Concrete abrasion resistance test system and method

A technology of test system and concrete specimen, which is applied in the field of test system, can solve problems such as troublesome labor intensity, manpower consumption, leakage, etc., and achieve the effects of reducing labor intensity, simplifying the disassembly process, and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

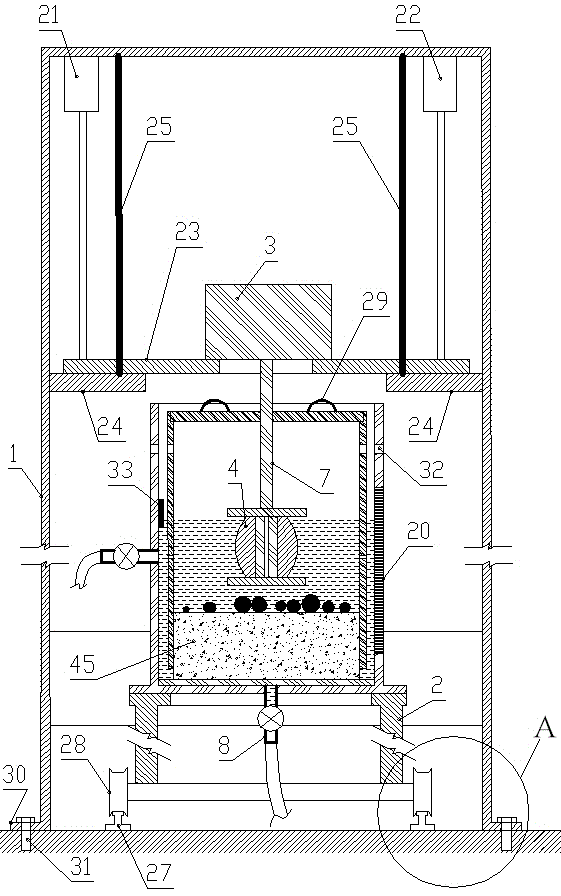

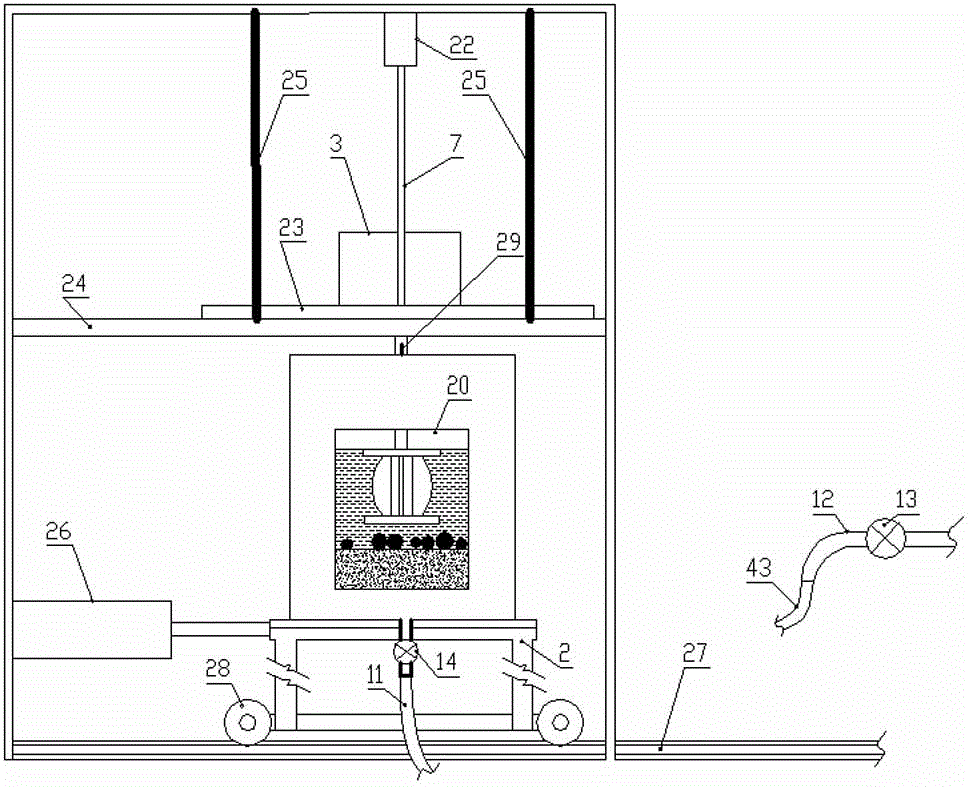

[0070] Such as Figure 1 to Figure 8 As shown, the concrete abrasion resistance test system of the present invention includes a concrete abrasion mechanism, a frame and a water inlet mechanism.

[0071] The frame includes an outer fixed frame 1 and an inner mobile frame 2.

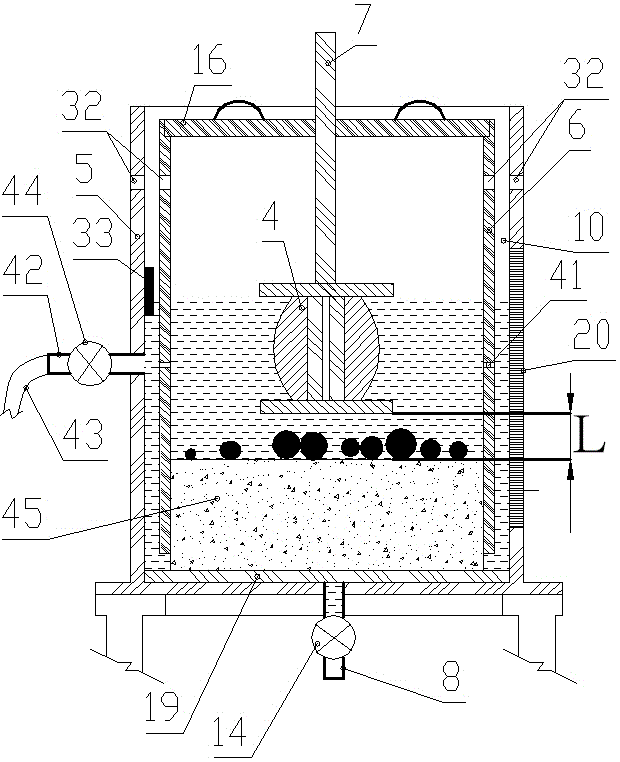

[0072] The concrete grinding mechanism includes a stirring motor 3 arranged on the outer fixed frame 1 and a cylindrical body arranged on the inner moving frame 2, and the stirring paddle 4 is connected to the shaft of the stirring motor 3.

[0073] The cylinder body includes a steel outer cylinder body 5 and an inner cylinder body 6 made of wear-resistant plastic placed in the outer cylinder body 5. There is a gap 10 with a circular cross section between the outer cylinder body 5 and the inner cylinder body 6; the outer cylinder body 5 has a bottom plate (the outer cylinder body and the bottom plate are integrally set), and the inner cylinder body 6 is open up and down; specifically, the outer cylinder b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com