A kind of multi-dimensional heterogeneous nanostructure lithium battery cathode material and preparation method thereof

A nanostructure and positive electrode material technology, applied in battery electrodes, structural parts, circuits, etc., can solve problems such as low conductivity, capacity fading, and easy agglomeration, and achieve the effects of inhibiting electrode structure damage, increasing layer spacing, and buffering stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

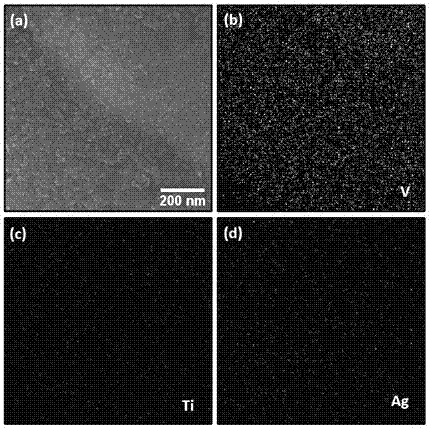

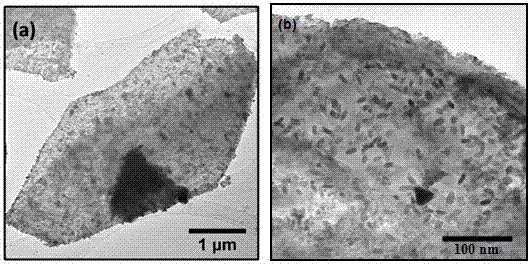

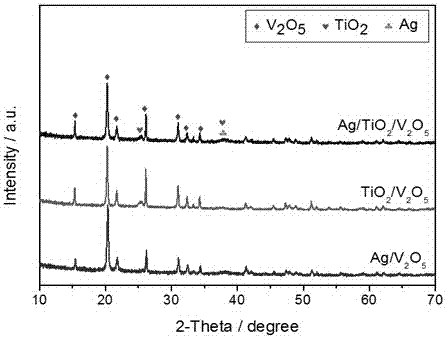

[0040] for Nano V 2 o 5 The two major defects of low conductivity and easy agglomeration of nanosheets, through the secondary phase of high conductivity silver nanoparticles and TiO 2 Co-doping of nanorods, this example provides a V 2 o 5 Nanosheet-TiO 2 The nanorod-Ag nanoparticle multidimensional heterogeneous nanostructure lithium battery cathode material, using its outstanding synergistic effect and unique multidimensional heterogeneous structure, exerts excellent comprehensive electrochemical performance.

[0041] This example provides the V 2 o 5 Nanosheet-TiO 2 Nanorod-Ag nanoparticles multidimensional heterogeneous nanostructure lithium battery cathode material is composed of Ag, TiO 2 and V 2 o 5 A multidimensional heterogeneous nanostructure composed of three components with a weight ratio of 5:15:100, the preparation method is as follows:

[0042] (1) Put 1.8g commercial V 2 o 5 powder and 22g (NH 4 ) 2 S 2 o 8 Add it into 180mL deionized water, stir...

Embodiment 2

[0048] The difference between this example and Example 1 is step (4): the Ag and TiO 2 Both solutions were dissolved in THF solution separately to obtain 0.5 mg mL –1 THF solution, then according to Ag:TiO 2 :V 2 o 5 =8:12:100 weight ratio mixed and stirred for 8 hours, under the driving force of reducing the free energy of the system, assembled into V 2 o 5 Nanosheets—TiO 2 Nanorod—Ag nanoparticle multidimensional heterogeneous nanostructure lithium battery cathode material. Then washed and centrifuged, and dried under vacuum at 60°C for 12 hours.

Embodiment 3

[0050] The difference between this example and Example 1 and 2 is step (1): the 50mgV 2 o 5 The powder was added to 50ml of formamide solution, stirred for 12h to make it fully mixed. The resulting suspension was sonicated for 3 days at room temperature. Then, the supernatant was centrifuged, washed with ethanol, and dried at 70°C to obtain the stripped V 2 o 5 Nanosheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com