Solar cell module and preparation method thereof

A technology of solar cells and components, applied in the field of solar cells, can solve the problems of easy cracking of cells, non-green materials, and high cost of TPT backplanes, and achieve the effects of ensuring photoelectric conversion efficiency, simple and easy preparation, and high photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

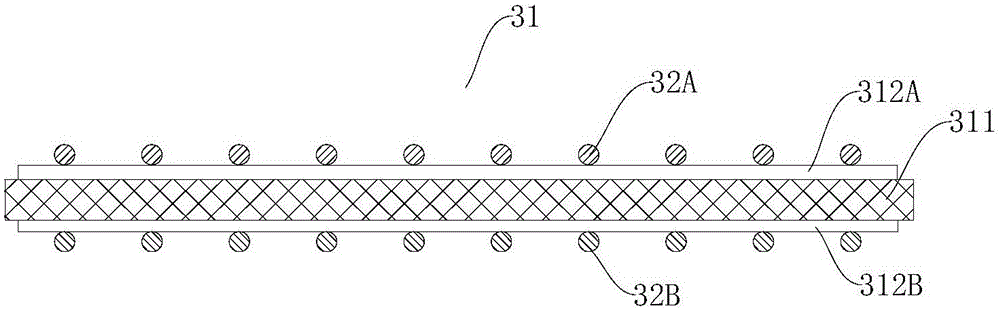

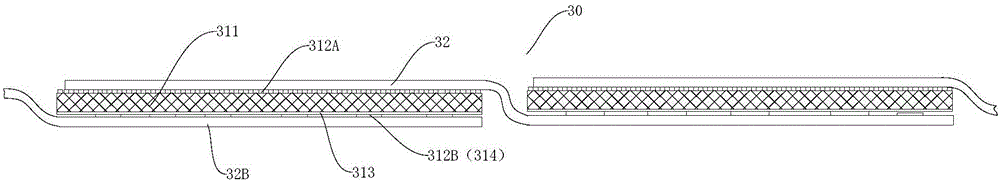

[0132] During the preparation process of the solar cell module provided by the present application, the conductive wire 32 can be welded to the sub-grid line 312 and the back electrode on the battery sheet first, and then each layer is stacked and laminated.

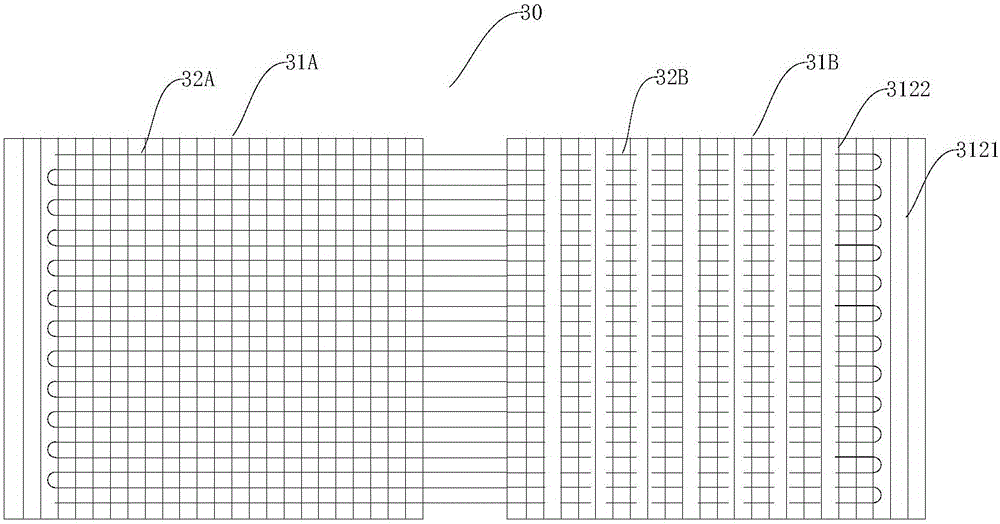

[0133] In a specific embodiment of the present invention, the solar cell module 100 includes an upper cover plate 10 , a front adhesive film layer 20 , a cell array 30 , a back adhesive film layer 40 and a water vapor insulating back sheet 50 . The battery slice array 30 includes a plurality of battery slices 31, and the adjacent battery slices 31 are connected by a plurality of conductive wires 32. The conductive wires 32 are formed by metal wires S extending back and forth between the surfaces of adjacent battery slices. The conductive wires 32 Welding with the auxiliary grid lines, the front adhesive film layer 20 is in direct contact with the conductive lines 32 and fills between adjacent conductive lines 32 .

[013...

example 1

[0174] Example 1 is used to illustrate an example of the solar cell module 100 of the present application and its manufacturing method.

[0175] (1) Preparation of conductive wire

[0176] Attach a layer of 50%Sn-48%Bi-1.5%Ag-0.5%Cu alloy layer (melting point is 160 ℃) on the surface of the copper wire, wherein the cross-sectional area of the copper wire is 0.04mm 2 , the thickness of the alloy layer is 16 microns, thereby making the conductive wire.

[0177] (2) Preparation of solar cell module 100

[0178] Provide a POE film layer with a size of 1630×980×0.5mm (melting temperature is 65°C), and accordingly provide a glass plate with a size of 1633×985×3mm and 60 pieces of polycrystalline silicon cells with a size of 156×156×0.21mm Tablet 31. The battery sheet 31 has 91 auxiliary grid lines (made of silver, with a width of 60 microns and a thickness of 9 microns), each auxiliary grid line basically runs through the battery sheet 31 in the longitudinal direction, and the ...

example 2

[0181] The difference between example 2 and example 1 is:

[0182] Arrange the battery slices 31 in the form of matrix, and between two adjacent battery slices 31, adopt such as Figure 14 In the drawing method shown, 15 parallel metal wires are tensioned through the clip at the end of each metal wire, and the battery sheet is flattened. The tension of the clip is 2N. Each of the 15 parallel metal wires is It is individually welded to the sub-grid on the front of one battery sheet 31 and welded to the back electrode on the back of the other battery sheet, and the distance between adjacent conductive lines that are parallel to each other is 9.9 mm. Thus, a solar cell module was produced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com