Method and device for automatically pressing pellets and placing pressed powder pellets in laser cladding process

A technology of powder pressing and laser cladding, which is applied in metal material coating process, coating, etc., can solve the problems of low automation level, achieve good versatility, high automation, and meet cladding requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

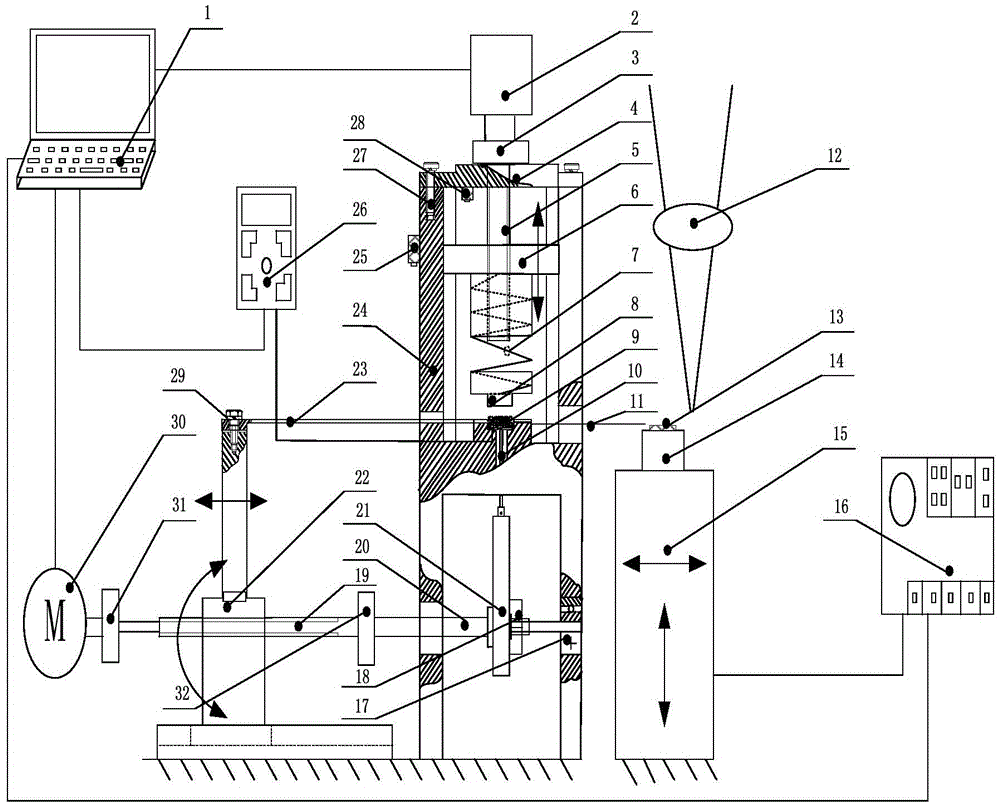

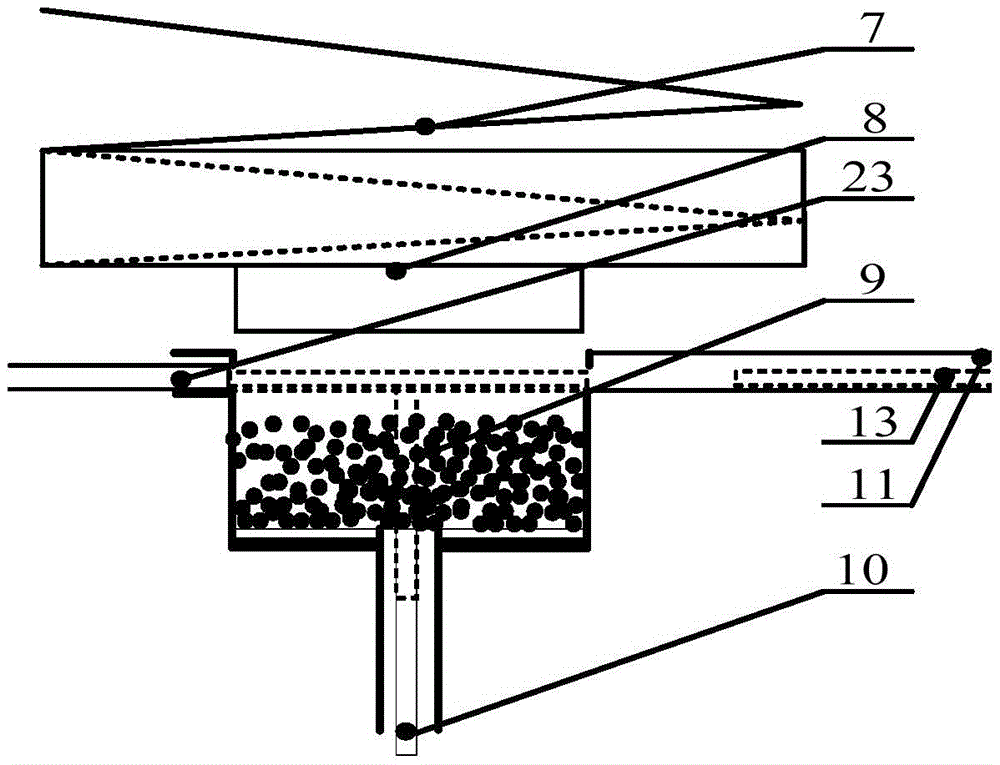

[0037] Such as figure 1 , as shown in 2.

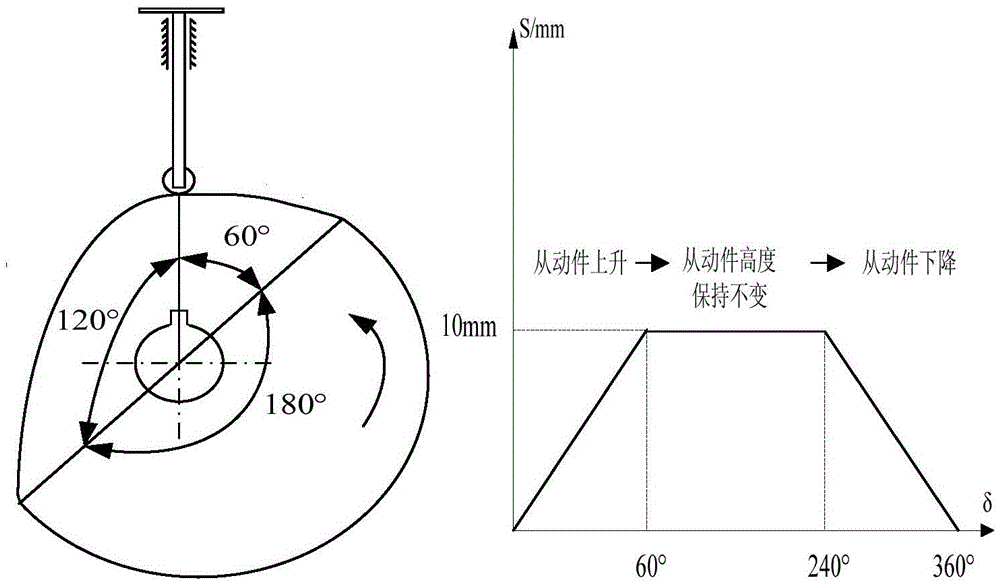

[0038] A device for automatically pressing and placing powder pressing during laser cladding, which mainly includes a computer system, a servo motor, power equipment, a powder pressing mechanism, a cam transmission mechanism and a screw transmission mechanism; the servo motor 30, Power equipment 2 is all connected with described computer system 1; Described powder tabletting mechanism comprises power equipment 2, speed reducer 3. End cover 4. Rotating lead screw 5. Movable nut 6, mold spring 7 and pressure head 8, power equipment 2 and reducer 3 bolts after connection 27 is vertically fixed on the end cover 4, the movable nut 6 is placed in the guide groove of the base 24, and can move up and down along the guide groove, and the mold spring 7 is pressed into the pressure head 8 and the movable nut 6 to realize the connection between the two , the computer 1 controls the power equipment 2 through the reducer 3 drives the rota...

Embodiment 2

[0040] A method of automatic tableting and placing powder tableting during laser cladding, taking the Ni / WC powder tableting coating on the surface of AZ91D magnesium alloy (length: 40mm, width: 40mm, height: 5mm) as an example , the method steps are as follows:

[0041] A. Grind the AZ91D magnesium alloy substrate to be clad with sandpaper and ultrasonically clean it with alcohol or acetone for 5-10 minutes to remove oil stains and dirt on the surface;

[0042] B. Place the processed cladding substrate on the motion platform, and place it in the working area of the guide groove under the control of the controller;

[0043] C. The computer sends out a signal to make the power equipment start to rotate and turn the screw in reducer Driven by the in-situ rotation, the moving nut drives the indenter to move down, and the Ni / WC powder manually placed in the accurately weighed groove is pressed down;

[0044] D. When the press-in pressure reaches 28Mpa, the digital display p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com