High-strength, high-elasticity and high-conductivity copper alloy

A copper alloy, high-elasticity technology, used in semiconductor devices, semiconductor/solid-state device parts, electrical components, etc., can solve problems such as low yield strength and inability to meet the performance requirements of copper alloy strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

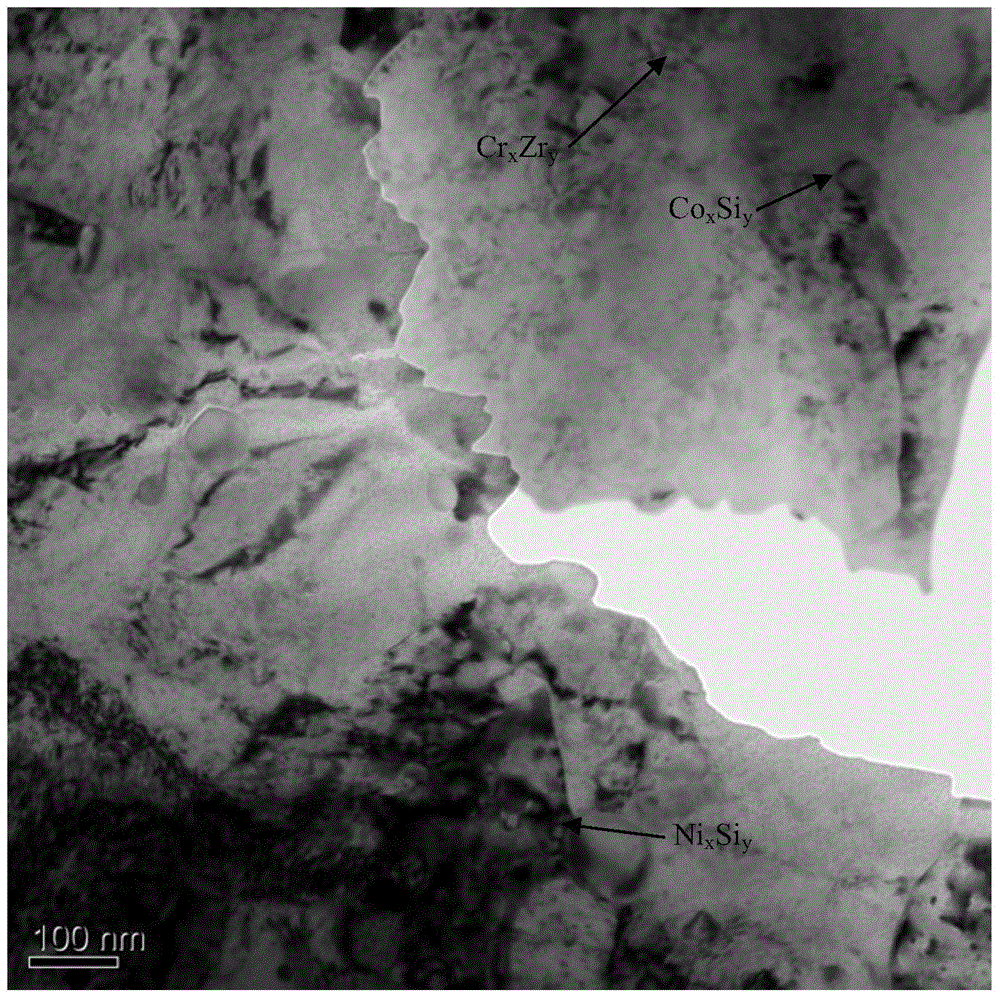

Image

Examples

Embodiment Construction

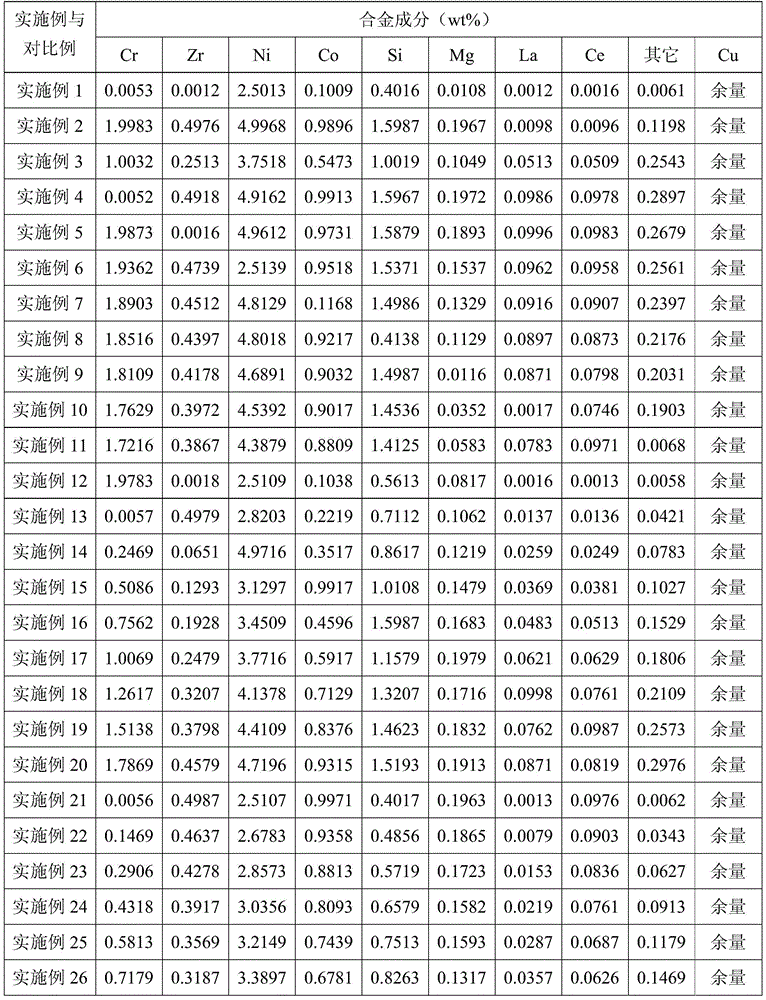

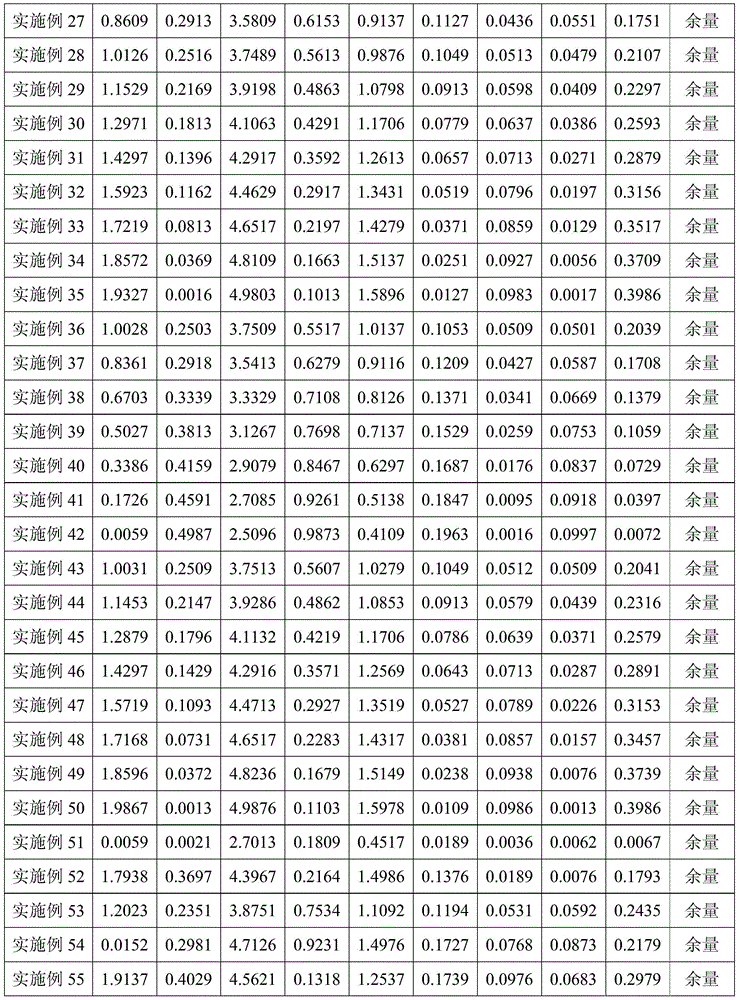

[0039] The present invention will be further described in detail below in conjunction with examples and comparative examples.

[0040] 58 example alloys and 1 comparative example alloy (C70250) were selected, all of which were processed into finished strip products with a thickness of 0.25 mm by the preparation method of the present invention. The technological process for preparing the high-strength, high-elasticity and high-conductivity copper alloy strip described in the present invention is: batching→melting and casting→sawing→heating→hot rolling→solution and quenching treatment→face milling→primary cold rolling→secondary solid solution Treatment → secondary cold rolling → primary aging treatment → tertiary cold rolling → secondary aging treatment → tension leveling, specifically including the following steps:

[0041] 1) Batching and melting and casting: prepare raw materials and batching according to the chemical composition of the alloy, and use an electromagnetic induc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com