Photoinduced dielectrophoresis assembly chip and method for constructing gradient-structure gel complex

A technology of dielectrophoresis and combination, which is applied in the field of biomedicine, can solve the problem that the construction of exogenous factor concentration gradient and cell concentration gradient is difficult to realize at the same time, so as to reduce complexity and cost, reduce lateral resistance, and maintain active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

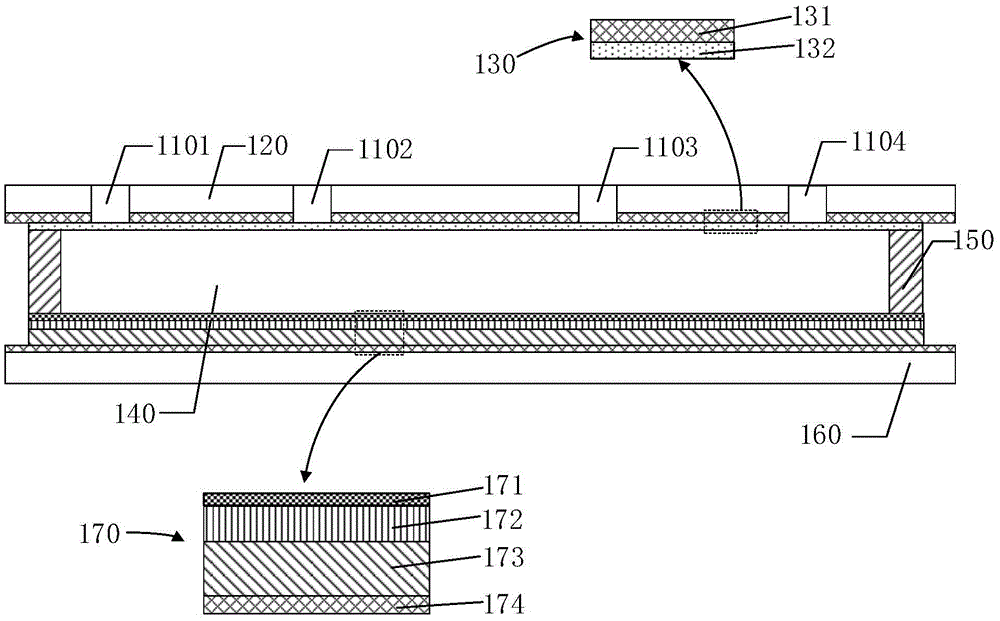

[0038] Such as figure 1 As shown, this embodiment 1 provides a photo-dielectrophoresis assembly chip, including: a number of injection ports (first injection port 1101, second injection port 1102, third injection port 1103, fourth injection port 1104), and several gel micro-blocks (first gel micro-block 191, second gel micro-block 192, and third gel micro-block 193) are adapted to be respectively injected into the microfluidic cavity 140 through corresponding injection ports; The upper end of the microfluidic cavity 140 is provided with an electrode layer 130, and the lower end is provided with a dummy photoelectrode forming layer 170.

[0039] Specifically, the electrode layer 130 includes a double-layer structure, from top to bottom: an upper transparent conductive layer 131, a hydrophobic coating 132; the virtual photoelectrode forming layer 170 is a multilayer structure, from top to bottom In order: the hydrophilic coating 171, the passivation layer 172, the photoconductive l...

Embodiment 2

[0044] Before assembling the structurally graded gel assembly, it is also necessary to prepare corresponding gel micro-blocks.

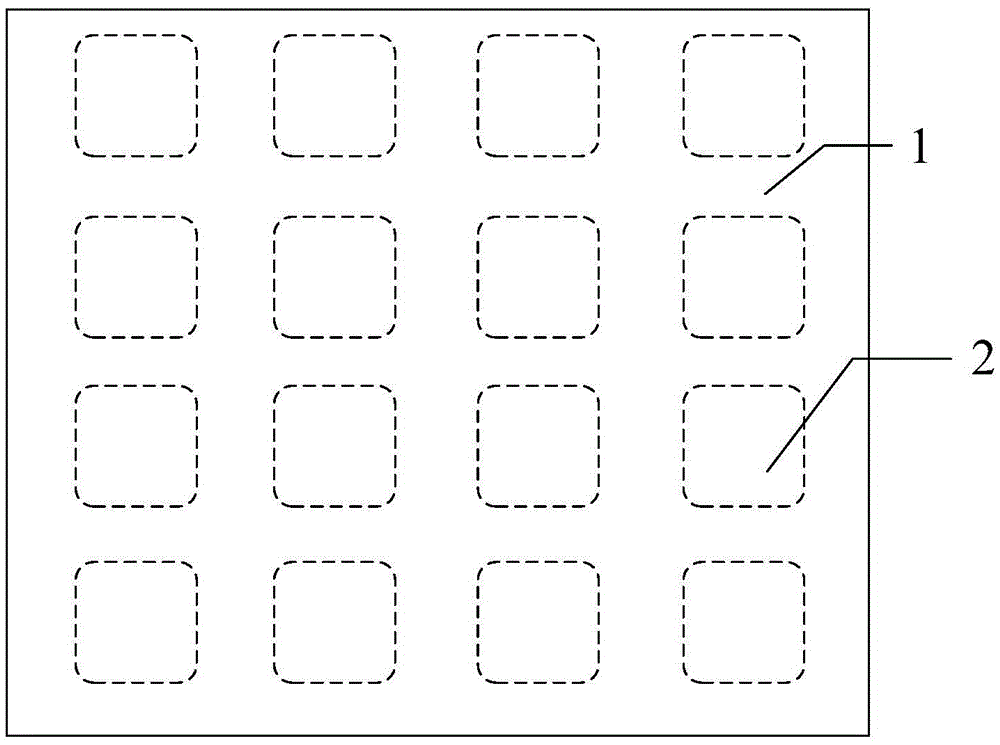

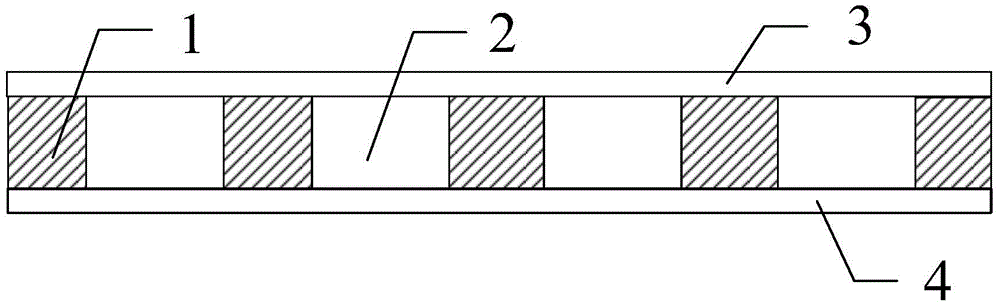

[0045] Such as figure 2 with image 3 As shown, the mold for preparing gel micro-blocks used in this embodiment includes a solid area 1, a hollow area 2, an upper cover sheet 3, and a lower cover sheet 4. First, the liquid gel precursor solution is injected into the hollow area 2 of the mold, and then through the gelation process, solid gel micro-blocks are formed in the hollow area of the mold, and then the entire mold device (including upper and lower Coverslips) placed in phosphate buffer solution, after a few minutes of soaking, remove the upper and lower coverslips. Then the middle layer of the mold with the solid gel micro-blocks was taken out separately and put into a petri dish filled with a new phosphate buffer solution. After several minutes of shaking, the solid gel micro-blocks in the middle layer of the mold gradually separated from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com