Gas chromatography full-automatic gas constant-pressure sample-feeding apparatus and control method

A technology of gas chromatography and sampling device, which is applied in the field of automatic gas constant pressure sampling device and control of gas chromatography, can solve the problems of uneven sampling pressure, low degree of automation, influence of precision, etc., and achieves guaranteed precision and stable repeatability, reduce workload, and improve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

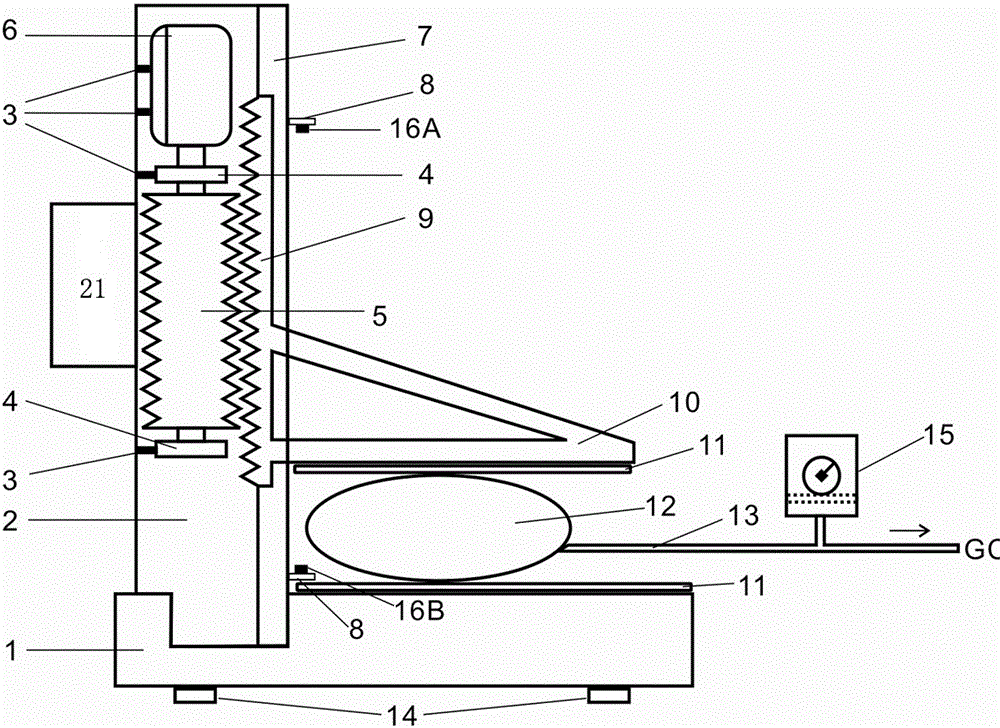

[0038] When the gas sampling bag or balloon is filled with samples and needs to be analyzed, the outlet of the sampling bag or balloon is connected to the pressure measurement controller 15 through a three-way section with the air guide tube 13, and the other end is connected to the gas chromatographic sample inlet. For easy connection, The air guide tube 13 is made of corrosion-resistant material that is easy to bend, and generally selects a fluorine rubber hose or a stainless steel tube. The connected sampling bag or balloon is placed on the horizontal base plate 1, the level of the table is adjusted through the adjustable feet 14, and the vial embedded in the horizontal base plate 1 is observed for confirmation.

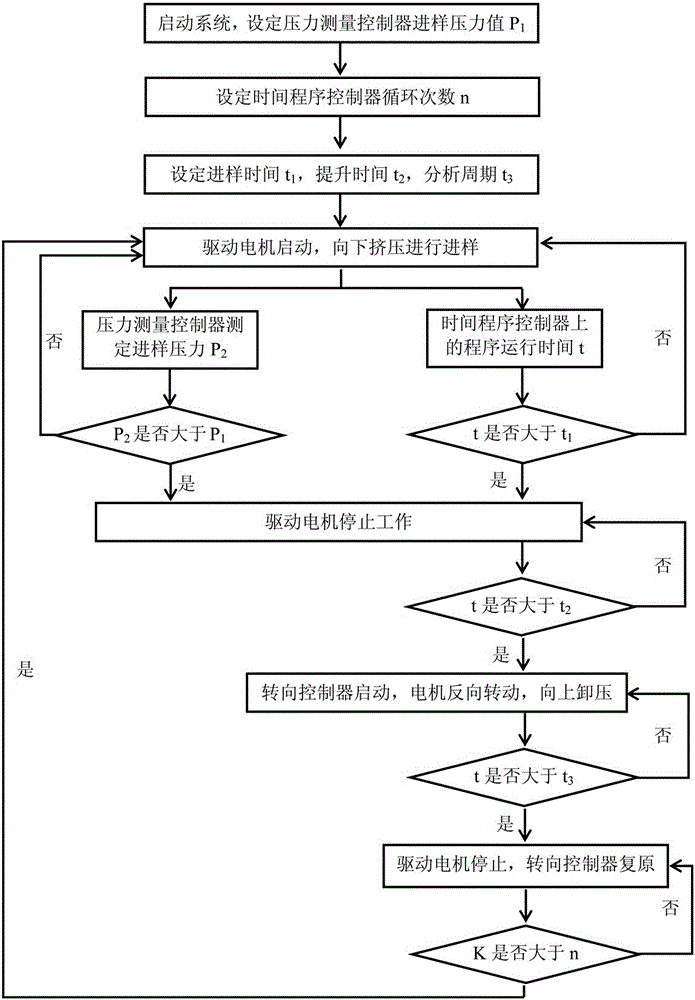

[0039] Turn on the device power supply 20 switch, set the sample injection pressure value P1 on the pressure measurement controller 15, and set the time program t1, t2, t3 and the number of samples n to be analyzed on the time program controller 18 at the same time...

