A kind of emulsion sizing agent for carbon fiber with low contact angle and low moisture regain and its preparation and application

A contact angle and carbon fiber technology, which is applied in carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problems of insufficient attention on contact angle, high moisture regain of carbon fiber, and excessive components, and achieve long storage period, low moisture regain, The effect of high bonding strength

Active Publication Date: 2019-08-13

CHINA PETROLEUM & CHEM CORP +1

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This type of sizing agent does not pay enough attention to the contact angle between carbon fiber and matrix resin, and because it is prepared by external emulsification method, there are too many components such as surfactant and curing agent in the formula, and the moisture regain of carbon fiber is relatively high.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0048] The present invention will be described in detail through the following examples, which will help the understanding of the present invention, but do not limit the content of the present invention.

[0049] The raw materials in the following examples are commercially available unless otherwise specified.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Login to View More

Abstract

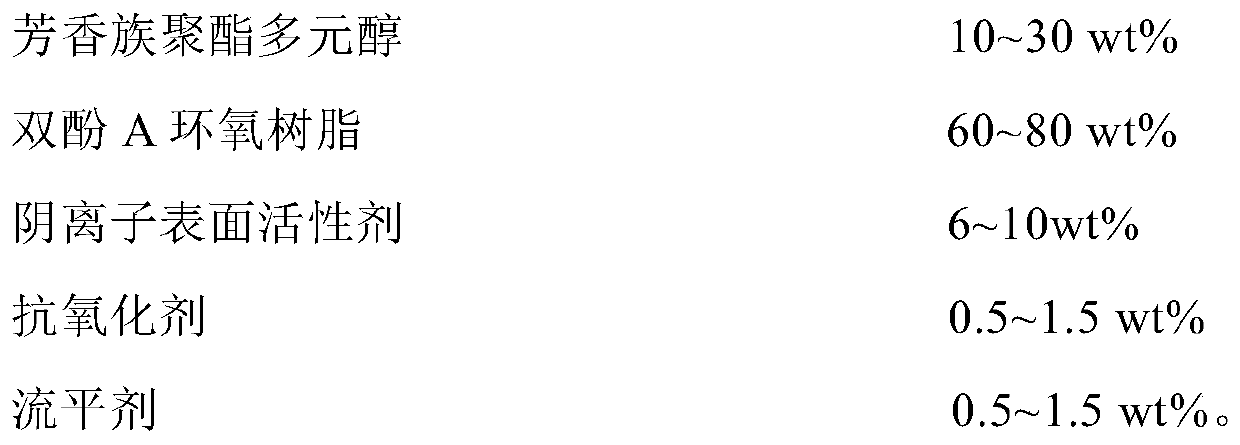

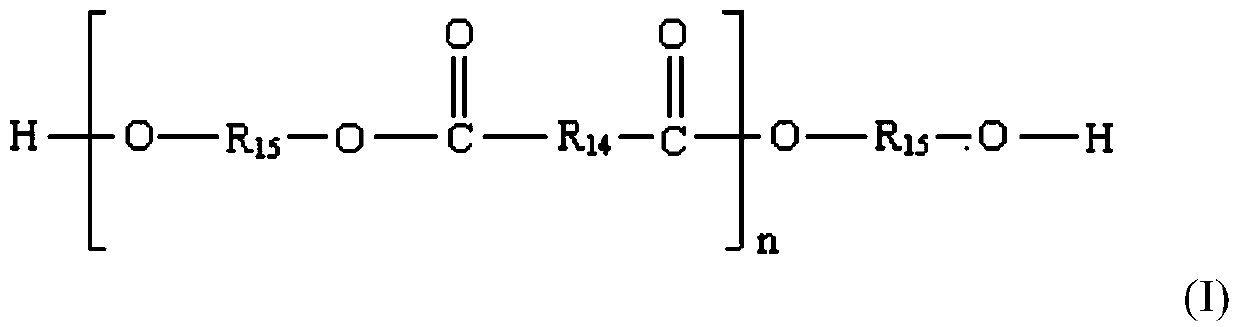

An emulsion sizing agent used for carbon fibers with a small contact angle and a low moisture regain is disclosed. The emulsion sizing agent comprises main agents and deionized water. The mass ratio of the main agents to the deionized water is (35:65)-(55:45). The main agents comprise 10-30 wt% of aromatic polyester polyol, 60-80 wt% of bisphenol A epoxy resin, 6-10 wt% of an anionic surfactant, 0.5-1.5 wt% of an antioxidant and 0.5-1.5 wt% of a leveling agent. The carbon fibers sized by utilizing the emulsion sizing agent are small in contact angles with substrate resin, high in infiltration speed, high in adsorbability, high in interface bonding strength with composite materials, extremely low in moisture regain, low in requirements on carbon fiber storage environments, capable of being stored for long time without influences on physical performance of the fibers and high in resistance to heat and humidity, and can be applied in a plurality of complex environment conditions, such as aviation and offshore operation. A preparing method and a using method of the emulsion sizing agent used for the carbon fibers are also disclosed.

