Detergent assistant with fumaric acid serving as main synthesis raw material and preparation method of detergent assistant

A technology of builder and fumaric acid, which is applied in the direction of washing compositions containing organic compounds, soap detergents and other compounding agents, organic washing compositions, etc., can solve the problem that the washing performance cannot be further improved, affecting the washing effect, Low reactivity and other problems, to achieve the effect of easy polymerization reaction, reduced reaction time and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

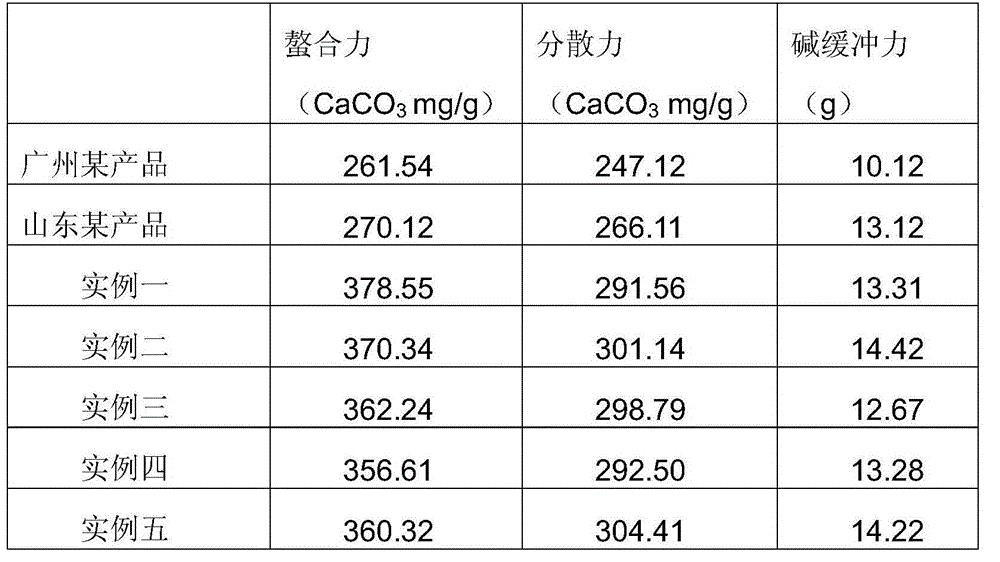

Examples

Embodiment 1

[0024] Add 2kg of deionized water and 6kg of fumaric acid into the reactor. When the temperature rises to 70°C while stirring, add acrylic acid and 4kg of initiator potassium persulfate dropwise at the same time. The reaction time is 2h; Neutralize to neutral with 125kg sodium hydroxide solution to obtain fumaric acid-acrylic acid builder.

Embodiment 2

[0026] Add 2.5kg deionized water and 8kg fumaric acid into the reactor, and when the temperature rises to 80°C while stirring, add acrylic acid and 5kg initiator sodium persulfate dropwise at the same time, and the reaction time is 2.5h; After completion, use 125kg of sodium hydroxide solution to neutralize to neutral to obtain fumaric acid-acrylic acid builder.

Embodiment 3

[0028] Add 3kg of deionized water and 6kg of fumaric acid into the reactor. When the temperature rises to 75°C while stirring, add acrylic acid and 4kg of initiator potassium persulfate dropwise at the same time. The reaction time is 1.5h; Then neutralize to neutral with 130kg sodium hydroxide solution to obtain fumaric acid-acrylic acid builder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com