Preparation method of high-tacticity polypropylene

A technology of tacticity and polypropylene is applied in the field of preparation of high tacticity polypropylene to achieve the effects of improving product performance, simple and effective operation, and convenient direct switching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The reactor for preparing high isotactic polypropylene is a steel pressure-resistant reactor with a mechanical stirring device and a temperature control jacket, and the volume of the kettle is 10L. The lid of the reaction kettle is equipped with a gaseous monomer feed port and valve, a catalyst feed port, a pressure gauge and an exhaust pipeline with a pressure controller, and a discharge valve is provided at the bottom of the reactor. Before the reaction, the temperature of the kettle was raised to 100°C, and the kettle was evacuated for 2 hours through the catalyst feed port to remove moisture and air in the kettle, and then the temperature of the kettle was lowered to 20-25°C, and the stirring speed was adjusted to 250 rpm. Add hydrogen to 0.1MPa, add 1.5 kg of polymerization-grade liquid propylene through the gaseous monomer feed port of the kettle cover, and add mixed cocatalysts triethylaluminum (TEA) and trimethylaluminum (TMA) in sequence from the catalyst feed p...

Embodiment 6

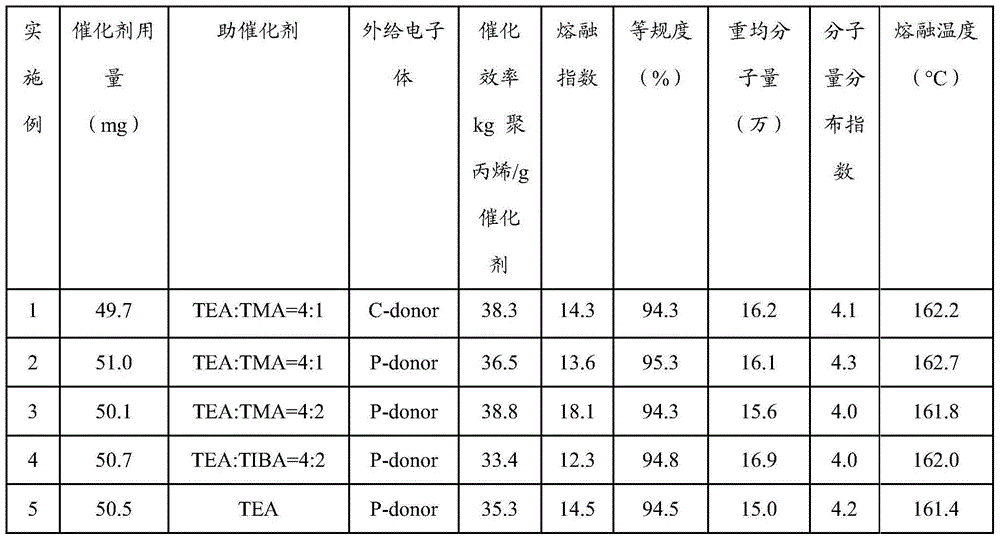

[0026] In Example 6, the amount of the main catalyst is 51.0 mg, and the mixed cocatalyst triethylaluminum (TEA) and trimethylaluminum (TMA) used are in a molar ratio of 4:1 (2M n-heptane solution). Electron donor diisobutyldimethoxysilane (P-donor, 0.5M n-heptane solution) and other operating procedures and polymerization conditions are the same as in Example 1. The catalytic efficiency of the polymerization reaction was 36.5 kg polypropylene / g catalyst. The polymer reactions and test results are listed in Table 1.

Embodiment 7

[0028] In Example 7, the amount of the main catalyst is 50.1 mg, and the mixed cocatalyst triethylaluminum (TEA) and trimethylaluminum (TMA) used are in a molar ratio of 4:2 (2M n-heptane solution). Electron donor diisobutyldimethoxysilane (P-donor, 0.5M n-heptane solution) and other operating procedures and polymerization conditions are the same as in Example 1. The catalytic efficiency of the polymerization reaction was 38.8 kg polypropylene / g catalyst. The polymer reactions and test results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com