Resonant silencer

A muffler and resonant cavity technology, applied in muffler devices, machines/engines, engine components, etc., can solve the problems that the muffler cannot achieve the noise reduction effect, the volume of the muffler is large, and the noise reduction cost is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

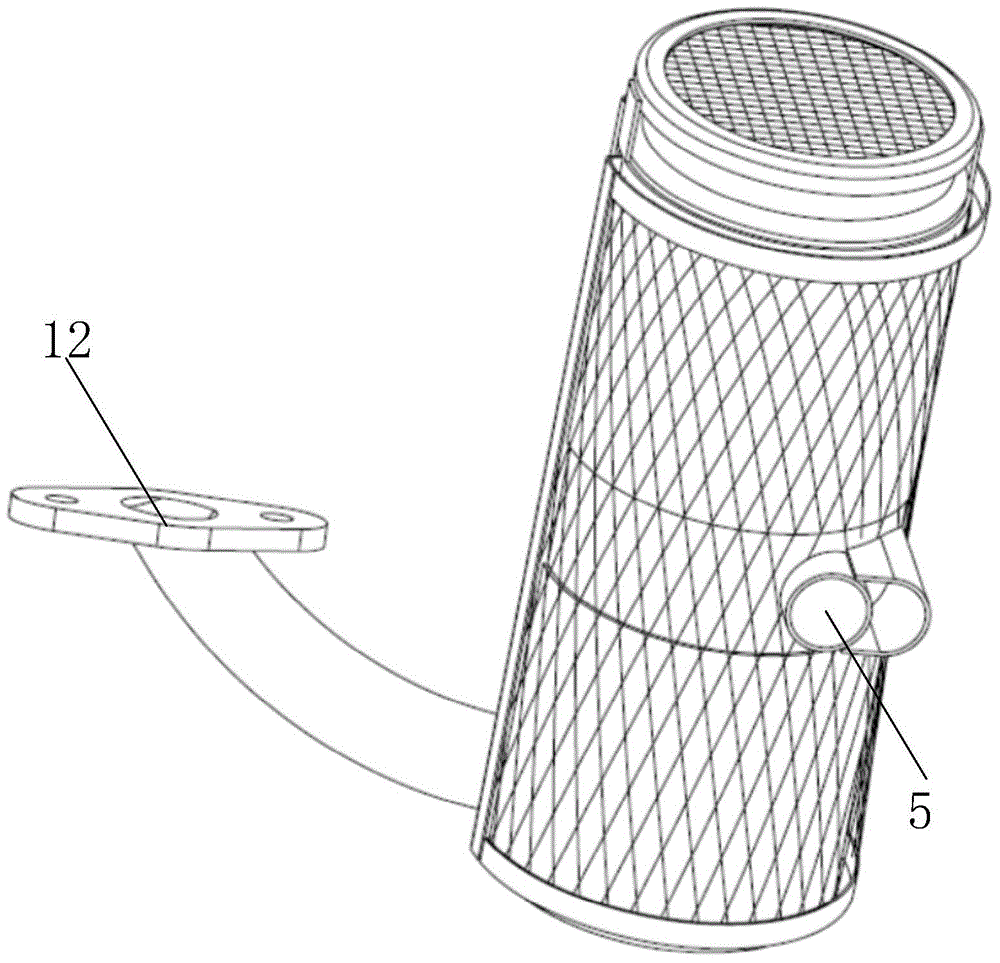

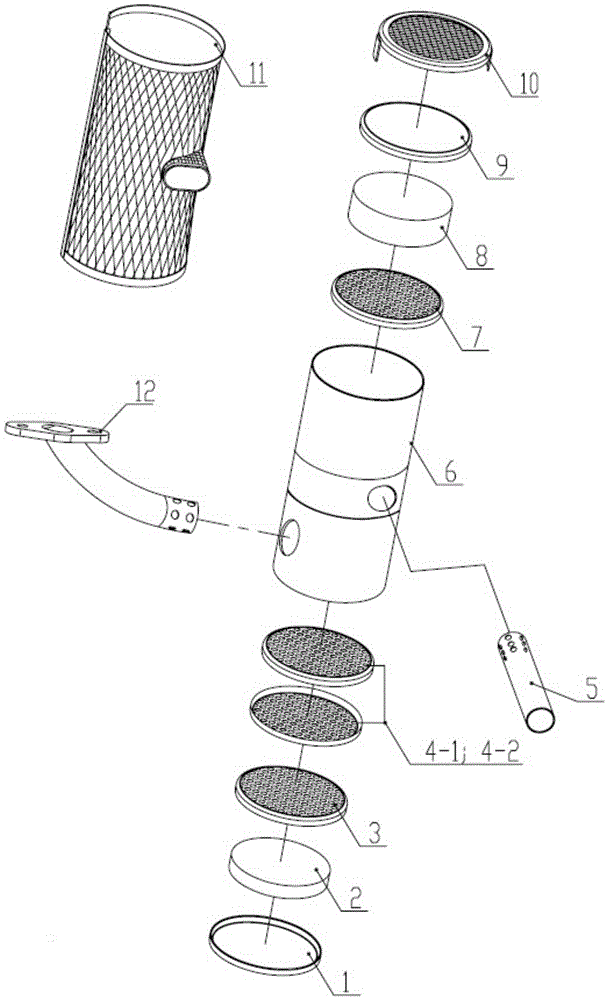

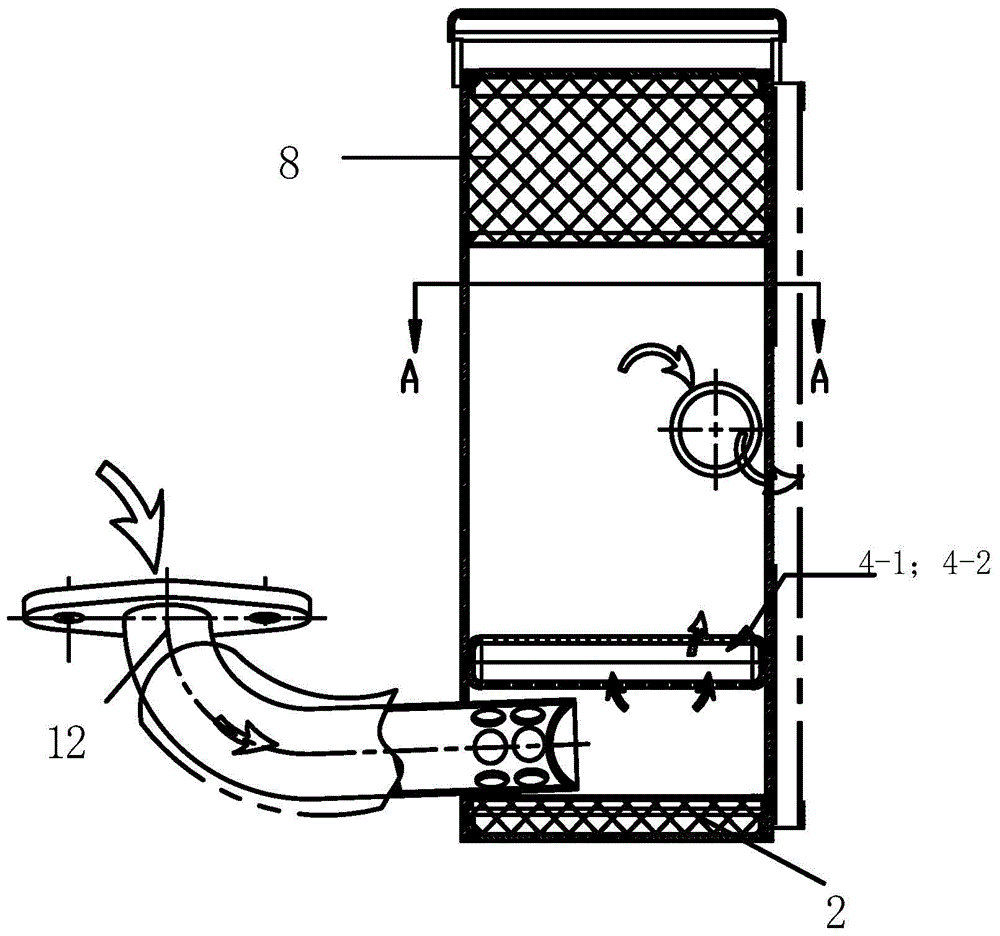

[0017] Such as figure 1 and figure 2 As shown, the resonance muffler is an assembly composed of metal plates. This embodiment shows that it adopts a cylindrical shape, but it is not limited to this, and it can also be made into a square, oblate or other outer shell. . The main components include:

[0018] Part 1, the lower end cap used to seal the cylinder port;

[0019] Part 2, the sound-absorbing layer near the air inlet made of fireproof fiber or hollow structural material;

[0020] Item 3, the microporous thin metal plate used to seal the sound-absorbing layer;

[0021] Item 4-1 and Item 4-2, two microporous thin metal plates with different apertures constituting the resonant cavity;

[0022] Part 5, the air outlet pipe of the muffler, the air inlet end of the pipe body is equipped with a number of suitable air inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com