Ethylene tetrapolymerization catalyst composition and ethylene tetrapolymerization method

A technology for tetramerization and composition of ethylene, which is applied in the directions of hydrocarbons, hydrocarbons, chemical instruments and methods, can solve the problems of high cost, high production cost, harsh process requirements, etc., and achieves high polymerization activity and reaction. Triggers rapid, repeatable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

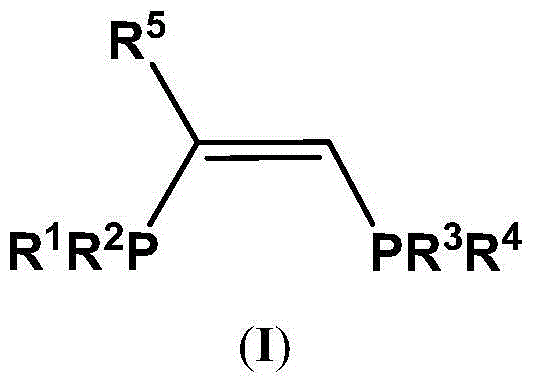

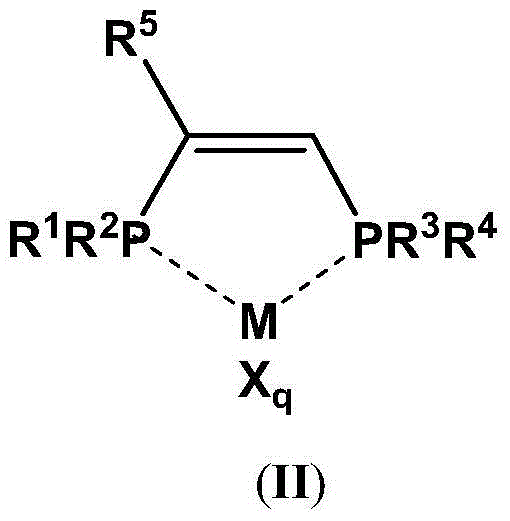

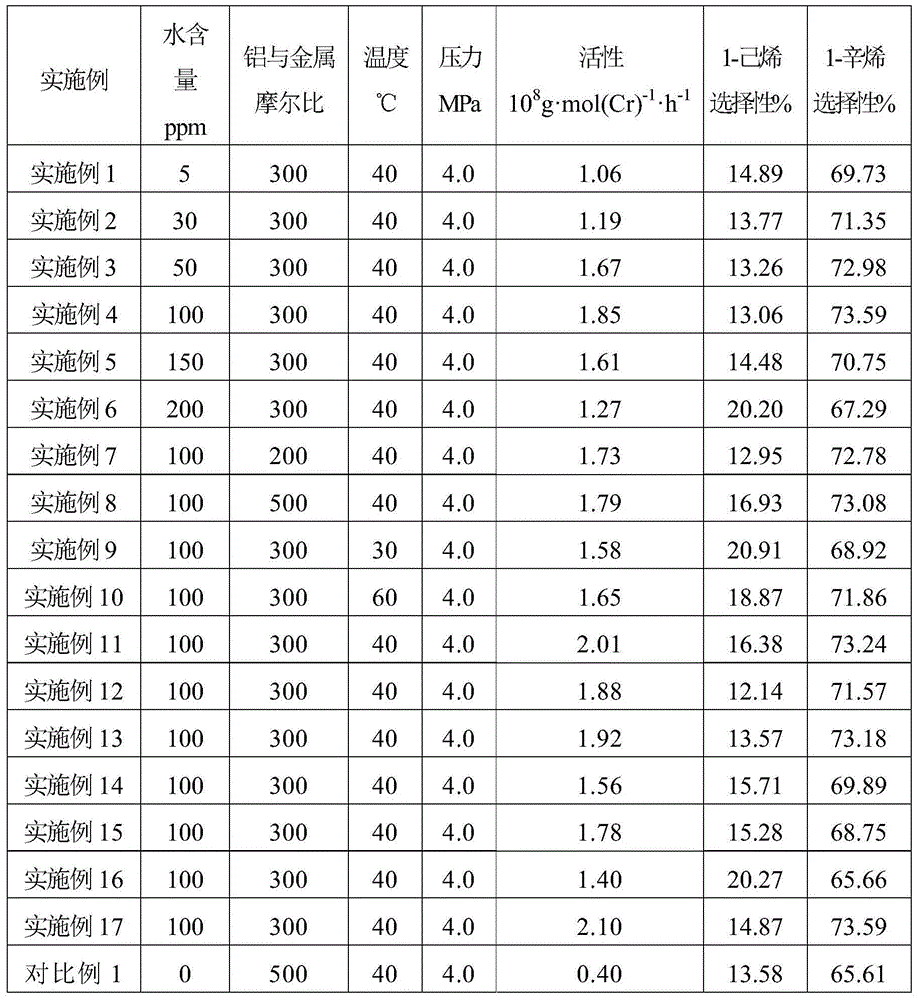

Embodiment 1

[0034] A 300mL stainless steel polymerization kettle is used. Heat the autoclave to 80°C, evacuate and replace with nitrogen several times, then fill with ethylene once, and drop to the set temperature. Add aqueous methylcyclohexane at 40°C, followed by adding 1 μmol bisphosphine ligand (wherein R 1 , R 2 , R 3 and R 4 Both are phenyl, R 5 is methyl), 1 μmol chromium trichloride, quantitative cocatalyst triethylaluminum, the total volume of the mixed solution is 100mL, based on the weight of the organic solvent, the weight content of water is 5ppm, the molar ratio of aluminum to chromium for 300. Control the reaction pressure to 4.0MPa, feed ethylene to carry out ethylene tetramerization reaction. After reacting for 0.5 hour, the temperature of the system was cooled to room temperature, the gas phase product was collected in a gas metering tank, and the liquid phase product was collected in an Erlenmeyer flask, and gas chromatographic analysis was carried out after meter...

Embodiment 2

[0037] Same as Example 1, the difference is that the weight content of water is 30ppm. See Table 1 for the data.

Embodiment 3

[0039] Same as Example 1, the difference is that the weight content of water is 50ppm. See Table 1 for the data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com