Description

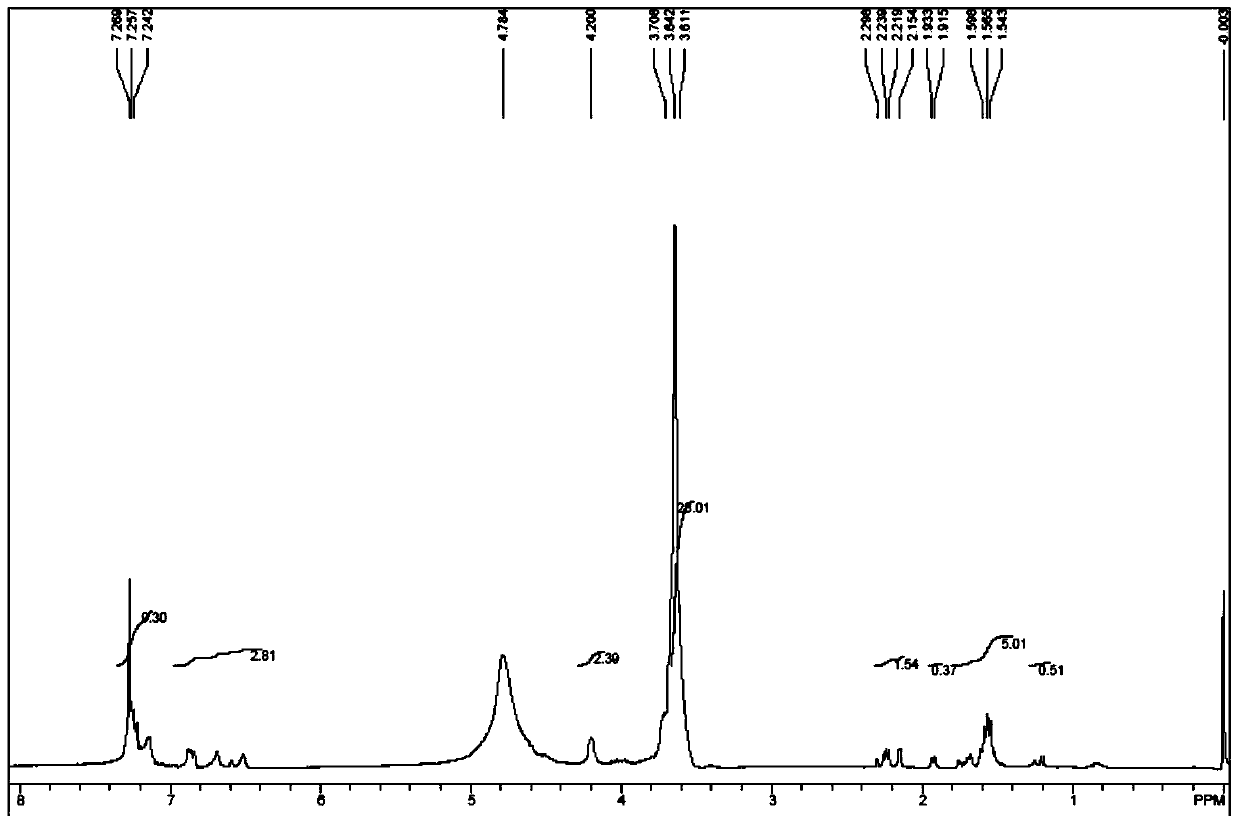

technical field [0001] The invention belongs to the field of carbon fiber chemical industry, and in particular relates to a low contact angle and low moisture regain carbon fiber emulsion sizing agent and its preparation and application. Background technique [0002] Carbon fiber composites are not only indispensable new materials for aerospace and military industries, but also have outstanding social and economic benefits in civil industries such as transportation, infrastructure, new energy and environmental governance. In the forming process of carbon fiber composite materials, various technical performance indicators of carbon fiber have an important impact on the physical comprehensive performance and stability of composite materials, which determine the practicability and economical efficiency of composite materials. [0003] The contact angle between carbon fiber and matrix resin is an important factor affecting the ease of preparation of composite materials and the s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D06M15/55D06M15/507C08J5/06C08K9/08C08K7/06D06M101/40

Inventor 季春晓黄翔宇曹阿民刘瑞超张捷王平田晓婧周新露常丽刘礼华

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com