Z-axis tool setting gauge

A tool setting instrument and Z-axis technology, applied in the direction of instruments, signal transmission systems, automatic control devices, etc., can solve the problems of reducing the service life of the tool head, high cost, high technical requirements, etc., to avoid interference, avoid serious damage, Solve cumbersome effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

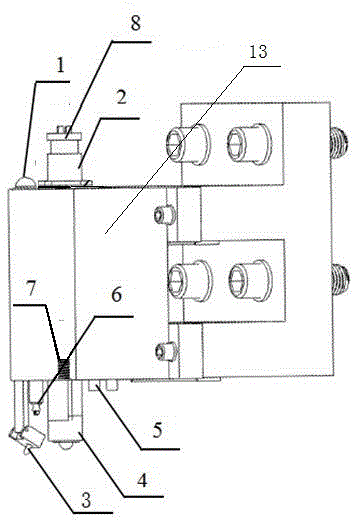

[0027] Accompanying drawing is a kind of specific embodiment of the present invention.

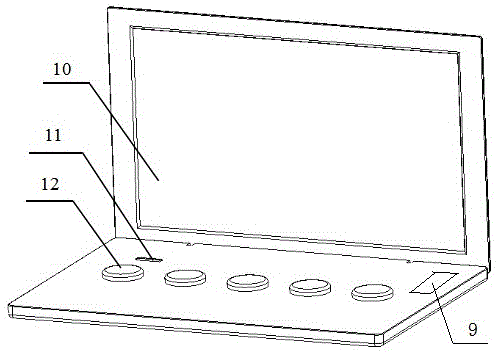

[0028] The Z-axis tool setting instrument of the present invention includes a level 1, a single-chip microcomputer 2, a camera 3, a ball head pressure sensor 4, an ultrasonic ranging sensor 5, an LED light 6, a Z-axis miniature sliding table 7, a transmitting module device 8, and a wireless receiver. A module device 9 , a liquid crystal display 10 , a physical button 11 and a prompt light 12 .

[0029] The Z-axis tool setting instrument of the present invention includes three main functional parts of a monitoring operation part, an acquisition work part and a data transmission part connected to each other, and the monitoring operation part includes a liquid crystal display screen 10 connected to each other, a physical control button 11 and a wireless receiving module Device 9; the acquisition part includes a level 1 installed on the bracket 13, a ball pressure sensor 4, an ultrasonic dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com