascorbic acid, and glutamine transaminase. Calculated by weight ratio, diacetyl tartaric acid mono-diglyceride: ice structural protein: ascorbic acid : Transglutaminase is 0.8:0.2:0.0125:1.4;

[0107] The specification of the high active dry yeast complies with GB / T20...

Embodiment 3

[0136] A quinoa germ flour bread frozen dough, calculated in parts by weight, its raw material composition and content are as follows:

[0137]

[0138] The compound sugar, calculated by weight ratio, is formed by compounding trehalose: sucrose: maltoligosaccharide: xylitol at a ratio of 0.8:1:1.3:0.08;

[0139] The specifications of the high-gluten wheat flour meet the national standard GB / T8607-1988;

[0140] The specification of the powdered grease complies with GB17402-2003;

[0141] The specification of the compound frozen dough improver complies with GB2760-2014;

[0142] The compound frozen dough improver is formed by mixing diacetyl tartaric acid mono-diglyceride, ice structural protein, ascorbic acid, and glutamine transaminase. Calculated by weight ratio, diacetyl tartaric acid mono-diglyceride: ice structural protein: ascorbic acid : Transglutaminase is 0.8:0.2:0.0125:1.4;

[0143] The specification of the high active dry yeast complies with GB / T20886;

[0144]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com