Method for manufacturing ceramic-based composite burners for field of coal chemical industry

A technology of composite materials and manufacturing methods, which is applied in the field of preparation of ceramic matrix composite material burners, can solve problems such as short service life of burners, and achieve the effects of strong adaptability, high hardness and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

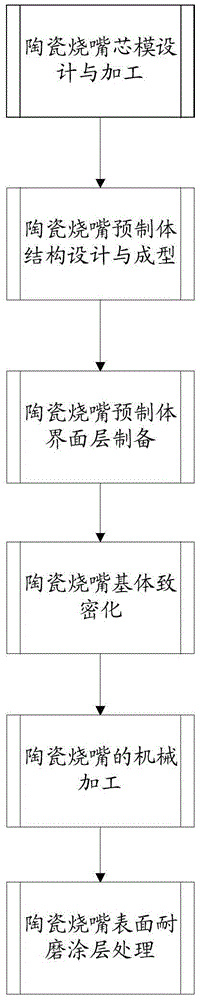

[0023] The C / SiC ceramic matrix composite burner products in the coal chemical industry have the characteristics of complex inner and outer surface shapes, uneven wall thickness, and high requirements for inner surface roughness. The present invention adopts a new process preparation process to manufacture C / SiC ceramic matrix composite material burner products in the field of coal chemical industry. The specific process flow is as follows figure 1 shown.

[0024] The basic steps of the method for manufacturing a C / SiC ceramic matrix composite burner in the field of coal chemical industry are described in detail below:

[0025] ⑴Ceramic burner mandrel design and processing: Based on the design size of the burner product structure, graphite is used as the mandrel material, and the mandrel structure is designed under the premise of ensuring strength. For the convenience of later use, the mandrel adopts a split design structure , whose size is determined by the size of the burne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com