Embodiment 2

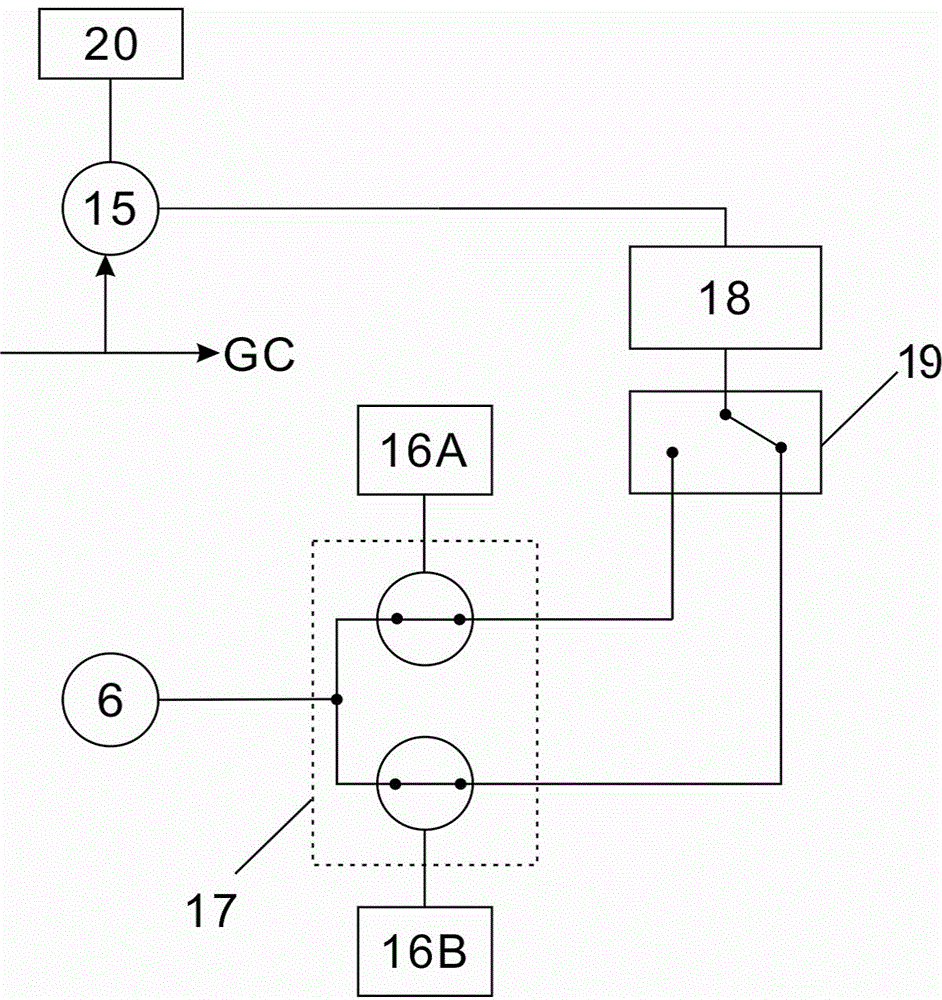

[0042] Set the pressure value P1 of the gas sample injection to be slightly higher than the atmospheric pressure P0, and usually set P1 to 105~150kPa. At this time, if the measured value P2 displayed by the pressure measurement controller 15 is lower than the set pressure value P1, a positive signal difference is generated, the internal relay 17 of the pressure measurement controller 15 is connected to the drive motor 6, and the motor starts to work, and the gas sampling bag or The balloon is squeezed and gas begins to flow into the GC sample inlet. With the continuous extrusion, the pressure of the sample gas is also gradually increased until P2>P1, the internal relay 17 of the pressure measurement controller 15 disconnects the drive motor 6, stops the extrusion of the gas sampling bag or balloon, and maintains the device at the same time. When the measured pressure value P2 decreases again, the internal relay 17 of the pressure measurement controller 15 turns on the motor sw...

Embodiment 3

[0045] On the time program controller 18, set the pressure injection time point t1, the pressure relief time point t2, and the analysis cycle time point t3, and set the number of cycles n according to the number of samples, thereby completing a time program setting. Among them, the pressurized sampling time can be set according to the size of the sample quantitative loop on the gas chromatography sampling valve and the length of the external connecting pipeline. Usually, t1 is generally set as a time point within 3 to 10 minutes , to ensure that all the sampling lines are completely purged and filled with the sample gas as the basic principle. During the period of pressurized sample injection, the motor steering controller 19 controls the motor to rotate forward, and the extruding member 10 moves down slowly to squeeze the gas sampling bag or balloon to realize sample injection. The pressure relief time point t2 is determined based on the required injection time and the time f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com