A high-speed industrial jet printing control system and method based on fpga technology

A control system, high-speed technology, used in printing, printing devices, etc., can solve problems such as poor printing reliability, satellite ink droplets and trajectory deviation, and ink supply pressure fluctuations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

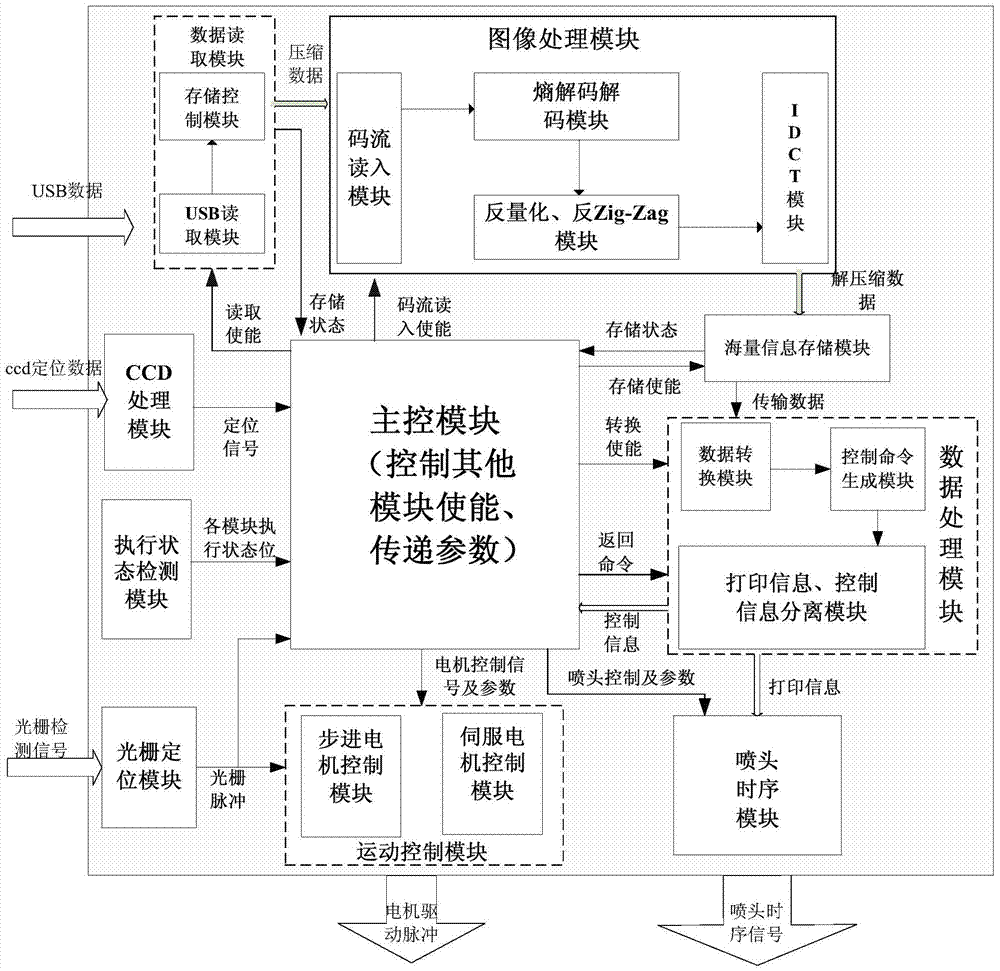

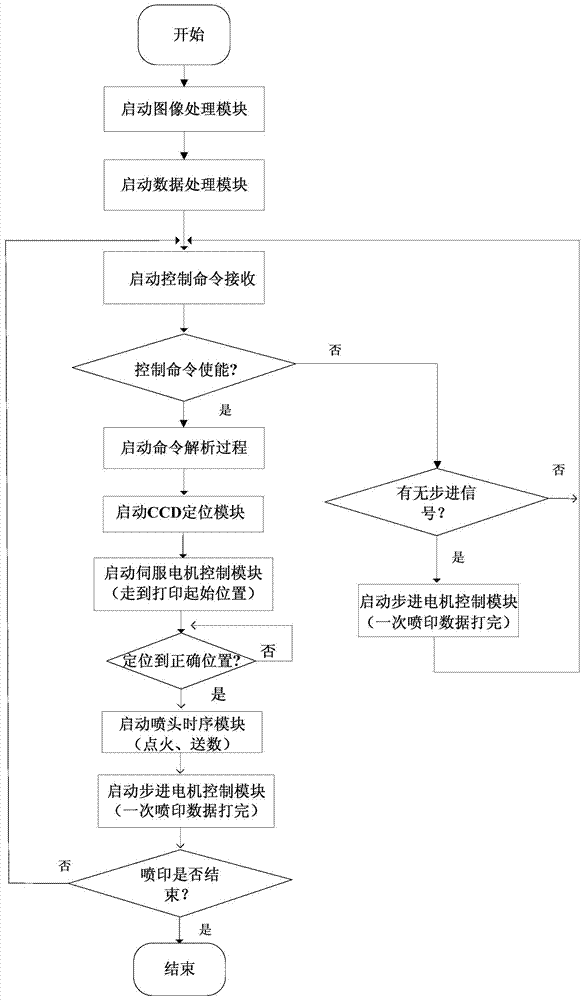

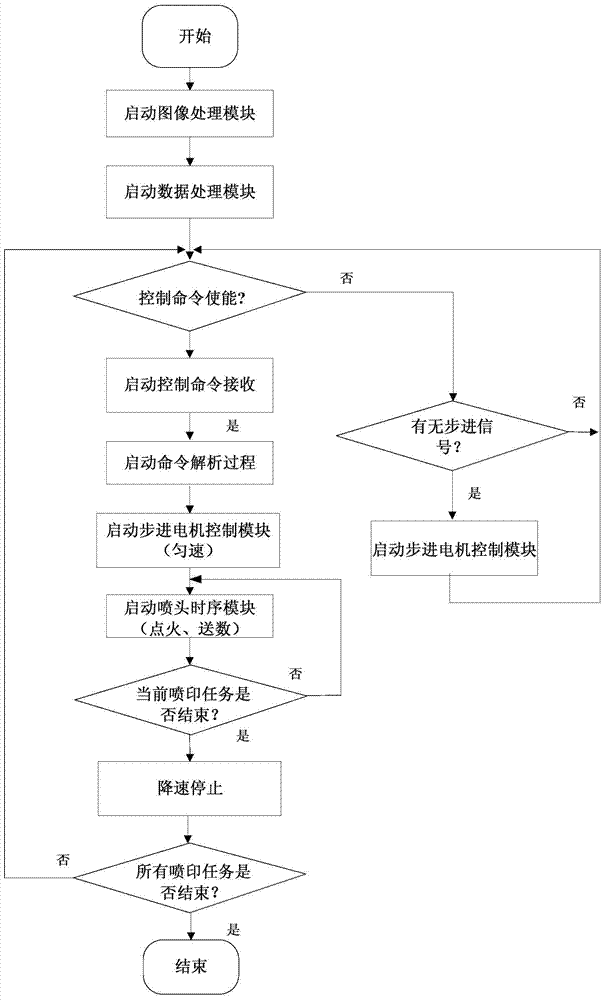

[0078] According to the high-speed inkjet printing process and data processing characteristics of the printed circuit board, the invention divides the FPGA control system into 10 functional modules, and a logic control mechanism is used between each module to coordinate and cooperate to realize high-speed and high-precision inkjet printing. In order to break through the speed bottleneck of massive data printing, the control system integrates the image data processing function to realize fully automatic printing. In order to improve the actual accuracy and speed stability, the internal module of the control system adopts an acceleration and deceleration flexible motion control method.

[0079] according to figure 1 , the control system of the present invention is composed of a main control module, a motion control module, a data reading module,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com