Preparation method of a non-uniform contour gradient cell capture chip

A non-uniform and contoured technology, which is applied in the field of rapid preparation of microfluidic chips, can solve the problems that microfluidic chips cannot be etched, and microfluidic chips with special-shaped channels cannot be etched, and achieve the effect of simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: (to obtain a substrate with a continuous and smooth etching surface)

[0022] A method for preparing a non-uniform equal-height gradient cell capture chip, the steps of which are:

[0023] 1. Selection and treatment of the substrate: the substrate is selected as quartz, of which the length of the quartz substrate is 75mm, the width is 25mm, and the thickness is 2mm. The selected substrate is cleaned under flowing deionized water to remove oil stains on the quartz surface, etc. impurities;

[0024] 2. Preparation of etching mask: Dry the cleaned quartz substrate in an oven at 75°C. After drying, stick protective tape on the upper and lower surfaces of the substrate, and cut it out with a laser engraving machine. One length is 60mm. 1. For an area with a width of 20mm, tear off the protective tape in this area to obtain the area to be etched;

[0025] 3. Wet etching: The wet etching refers to that after the selected substrate is prepared by etching mask, the ...

Embodiment 2

[0029] A method for preparing a non-uniform equal-height gradient cell capture chip, the steps of which are:

[0030] 1. The substrate is selected as a silicon wafer. The length of the silicon wafer substrate is 90mm, the width is 35mm, and the thickness is 2mm. The selected substrate is cleaned under flowing deionized water to remove oil and other impurities on the surface of the silicon wafer;

[0031] 2. Dry in an oven at 50°C, then paste protective tape on the upper and lower surfaces of the treated substrate, cut out an area with a length of 75mm and a width of 20mm with a laser engraving machine, and tear off the protective tape in this area Paper;

[0032] 3. Put the mask-embedded substrate into the etching solution by rotating the fixture at a constant speed of 0.6mm / min, so that the rotation angle of the substrate in the etching solution ranges from 0° to 90°, etching for 200 minutes, at this time, the etching surface of the substrate is a smooth gradient surface wit...

Embodiment 3

[0035] Example 3: (obtaining a substrate with a stepped etched surface)

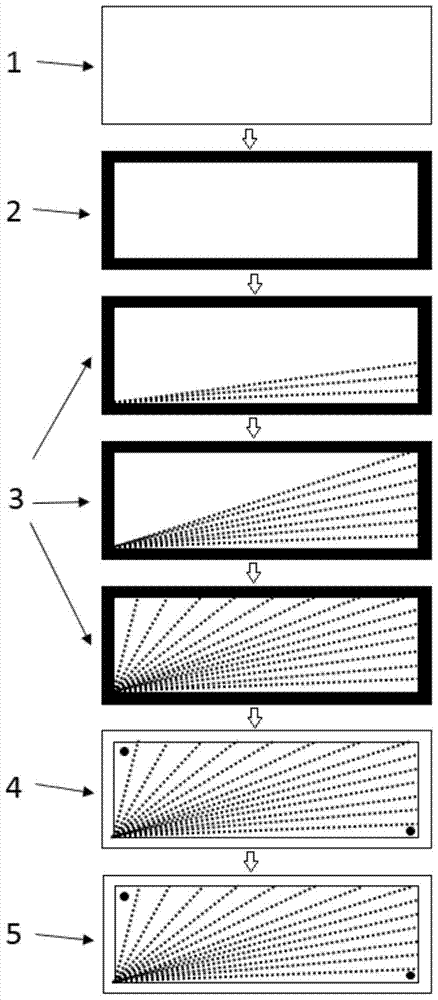

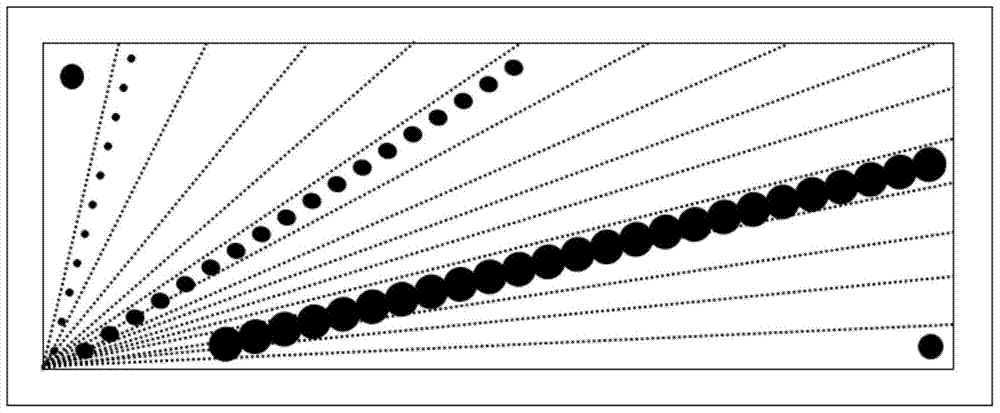

[0036] Such as figure 1 Shown, a kind of preparation method of heterogeneous contour gradient cell capture chip, its steps are:

[0037] 1. The substrate is selected as glass. The length of the glass substrate is 75mm, the width is 25mm, and the thickness is 2mm. The selected substrate is cleaned under flowing deionized water to remove oil and other impurities on the glass surface;

[0038]2. Dry in an oven at 100°C, then stick protective adhesive tape on the upper and lower surfaces of the treated substrate, cut out an area with a length of 60mm and a width of 15mm with a laser engraving machine, and tear off the protection of this area gummed paper;

[0039] 3. Put the mask-embedded substrate into the etching solution by rotating the jig at a rotation rate of 0.3 mm / min, so that the rotation angle of the substrate in the etching solution is from 0° to 90° °, etch for 290 minutes, and rotate for 50 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com